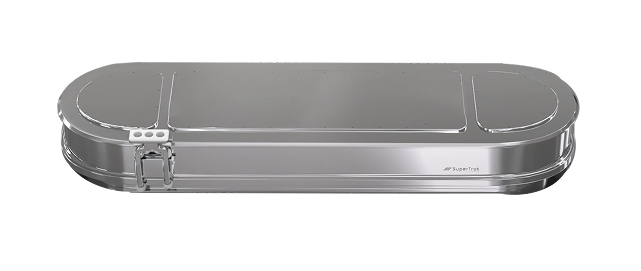

SuperTrak PHARMA8™ is a magnetic conveyor designed for Grade A aseptic environments

The independent shuttle control of SuperTrak PHARMA8™, combined with up to 30m/s² acceleration and +/-0.01mm repeatability, allows machine builders to reduce repetitive tooling and decrease the size of the isolator.

SuperTrak PHARMA8™ is the new standard for aseptic processing

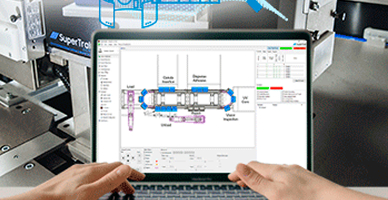

Machine builders and manufacturers can design, develop, and deploy fill/finish automation solutions while reducing engineering complexities and risks without sacrificing performance.

Specifications, Components and Configurations

Designed to meet FDA and EMA requirements, SuperTrak PHARMA8™ has stainless steel outer surfaces and hermetic seals suitable for Grade A spaces and is ideal for life science and pharmaceutical manufacturing.

Independent Shuttle Control

Independent Shuttle Control

Each shuttle’s properties can be controlled independently.

Speed: up to 4 m/s

Speed: up to 4 m/s

Improved speed and less time spent in motion.

Precision: +/- 0.01 mm repeatability

Precision: +/- 0.01 mm repeatability

Fewer add-ons needed, leading to shorter cycle times.

SuperTrak PHARMA8™ makes operations simpler

This magnetic conveyor owes its proven reliability to its unique design, including limited moving parts and a shuttle that can be removed or replaced within 60s. Automation in aseptic environments can now be leaner thanks to SuperTrak PHARMA8™.

A Smaller Size for Aseptic Environments

Compact Performance

Integrated functionalities enable more performance in a more compact machine

Efficient Indexing

Index shuttles quickly to eliminate the number of tooling parts required

Optimized Throughput

Increase throughput using the system’s repeatability to remove stopper cylinders and locate tooling

Integrated Functionality

The SuperTrak CONVEYANCE™ platform is a Smart Conveyance technology that provides value by incorporating several features into one platform.

Integrated functionality means less complexity and less automation tooling, allowing for faster market time.

A sample of integrated functionality includes:

- Collision Avoidance.

- Target Routing.

- Pre-stops.

- Define regions for specific motion dynamics.

Industry Applications

Based on over 25 years’ experience deploying Smart Conveyance solutions, SuperTrak PHARMA8™ is setting the new standard for aseptic processing.

Fill and finish

Precise batch control with easily cleanable surfaces for wipe down and vaporized hydrogen peroxide that will meet FDA isolator requirements.

Testing and development

Useful for double barrel-injector applications where recirculation of parts is needed, or various batches are being run.

Benefits

Explore other products

Start a new Project & Get a quote

Increased precision means leaner automation as it reduces:

- the amount of stop and locate tooling

- the required engineering effort

- the burden on operations to maintain complex tooling

Use SuperTrak CONVEYANCE™ high precision and low settling time to simplify the design and operations of the final assembly machine.