- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- Segments

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Segments

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

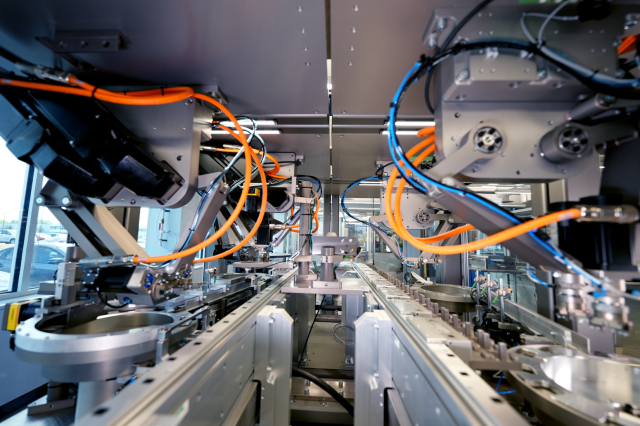

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

Configurable Platform Finder

Nulla eu luctus ante. Pellentesque nec dui ex. Pellentesque mattis fringilla libero, non volutpat ipsum porttitor et. Nullam congue, felis id porttitor fringilla, nisi risus imperdiet urna, eget posuere enim ante vitae elit. Vivamus semper sollicitudin tellus, a faucibus leo.

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

- Blog

- Symphoni

- service

- lean manufacturing

- innovations

- Tube Sets

- Dispensing

- Biochips

- Biosensors

- Assays

- Diagnostics

- Risk

- Risk Assembly Symphoni Project Management Product Design

- Contract Manufacturing

- REM

- Medical Manufacturing

- AI

- Assembly

- Product Design

- Pharma

- Automation

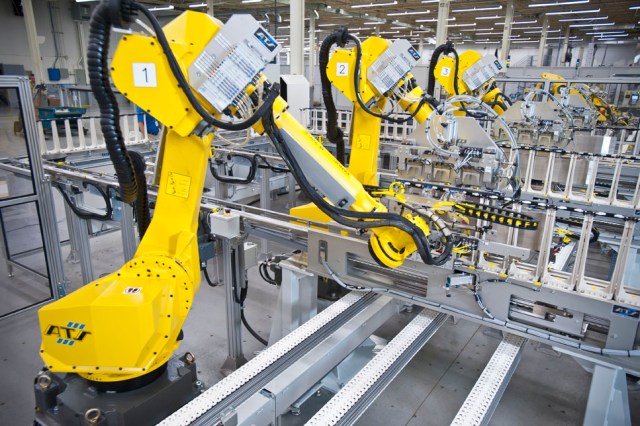

- Robotics

- Project Management

- Machines

Machines

You cannot be an expert at everything. If you try, inevitably something will go off the rails preventing your organization from realizing their initial business objectives. Many OEMs/businesses have evolved out of the full lifecycle ownership mindset. Process engineering, forensic engineering, and reliability engineering are a few of the many consulting disciplines available to support

Jordi Brown

Aug 17, 2023 • 5 min read

The Case for Pre-Engineered Automation Systems Over approximately the last 30 years, the evolution of automated systems implemented to enable advanced manufacturing has led to the proliferation of the pre-engineered automated work cell/system. In turn, this has enabled significant growth in the global deployment of automated systems throughout all facets of global manufacturing, where virtually

Hang Tran, P.Eng., M.A. Sc., PMP

Aug 1, 2023 • 4 min read

You can’t be an expert at everything. For this reason, Original Equipment Manufacturers (OEM) are constantly faced with meeting various product commercialization issues. Between streamlining supply chains, minimizing material handling, and consolidating vendor selections to remain competitive, there’s a lot that goes into improving your bottom line. OEMs base their value on customizing their product

Jordi Brown

Jul 17, 2023 • 5 min read

As we roll out our 2023 operational plans, the medical device industry is set to witness some exciting developments and trends. Here are the top five trends to keep an eye on throughout the year: 1 – Artificial Intelligence and Machine Learning AI and machine learning (ML) are already being used in a variety of

Brandon Cole

Mar 10, 2023 • 7 min read

Survivalists say that abled bodies require a healthy supply of food, water, air, and shelter to survive. But to many diabetics, like myself, insulin must be added to the list. As a result, I’ve found that insulin dependent people are often fascinated by the technologies that replace the function of their MIA pancreata. This fascination

ATS Life Sciences

Feb 23, 2023 • 7 min read

Increased output, greater product consistency, and decreased costs are just some of the benefits of improved productivity. But knowing where to begin on your efficiency journey can be a challenge. That’s why we’ve come up with 5 Ways to Improve Productivity in Pharma Manufacturing, an easy-a-to-implement guide for achieving long-term success. 1 – Optimize and

ATS Life Sciences

Feb 23, 2023 • 4 min read

It’s tough out there and the competition is fierce, no matter what industry you’re in or what product you’re introducing to meet a need – or create one. It’s a universal rule that whoever gets to market first gets the lion’s share, so there’s plenty of pressure to make each of your 24 hours a

Ryan Babel

Dec 16, 2022 • 5 min read

To increase profit you can either sell at a higher price or cut the cost of production. Easy, right? When conventional responses don’t address modern and complex issues it’s time to consider new approaches. If you’re not moving to a state-of-the-art facility or if your procurement is focused on security versus cost, at least in

ATS Life Sciences

Dec 7, 2022 • 4 min read

It is common for manufacturers to look for efficiencies in their lines based on linear access; but more often manufacturers today are interested in the potential of robotics because they can either be integrated into existing lines or be built as an end-to-end solution. This technology, which is common in large automotive applications, if done

Uwe Ganter

Dec 2, 2022 • 7 min read

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube