Smart Conveyance makes manufacturing more efficient by leveraging asynchronous motion. A basic definition of “asynchronous motion” is, “a process that allows final execution with multiple separate tasks being performed in a concurrent, yet staggered, way so that one step of the process can be started even before the prior task is complete.”

When it comes to conveyance, traditional forms of conveyance such as indexing conveyors or indexing dials typically provide synchronous motion, meaning each station operates at the same time in the same way. There is no flexibility; every step in the process has only one option and process time is dependent on your longest station’s duration. With traditional conveyance, a product or piece moves from station to station, and for simple processes, this format may be sufficient. Smart Conveyance, on the other hand, leverages asynchronous motion to allow system designers to only duplicate stations where they are needed, which helps machine builders maintain ideal throughput. Smart Conveyance provides significant value to machine builders and end users as it reduces the quantity of stations and tooling while allowing for maximum utilization of every station. While most conveyance systems are passive – simply just moving parts from A to B – Smart Conveyance makes motion active, positively impacting the process itself. This typically means that overall, there is a reduction in the complexity and cost of an automation system.

The key features of Smart Conveyance are:

- High speeds

- Greater precision

- Independent shuttle control

Increased Manufacturing Efficiency

Applying Asynchronous Motion

The asynchronous motion that goes hand-in-hand with Smart Conveyance is beneficial as it allows systems to move between single-up and multi-up processes. This capability allows for the removal of redundant stations and eliminates buffer zones so cycle time is no longer limited by the slowest station. Asynchronous motion improves manufacturing efficiency threefold: it improves cycle time, reduces redundant tooling, and reduces the factory footprint of your automation solution.

Less Tooling Required

Traditional conveyance relies on external tooling (stopper cylinders) to stop a shuttle, Locate tooling to position, and hold it in place while the tooling does its job. This takes time, programming effort, and requires additional parts, which means more parts that require maintenance down the road.

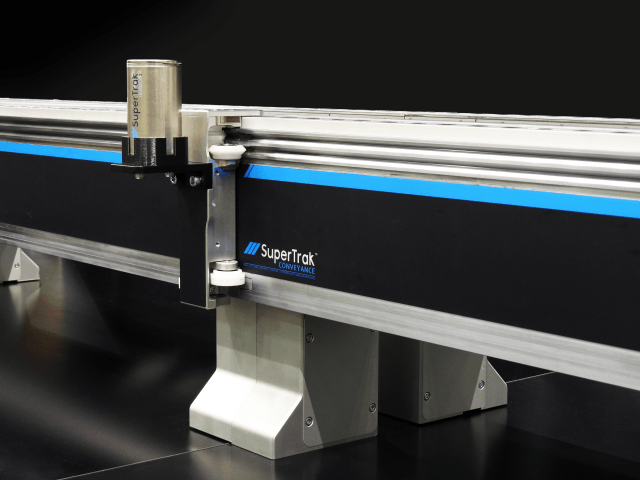

Smart Conveyance moves shuttles into the station with speed and accuracy without stopper cylinders. It’s powered by servo precision so shuttles are able to stop, and operations can commence immediately.

Improved Operations

Cycle time is at the heart of every automation solution. Sometimes tooling is overworked trying to keep up with cycle time requirements. While a quick cycle time seems beneficial in the short term, the long-term impact of this could be system crashes or incorrect processing of the product, thus lowering the quality of the finished product. With the high-speed, precision, and independent shuttle control offered by Smart Conveyance, other parts of the system don’t have to work as hard. This can produce higher yields and lower failure rates.

Reduced Downtime

Downtime can be detrimental to a business’s throughput. With traditional conveyance, downtime typically requires human interaction to not only move shuttles, retract stopper cylinders, and locate tooling, but it also requires the manual recovery of putting everything back into place. With Smart Conveyance, after downtime, shuttles automatically recover to their last position – reducing the need for skilled workers to get the system running again. This means your automation solution can get back to work faster and with less complex programming.

Unlocked Energy Savings

Acceleration and velocity can be modified with asynchronous motion, which can help you optimize your automation system’s energy consumption. Through simulation and Smart Conveyance, energy consumption can be minimized without impacting productivity.

When indexing motion and changing between single-up and multi-up processing, you can reduce duplicate stations because of asynchronous capability. As mentioned earlier, this not only reduces your factory footprint, but also reduces energy consumption by eliminating the need for additional tooling.

Decreased Design Complexity and Engineering Hours

One major benefit of Smart Conveyance solutions, like SuperTrak HORIZON10™ , is the integrated functionality it offers. Unlike other forms of conveyance, all this functionality is incorporated into one platform which reduces system complexity and, the time and effort needed to integrate and deploy a system. This means manufacturers can get to market faster!

A sample of SuperTrak HORIZON10™ integrated functionality capabilities include:

- Collision avoidance

- Target routing

- Pre-stops

- Defined regions for specific motion dynamics

Is Smart Conveyance Right for My Application?

Smart Conveyance isn’t a blanket solution for everyone within the automation industry. While it can reduce the cost of high-performance automation, there are certain criteria that should be identified for companies to realize value with Smart Conveyance. As part of the discovery phase at SuperTrak CONVEYANCE™, we utilize a Go-No-Go Guide to help highlight applications that may benefit from a Smart Conveyance solution. The Go-No-Go Guide looks at major and minor identifiers to determine if value will outweigh cost for a Smart Conveyance solution. A general rule of thumb indicates that if an application has at least two major and two minor identifiers, Smart Conveyance is a good fit. Watch the video below to learn more.

Major identifiers used to assess applications:

- Six or more process steps

- Cycle times of eight seconds or less

- +/- 0.1 mm precision

Minor identifiers may include:

- Payload weights of 10kg or less

- Scalability requirements

- Multi SKU production needs

- Floorspace limitations

- Energy reduction

- Operation noise levels

- Cleanliness requirements

The SuperTrak CONVEYANCE™ Advantage

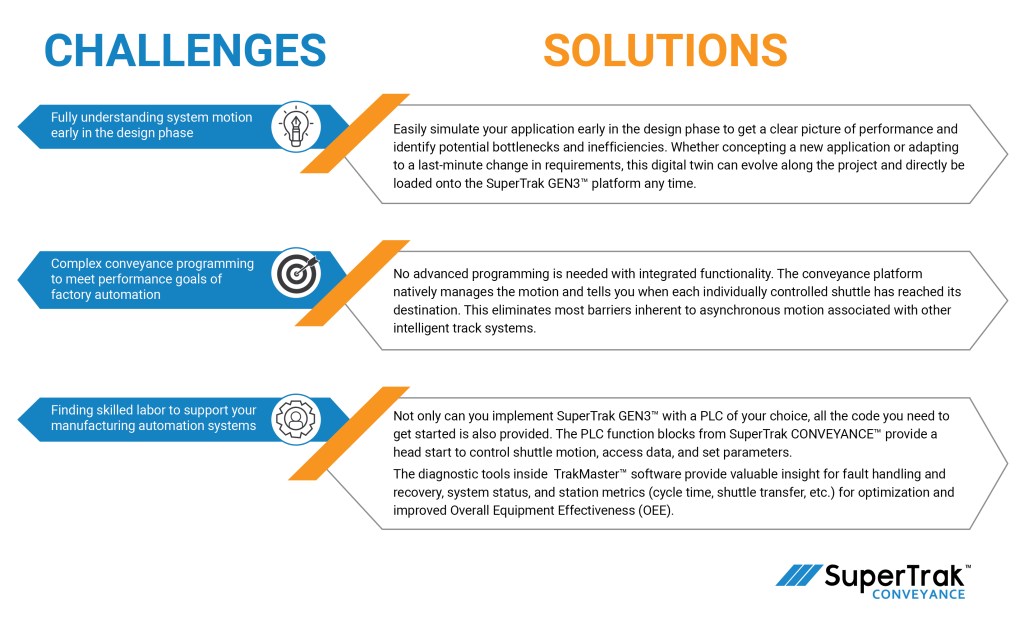

Designing and implementing an asynchronous automation system can be challenging for several reasons. Typically, these systems are very complex in nature and you, as engineers and designers, need to accurately understand your motion at an early stage to fully optimize your design and get the best ROI from your system. In order to reduce the margin for error in design, the conveyance platform should intuitively be able to coordinate the motion throughout the process without complex programming. Finally, with the skilled labor shortage continuing to be an issue for manufacturers, integrating and operating factory automation can be difficult.

Here’s where the SuperTrak HORIZON10™ can set you apart from your competitor without sacrificing on performance or quality.

Unlike other forms of conveyance, the speed, precision, and independent shuttle control provided by SuperTrak CONVEYANCE™ are all features to help you increase your manufacturing efficiency with Smart Conveyance. Offering a +/- 10mm repeatability feature means that stopper cylinders and locate tooling may not even be required, yet still allows for high quality standards, high throughput, and a smaller factory footprint.

What makes this possible? TrakMaster™ software is the user interface for the SuperTrak HORIZON10™ platform and empowers an intuitive PLC interface to control the SuperTrak™ platform’s high-performance capability with less engineering and, therefore, less risk. It combines simulation, configuration, and diagnostic tools into one package that provides machine builders and manufacturers a faster path to production.

Smart Conveyance: Challenges and Solutions

Your conveyance platform impacts nearly every component in your automation system and should be considered early in the design phase to optimize system performance and OEE. If you’ve determined that Smart Conveyance is a good application fit, download our Design Starter Kit to understand how to create an effective system design using the SuperTrak HORIZON10™ platform. To learn more about Smart Conveyance or to determine if your future applications may be a fit, contact our team of experts today.