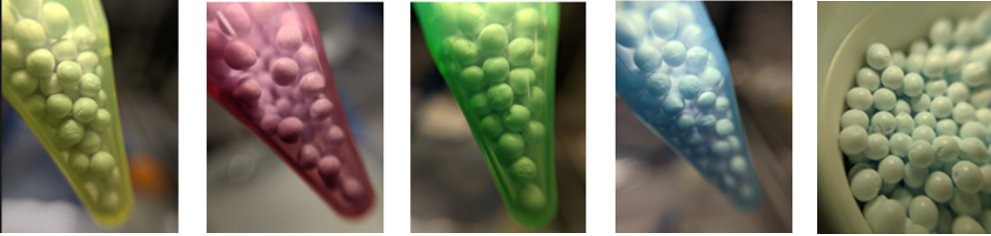

Lyophilized beads, or lyobeads, are an excellent alternative to the more traditional freeze-dried cakes. They offer thermal stability, long-term storage, and logistical benefits. Explore our lyobead manufacturing equipment.

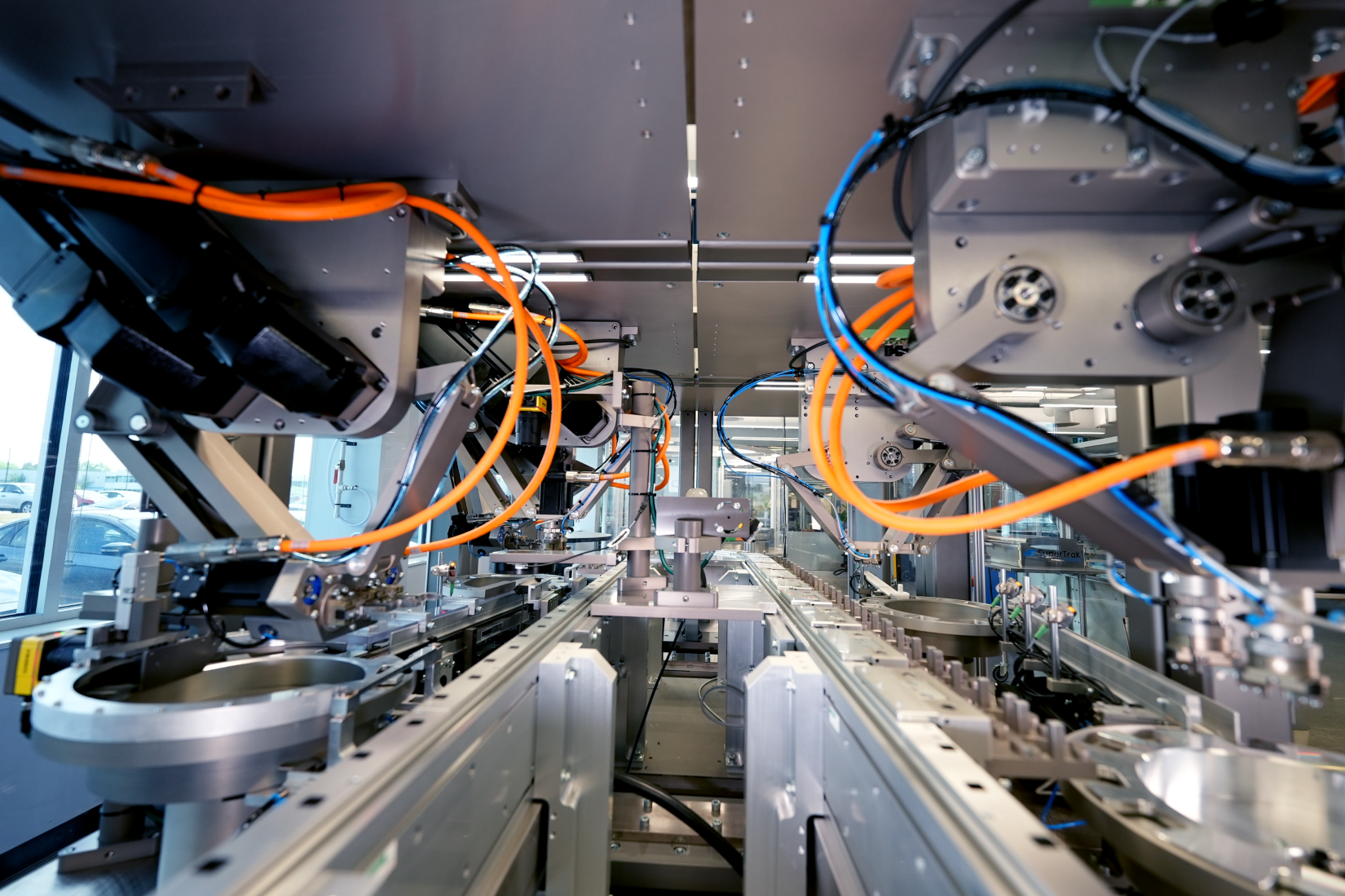

The lyobead manufacturing process begins with bead creation – the dispensing and freezing of liquid, reagent, or drug using technologies that deliver singulated beads of the desired size and shape. Secondary processes may include adding colorants or coatings, quality inspections, and more. Beads are then introduced to the freeze drier resulting in the final lyobead. And from there, the beads can be bulk packed for further processing, dispensed per recipe either uniquely or with other beads into vials or other final containers, or picked and placed into medical diagnostic cartridges or lab-on-chip products. ATS has the equipment necessary to manufacture your lyobead products.

- Industry leaders in the fields of liquid dispensing; freeze drying; material handling, assembly, and manufacturing; labelling and packaging; and integration

- Inspection capabilities with technologies like ATS SmartVision™

- Controls platform options like Rockwell or Siemens

- Data management by Illuminate™ Manufacturing Intelligence

- Global services offerings including spare parts, training, maintenance, retrofits, and relocations

- ATS Life Sciences automation solutions for gentle handling of bulk and individual beads to protect bead geometry, strength and purity

- Humidity control environments

- Cleanroom environment as required

- Unique machines for: bead filling into vials, bead placement into diagnostic cartridges or lab-on-chip, kit assembly and more