Case Studies for Medical Devices

Repetitive Equipment Manufacturing

ATS Automation can be your manufacturing partner for contract manufacturing. Our flexible workforce, project management rigor and deployment of lean manufacturing principles enable us to provide repetitive equipment manufacturing services for complex machines including medical devices. We have helped numerous clients quickly scale up to meet delivery commitments to their customer-providing manufacturing and operations services through our certified ISO 13485 global facilities. Benefits to our customers include complete product life cycle management, value add/value engineering services, supply chain optimization, burst production capacity or manufacturing flexibility, and global reach.

Driving Down Unit Costs While Improving Product Design

INDUSTRY: MEDICAL DEVICES

PRODUCT: LAB AUTOMATION

Program Notables:

- 360-unit contract over 6-year period

- Systems worth: $150K to $250K

- Peak demand capacity: 3 systems/week

- Fully validated medical device

Extended Services:

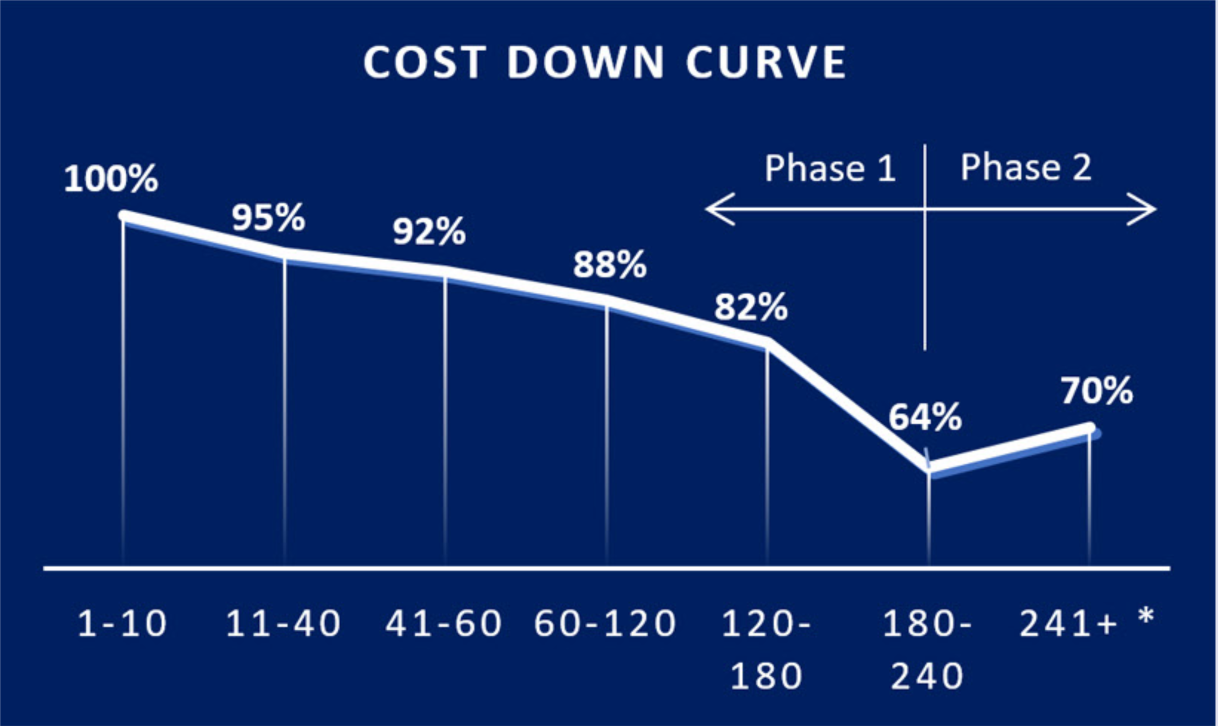

- Phase 1: ATS focused cost down engineering initiative

- Achieved 64% of original cost

- Phase 2: Next generation product development

- New control system

- 50% capacity/throughput increase

- Increased MTBI 2x (actual result 4x)

- Aesthetic and ergonomic improvements

Testimonial:

“ATS delivered significant unit cost reductions while upgrading the product feature set, BOM obsolescence, aesthetics and ergonomics.”

Results:

Ensuring On-time Delivery with a Full Life Cycle Partner for Over 18 Years

INDUSTRY: MEDICAL DEVICES

PRODUCT: LAB AUTOMATION

Program Notables:

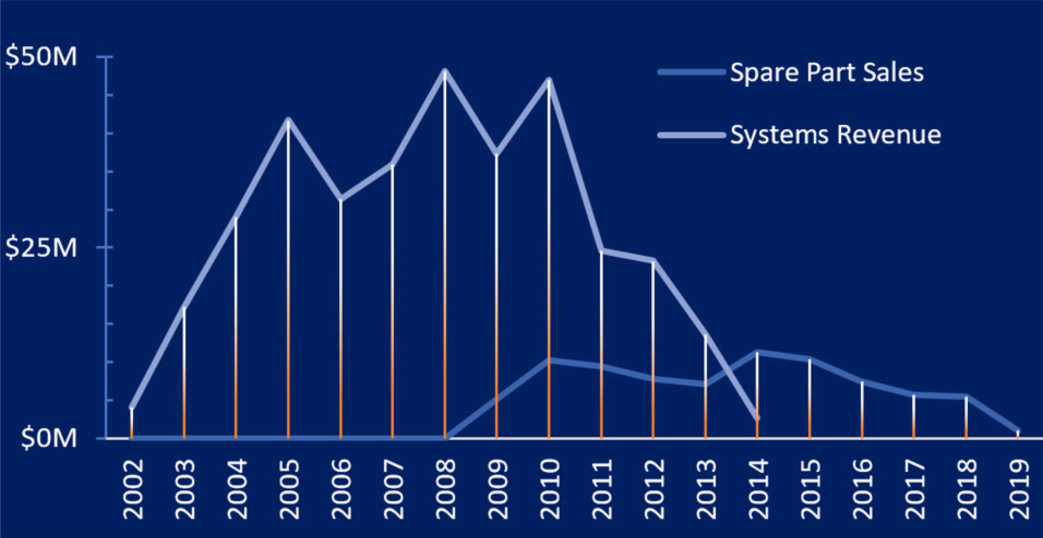

- Longest single-running customer program

- Over 500+ lab automation systems supplied

- ~$500M in sales orders over 17 years of service

- System ranged between $150k to $1.5M each

- Manufactured 50 systems/year

Extended Services:

- ATS VA/VE engineering focus

- YoY cost reduction targets

- Primary refurbishment and spare parts provider

- 10-year “Extended Life” service contract (~$40M)

- Multiple 100% on-time delivery awards

Results:

Fulfilling a Surge Demand to Complement Existing Manufacturing Systems

INDUSTRY: MEDICAL DEVICES

PRODUCT: ENDOSCOPE IMAGING SYSTEM

Program Notables:

- 75 units over 2 years

Extended Services:

- BOM reconciliation and reconstruction

- Obsolescence review and replacement

- VA/VE services

Surge demand required ATS to complement existing manufacturing while long-term capacity infrastructure was put in place. ATS was able to fulfill the one-time order while providing a valuable obsolescence review, VA/VE service, and comprehensive BOM and drawing package clean-up.

Enabling Global Reach as a North American Production Site

INDUSTRY: MEDICAL DEVICES

PRODUCT: cENTRIFUGE

Program Notables:

- Rescued manufacturing from deficient supplier not meeting GMP requirements

- Moved production to ATS Automation

- 10-15 systems per year (2019: 120 units delivered)

- CE, UL certified for worldwide distribution

Extended Services:

- Re-designed system to double speed and increase capacity by 50%

- ATS SmartVision employed to address imaging reliability concerns

Testimonial:

Before ATS and with only three units sold, focus was on major manufacturing and inhibiting quality issues. With ATS, production and quality was no longer a concern. We were able to re-focus on steady sales growth.

Results:

Ready to explore the full potential of a contract manufacturing partner?

More Case Studies

BROCHURE

Your Pharma Projects, Our Proven Automation Solutions

Are you a pharma manufacturer? Learn about how we can help you with your project

BROCHURE

Your Medtech Projects, Our Proven Automation Solutions

Are you a medical device or diagnostic manufacturer?Learn about how we can help you with your project

Fact Sheet

Standard Autoinjector Manufacturing System

Pre-engineered for lower design costs and faster delivery; suitable for any common three-piece autoinjector

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube