Our engineers develop customized as well as standard solutions based on our tried and trusted platforms for any process step that you might need – ranging from pre-assembly to final assembly. We offer semi-automatic to fully automatic systems tailored to your specific requirements.

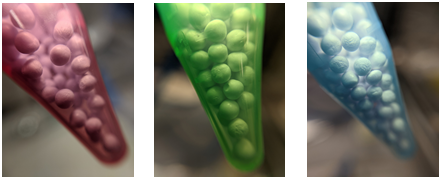

- High speed, non-contact dispensers for 2µL-30µL single drops, and nitrogen baths or cryo plates for freezing the drops

- Lyophilizers for freeze drying formed and frozen beads

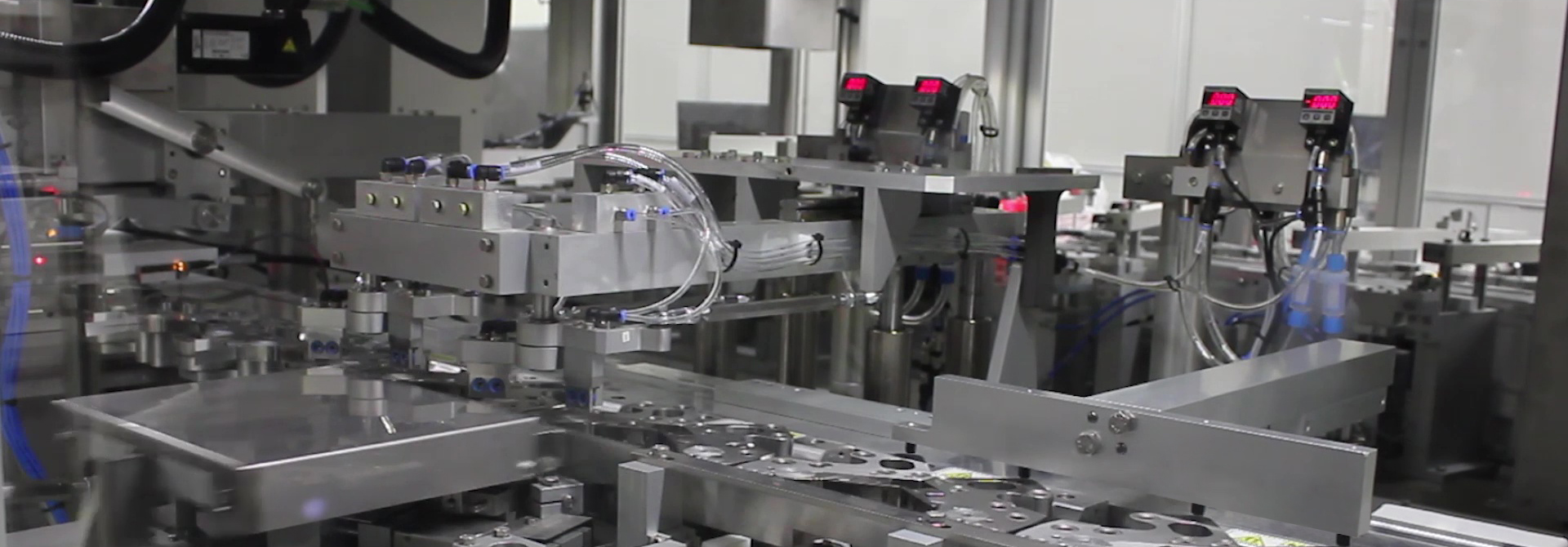

- Automation solutions for handling lyobeads; for filling into containers or assembling into diagnostic tests

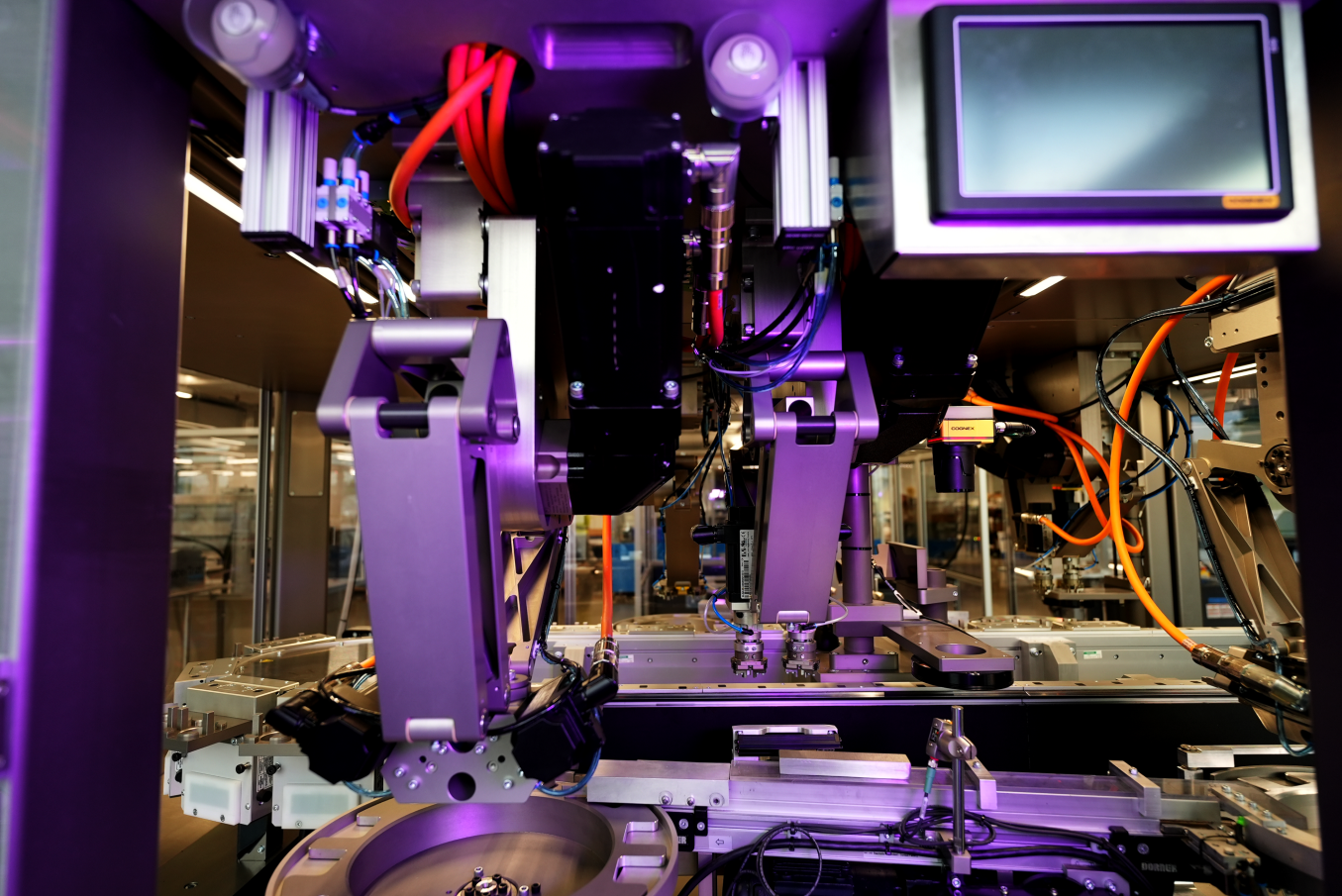

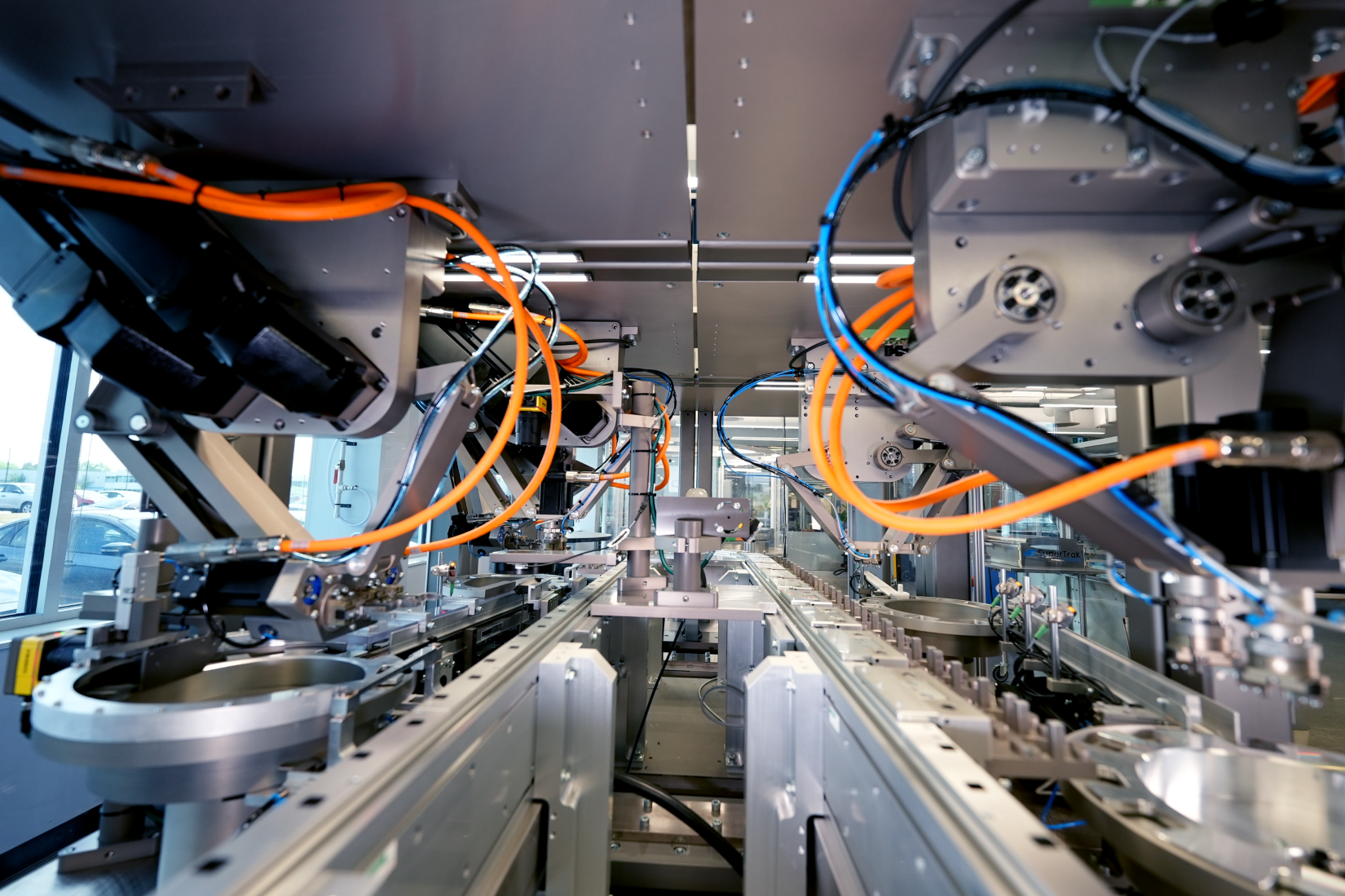

- Integrated Digital Assembly Platform

- High flexibility of pallets & robots with high speed of continuous motions

- Synchronous motions offer gentle parts handling and high precision

- 85% Standardized and modular offering scalability from R&D to full production

- 90% less tooling than conventional equipment; offers smaller footprint and lower maintenance costs

- High unit of productive capacity of equipment and floor space

- 98% MOEE at SAT