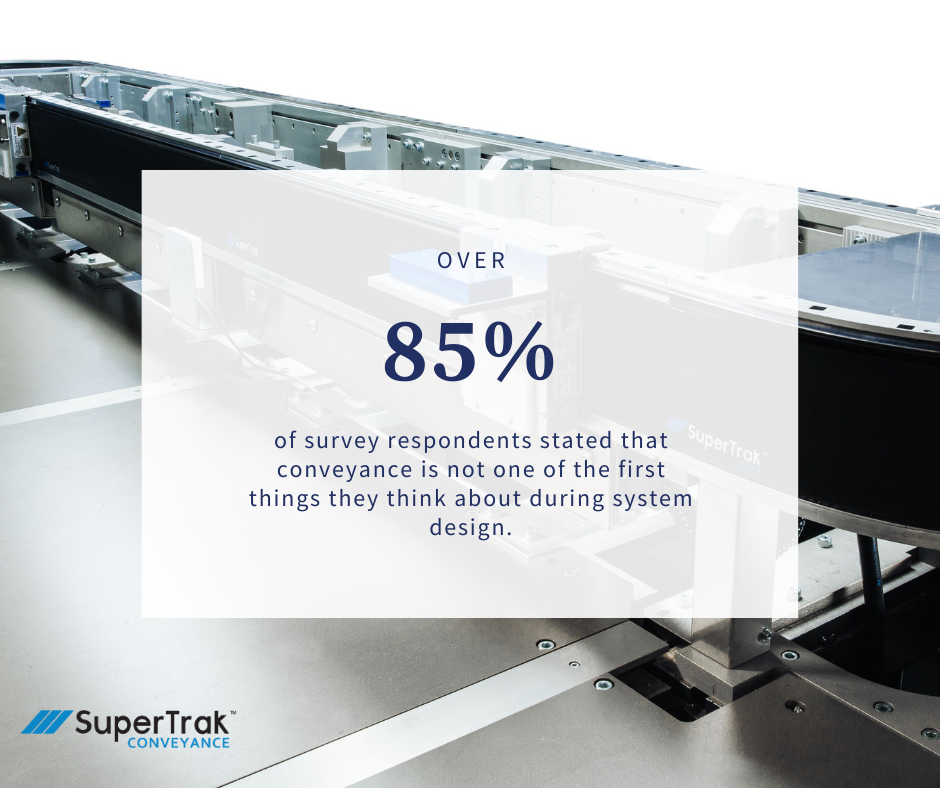

Did you know that 85% of designers don’t consider their conveyance platform – or how they are going to move a part from station to station – during the first phases of their design process?

The SuperTrak team recently did a survey asking industrial automation professionals when they think about their conveyance platform while designing their automation that generated some interesting insights.

Some of the answers we received were:

- Later – individual station function would be more important initially

- Conveyance is secondary and is selected to meet the needs of the process serviced by that conveyance

- Need to understand independent processes and how they relate to each other before choosing a conveyance method

- Later in the process – we started off with a simple solution and left it open to improve later

- The takeaway is that conveyance is not the first thing that people are thinking about during system design.

Interestingly, when we asked this same question to our in-house engineers who are responsible for designing complete automation systems across a number of industries, we got a much different answer – the answer we predominantly received from them was that conveyance was a starting point in their system design.

So this got us thinking, what could account for this discrepancy?

Digging Deep

After some digging and talking more in-depth to our engineers and survey respondents, it became apparent that our in-house team is working closely with the SuperTrak platform almost daily. They had gained an in-depth understanding of the functionality of a smart conveyance platform and how it could impact their overall system design. Whereas others who weren’t as familiar with the technology or worked with different forms of conveyance in the past hadn’t necessarily experienced or weren’t aware of the value that a smart conveyance technology can offer.

Well….we’re about to change that!

Our primary objective has always been and will continue to be, helping our customers realize the value that smart conveyance can bring them and how it can ultimately enable them to build and deploy, better, higher-performing automation.

When we shift the conversation and bring a focus to conveyance or what we like to refer to as the foundation of your automation, we ultimately see a transformation in the way the entire automation system is built and the way it performs. This in turn has significant implications on the overall business.

During the webinar, “Is Conveyance Gating Your Growth,” SuperTrak CONVEYANCE™ GM, Simon Drexler, talks more about how when you think conveyance in the early stages of system design it can be an enabler in effectively scaling your business.

Industrial System Design

Let’s look a little closer at the design of your system.

In its most basic sense, conveyance can be defined as the movement of products from one location to another. During your automation system design, conveyance is one of many elements, but as our survey showed, designers often look at destinations first. They look at what they need to do at each process stop first, then determine how to move the “widget” from station to station.

While you’re not alone in this thought process, the end result can sometimes have undesired outcomes. These undesirable outcomes can look like cycle times that take longer than necessary, a larger factory footprint than you can afford, or an increased need for manual labour. The system you design may achieve the outcome you created it for but when conveyance isn’t considered during the design phase, it can have unintended consequences.

Beyond Industrial System Design

As you can see above, your conveyance platform impacts nearly every aspect of your automation system. From cycle times to required maintenance, to required tooling, your conveyance platform impacts the design and performance more than any singular

component of your automation cell.

This means it has a significant impact on your:

- People

- Process

- Infrastructure

In order to achieve the goals you set out for your business, you must have a plan or strategy in place which takes into consideration all of these elements. Since your conveyance impacts or touches every element of your strategy (people, process, infrastructure), this is typically a good starting point.

Let me explain.

People: The technology you choose will have a direct impact on how many labourers you need and the skill set they will require to design, install and operate your equipment.

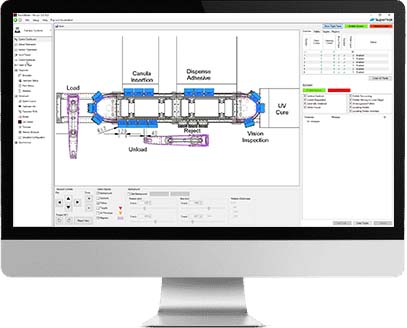

Process: Conveyance defines the system flow and directly affects the simplicity or complexity of the process changes. It can also act as the conduit to collect information about the overall system status and the parts being produced in order to improve bottlenecks and inefficiencies.

Infrastructure: Once you understand the motion capabilities (speed, direction, velocity, etc) of your conveyance, you can more accurately determine what needs to be built on top of it. This will also help determine the shape, size and overall footprint of your system.

How it impacts your people

You can easily see that there are differences in the technologies that are needed based on the conveyance selected in order to achieve similar outcomes. This means that there will be a difference in the skill sets needed and different training requirements for operators. Because there are different technologies, there will be different spare parts and maintenance schedules required. Your choice in conveyance has now impacted your people.

How it impacts your process

The conveyance platform will also impact the components within the system, which will drive differences in the process as well. How quickly we can produce components and at what quality level are significantly impacted by the technology we include in the system.

Something simple, like how fast the conveyance system can move will change what other technologies are available for the application.

How it impacts your infrastructure

Again looking at the example above, if we look at the infrastructure investment because the system and technology choices are different, they will have different levels of CapEx required, as well as a different amount of required floor space.

The foundation of your automation, also known as your conveyance platform, has a ripple effect on the rest of your automation cell, your tooling, the speed or cycle times, the space or footprint requirements on the factory floor, and the list goes on. Looking back to our survey, we too often see companies underestimate the impact that their conveyance can have on overall system design and how it can impact larger business decisions and the ability to achieve their goals.

The fact that SuperTrak is easily redeployable is also playing a significant role in the decision-making process for manufacturers. Now more than ever, the ability to adapt to uncertain market conditions is highlighted by constantly evolving customer demands and success depends on your ability to quickly and easily adapt your processes. We talk more about this in the webinar, Automation Under Uncertainty.

By focusing on your conveyance early in the design phase, you transform the way your automation systems are built, making it easier to not only design but also develop and deploy.

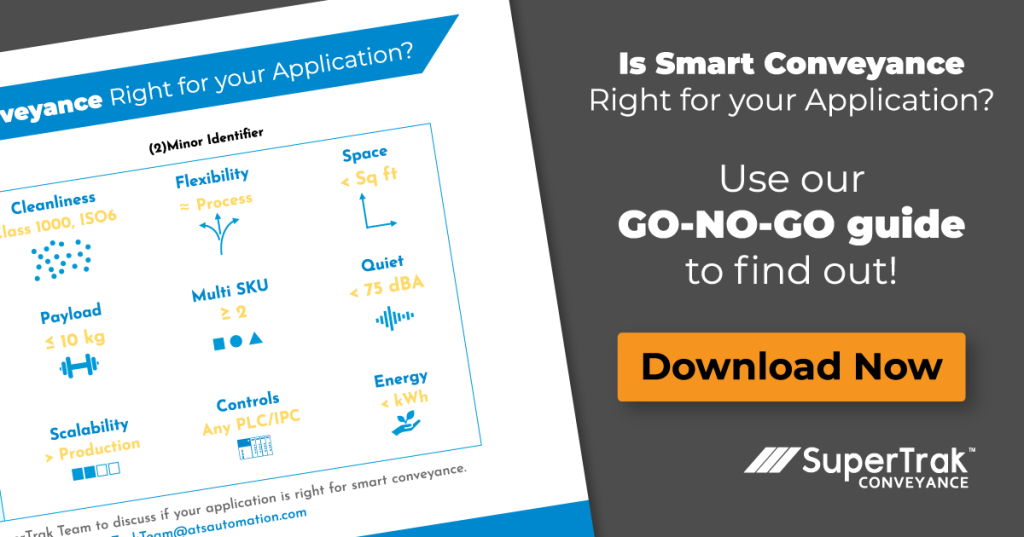

Now that you’re thinking about your conveyance, it’s time to pick the option that’s best for your application. Check out our blog, “The Right Applications for Smart Conveyance” to learn more and access the go-no-go guide we use with customers to determine if SuperTrak CONVEYANCE™ is a fit for their application.