Automotive Manufacturing

High-Volume Assembly in the Timeline That Works for You

Whether you are an OEM or a tier one supplier, you need the same things - to be able to move fast and adapt to a changing market.

For over 20 years in business, we have partnered with industry leaders like you across the world, making SuperTrak CONVEYANCE™ a widely recognized and trusted name in automation.

High-Volume Assembly

We know that assembling automotive components requires high throughput, SuperTrak CONVEYANCE™ enables you to achieve your targets by providing high-speed operation (acceleration up to 4G, speeds up to 4 m/s) and precise system capability (down to +/- 0.01 mm repeatability).

Finally, industry-leading settling time means less time waiting and more time in process, increasing throughput. This results in greater automotive manufacturing efficiency.

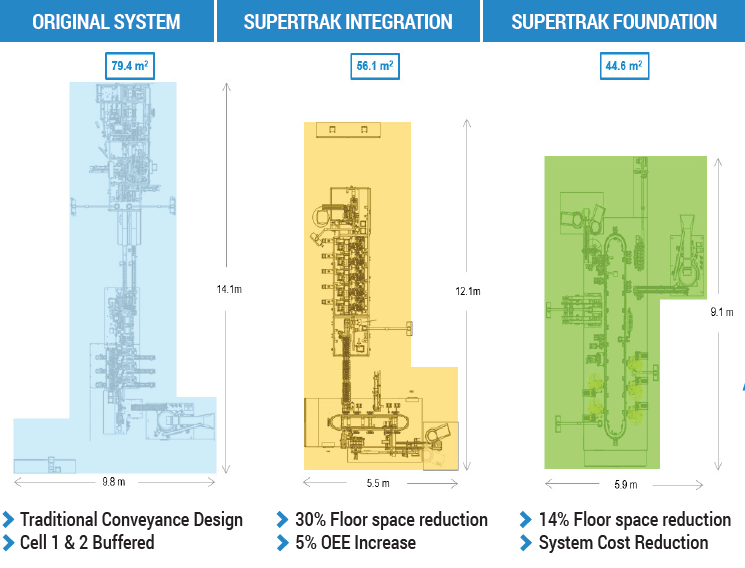

Smaller Footprint

For manufacturers, floorspace is at a premium. The amount of integrated functionality that is packed into the platform gives more performance in a compact footprint. By utilizing integrated functions, manufacturers can also eliminate redundant tooling and has the added benefit of reducing overall material costs.

Read full case study here.

Precision

Assembling automotive components requires precision. From gear placement, part insertion, function testing, electrical connections, and beyond, you need to know that your process can deliver precise, scalable solutions.

Individually controlled shuttles allow you to control the exact position on each shuttle. Stop positioning can be configured in the TrakMaster™ software anywhere, even on the curves. This allows you to create an extremely flexible process flows to increase your throughput without an increased footprint.

Harsh Environments

Productivity and uptime depend on a robust automation system that can withstand harsh or dirty environments often experienced in automotive manufacturing. With few moving parts and easy maintenance, SuperTrak CONVEYANCE™ keeps your line moving.

See more frequently asked questions here.

Resources

SuperTrak CONVEYANCE™ – Features & Applications

Real-life manufacturing applications highlight how the SuperTrak CONVEYANCE™ platform allows engineers and manufacturers the ability to overcome common manufacturing challenges related to factory footprint, scaling, market uncertainty, tight project timelines and re-deployability.

Watch VideoHow to achieve high-performance automation in a smaller footprint

Scaling your business should be easy. The success of today’s manufacturers relies on it. In addition to achieving high-performance goals, application engineers have very specific space confines they must work within to meet business objectives. These can include accommodating additional technology, working around permanent fixtures such as support columns, or even integrating a newer system …

View BlogAsk the Expert – What Environments is SuperTrak CONVEYANCE™ Best Suited For?

Join Director of Sales, Karl Ortmanns, as he discusses the many different manufacturing environments in which a SuperTrak™ can operate in Episode 4 of our Ask the Expert series!

Watch Video