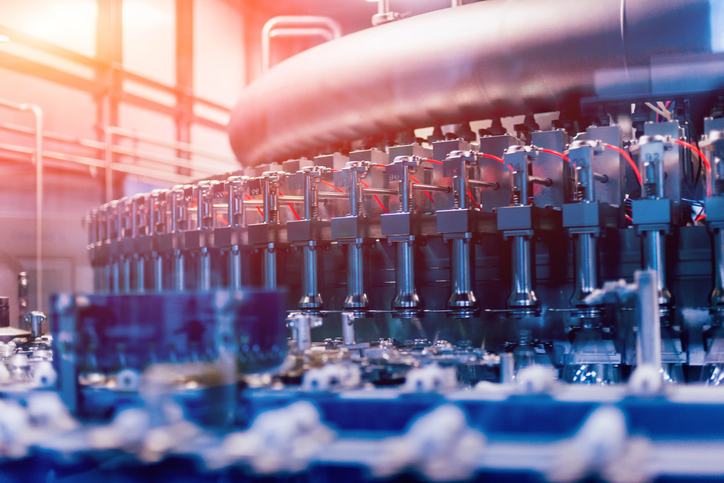

SuperTrak CONVEYANCE™ – Features & Applications

Real-life manufacturing applications highlight how the SuperTrak CONVEYANCE™ platform allows engineers and manufacturers the ability to overcome common manufacturing challenges related to factory footprint, scaling, market uncertainty, tight project timelines and re-deployability.

Watch Video