Simply put, smart conveyance drives productivity.

Consumers demand immediacy and in order to keep up with such demands, manufacturers must rethink their production processes. Automation cells no longer can be looked upon to produce one standardized batch or product, instead, they need to be flexible and re-deployable to create shorter cycles. For manufacturers to remain competitive, engineers are being tasked with rethinking their current processes and developing ways to not only produce more, but produce more in smaller amounts of space.

To really understand the benefits of smart conveyance and how it’s helping manufacturers achieve their goals; it’s essential to look at the limitations of traditional conveyance.

Traditional conveyors – be it roller, belt, dial, etc. – are generally synchronous, meaning each shuttle (or dial position) move together, in the same way, over and over again. There is no flexibility, every step in the process has only one option and process time is dependent on your longest station. These kinds of systems can be effective for manufacturing operations that have lower volumes or simple operations, but the problems come when you have complex processes that require greater productivity as traditional conveyance typically has longer cycle times, isn’t as flexible and can actually require a greater investment in equipment. These limitations are in contrast to the needs of modern manufacturing.

So how can you enable higher performance automation that is fast and fits into the floor space that you have available? And how can you clearly identify ROI? To answer this question we must first fully understand the limitations of traditional conveyance.

Let’s start with an example looking at a traditional conveyor:

If there are two stations, one with a cycle time of one second, the other with a cycle time of two seconds. With traditional conveyance, the shuttles will move into the stations synchronously causing the cycle time to be that of the time of the slowest station plus the time to retract stopper cylinders, locate tooling, and then index between stations.

To save cycle time, you can add a buffer station. This will allow the shuttle to index into station 2 faster because it doesn’t have to wait for locate tooling and stopper cylinders to retract, and the distance can be shorter. While this may reduce cycle time slightly because you are now adding in buffer stations, the overall footprint of your cell has increased.

Another option is to change the process from 1 up to 2 up. This means that you will be working on two parts instead of one part at a time. To implement this, you need to double up each station, and you will likely also want to include buffer shuttles. The challenge here, as you can see, is that the system has again increased in size, and because you are adding duplicate stations, it is increasing in cost.

By nature, any technology that is considered smart, must have a certain degree of inherent intelligence and capability. It must also allow the user to take advantage of such functionalities without having an advanced engineering background. Smart technologies and products also enable Industry 4.0 because they provide a means to be modular, reconfigurable, and more robust by offering integrated functionality that is tested and ready to use.

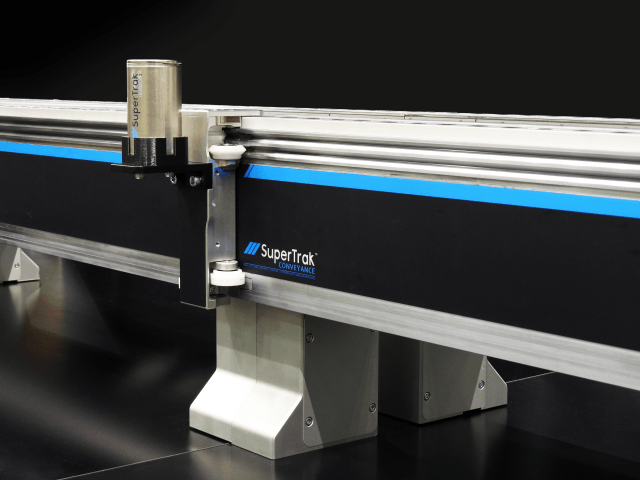

Smart Conveyance provides value by incorporating a number of features into one platform, allowing a higher level of performance and productivity than that of traditional conveyance. Generally, it is powered by linear motor technology using a moving magnet shuttle system. This means that your system is a servo, so you have independent control of all the shuttles; it’s fast and precise; and it’s incredibly flexible in terms of scalability and process flows.

Let’s look at an example of smart conveyance:

To achieve the fastest and most productive cycle time, we can use a similar system design as in our traditional conveyance example. But now, we don’t need to duplicate the 1 sec station because we now have asynchronous control of the shuttle. The flow will go from 1 up to 2up. We also no longer need the buffer space because we can take advantage of the speed and precision of Smart Conveyance. There is no locate tooling or stopper cylinders. The shuttle in station 1 moves to station 2b and 2a alternately. We now have a smaller footprint because we were able to remove a station, have decreased our cycle time and are ultimately more productive.

While smart conveyance may not be right for everyone (check out our Go-No-Go Guide video if you’re not sure if it’s right for you!), it helps modern manufacturers achieve greater productivity with a smaller footprint. The SuperTrak CONVEYANCE™ family of platforms is a leader in smart conveyance. It acts as the stable foundation for many of the world’s fortune 500 companies. With hundreds of deployments across the globe for a wide range of applications, not only is it innovative, but it’s also trusted. To learn more about smart conveyance and manufacturing productivity, contact the SuperTrak Team.