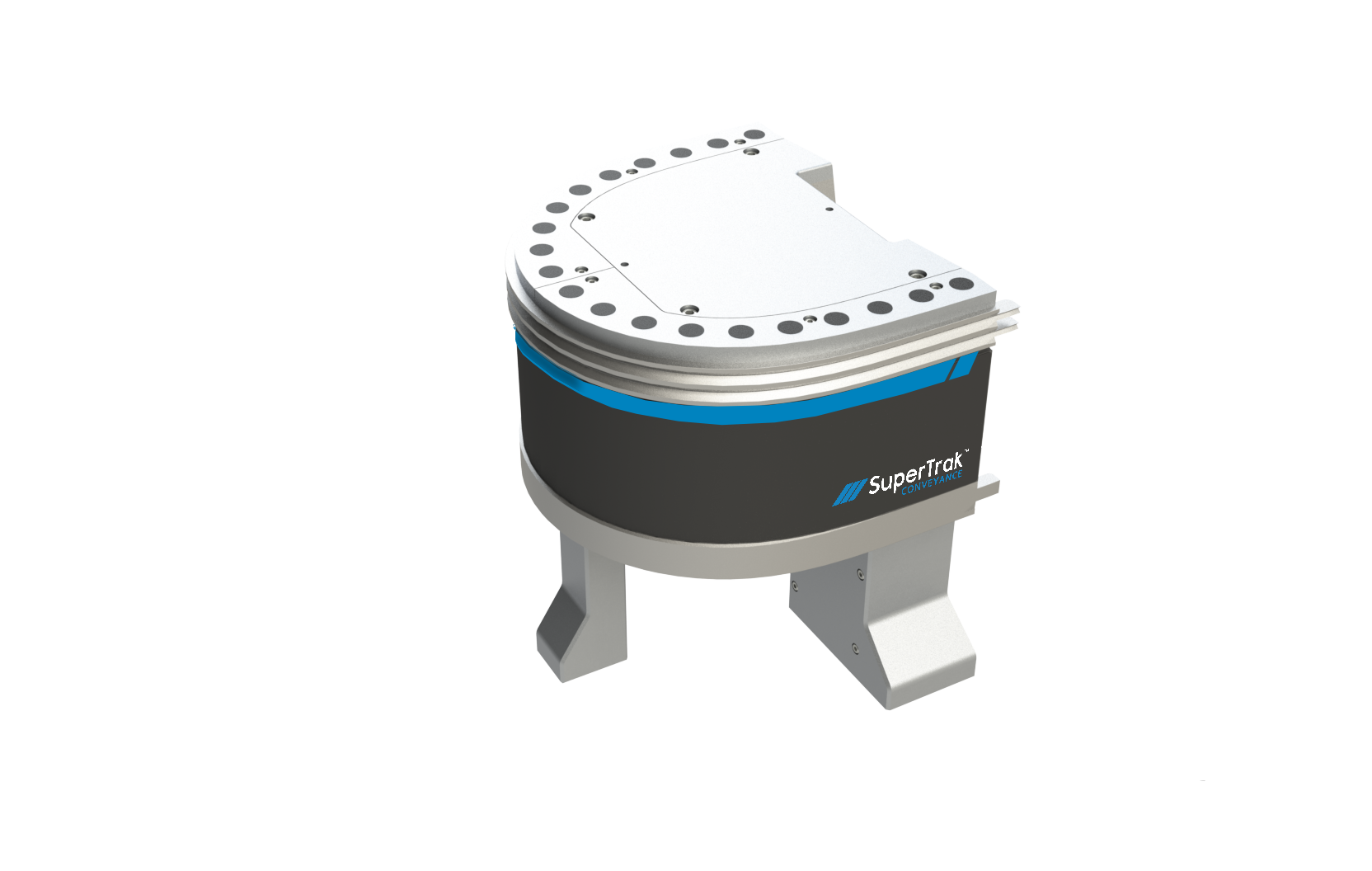

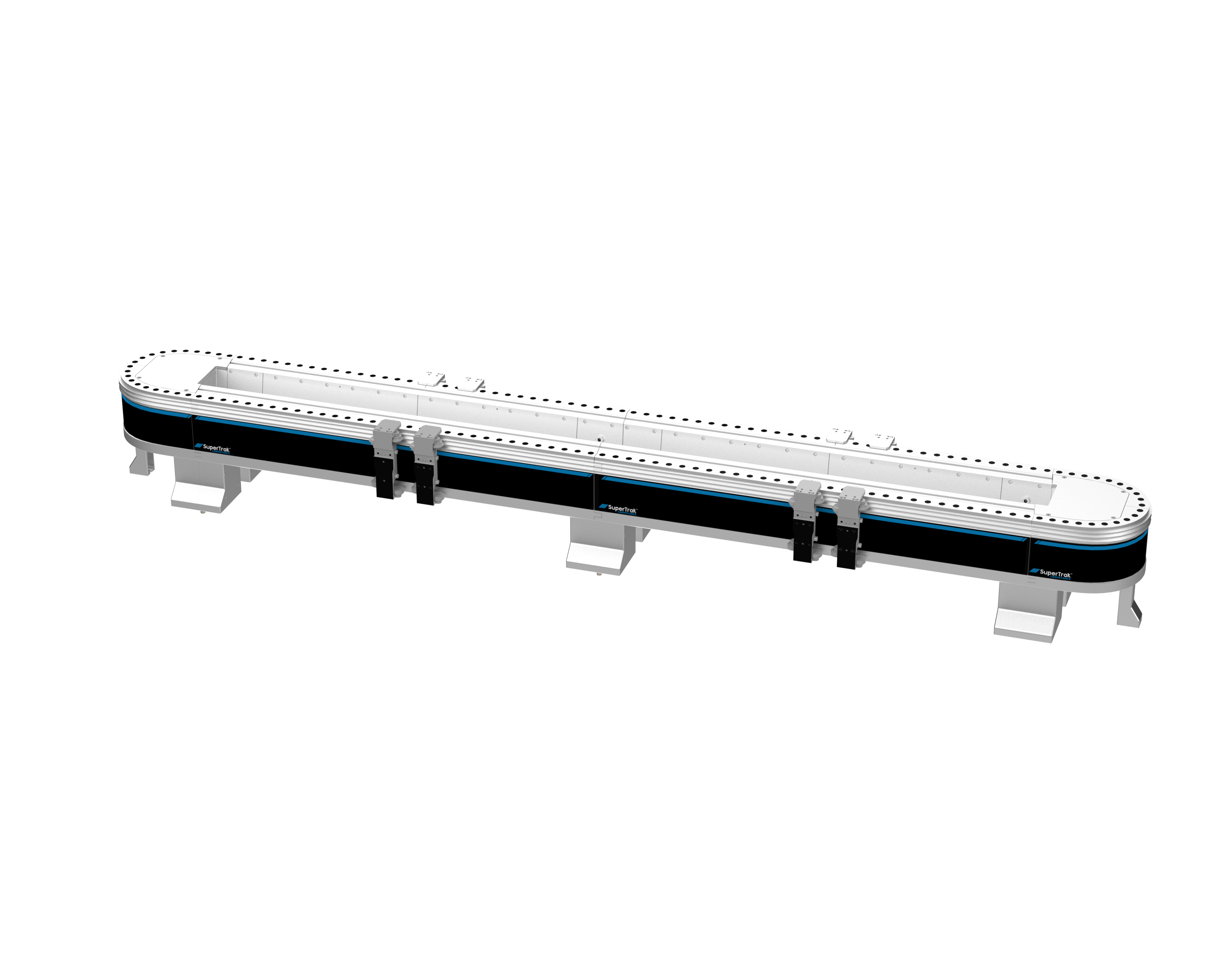

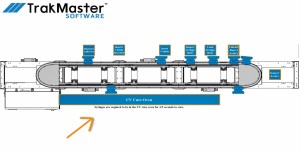

SuperTrak GEN3™ – 90° Configuration

The new 90° configuration offers the same floor saving space as a servo or indexing dial. The 90° curved sections allow for even more configuration options such as a squared circle or rectangle. When using this configuration, the system can grow in both length and width. Two 90° sections back to back allow for a system that is 1200mm wide. Manufacturers can fit even more tooling on the inside to minimize system footprint.