Do your suppliers include project management expertise when preparing your proposal?

Buying custom automation equipment can be a time-consuming activity that requires extensive planning for both cost and schedule. Often these plans are tied to business needs and impact decision-making for your company at a high level, so their accuracy is critical. Equally as critical is choosing the right partner to help realize these plans, ideally one that understands both your organization and the project. ATS has seen this opportunity to improve upfront planning and has integrated project management into the early phases of each program to ensure that the needs and expectations of our customers are met.

Why is project management involvement in sales important?

Both customers and suppliers want nothing more than to have a smooth, issue-free project; the unfortunate reality is that every project has unique challenges that must be overcome. These obstacles are often more frequent when dealing with either new equipment/product or a new supplier; however, they can be minimized or completely mitigated. ATS has taken a two-pronged approach to minimize these issues. The first is to include project managers in the proposal creation process prior to submitting it to a customer. The second is tied to Pre-Automation Services (PAS) where a project manager is involved more closely with the customer to understand the product, process, project and customer needs at a much deeper level.

ATS recognizes that bringing a new product to market is challenging and that even getting it to the point of discussing automation equipment can often take years of effort. We strive to improve our customer’s experience throughout the life cycle of the project and have learned that in order to achieve this we must go right back to the front end of the business, or sales. It is for that reason that all projects are reviewed by the project management team prior to submitting a bid. The project manager’s input is focused on review of the project schedule, input to risk management, and a preliminary look into the customer requirements and specifications. This forward-thinking approach to project management results in accurate picture of scope, cost, risk, and schedule. Of course, the challenges of planning for equipment delivery vary based on your customer’s experience with automation. For the newer-to-automation customers that are early in the life cycle of a product, ATS will often recommend going through PAS. The purpose of PAS is to allow you a deeper look into the process of getting equipment from PO to site acceptance testing, but more importantly enables ATS to understand the customer’s needs. It is through this process that project management can have an even larger impact and allows for the bridging of any gaps that may exist at either company. This support can be critical as the project lifecycle at both supplier and customer often have evolving team members with narrower scopes. The unification of these groups from start to finish has proven successful in assuring the goals of the project are defined and the schedule maintained.

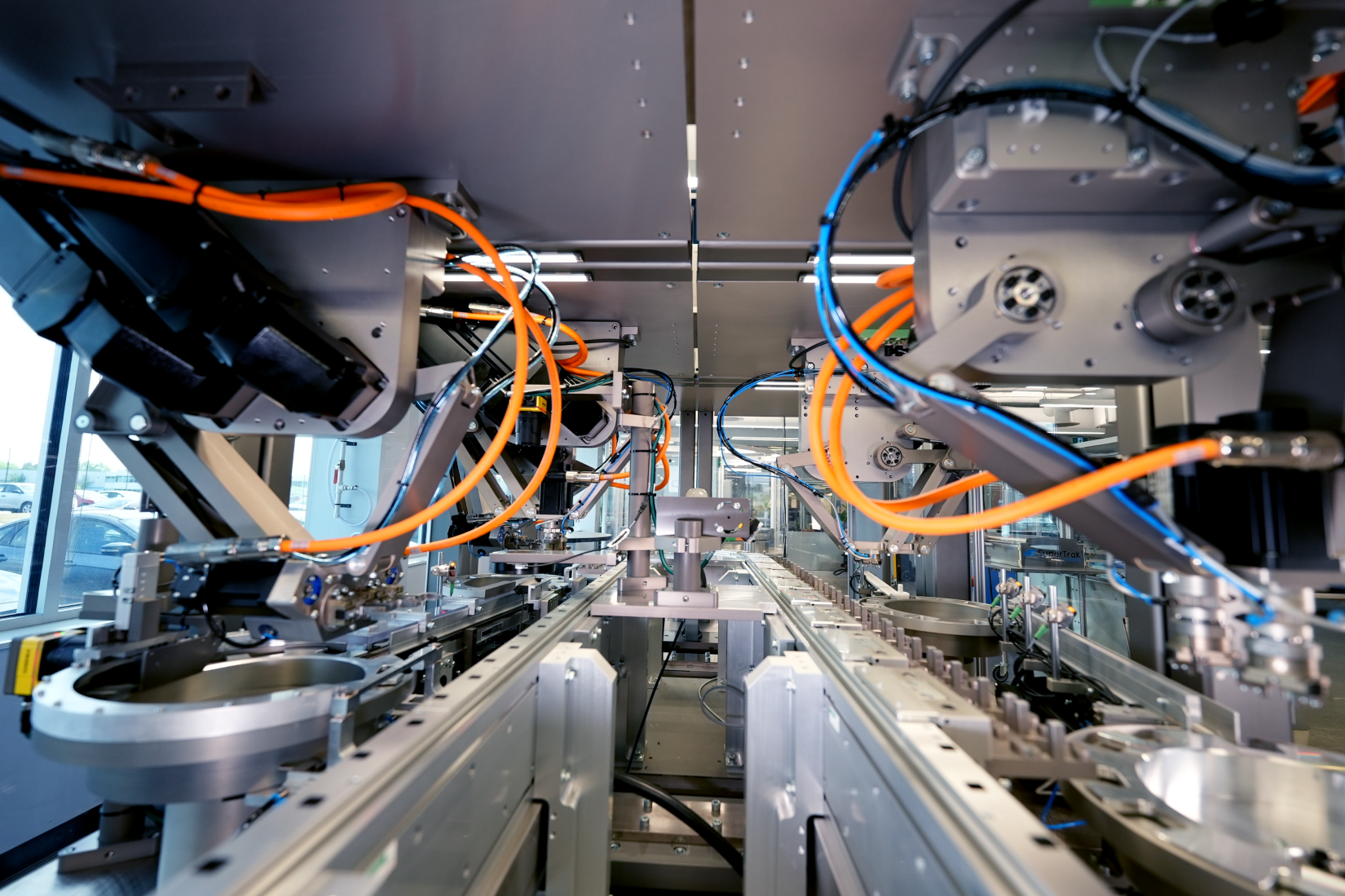

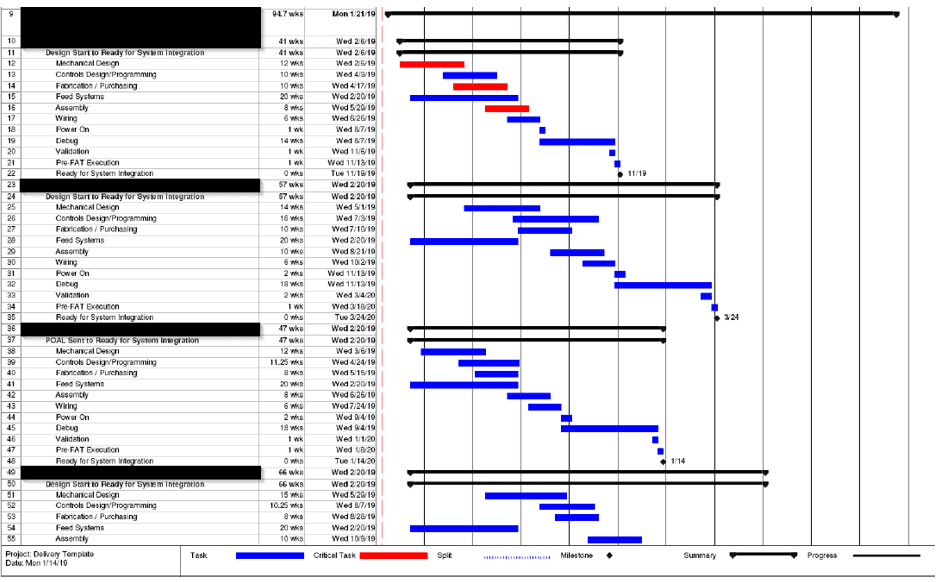

A few examples of project management input into the process early can be seen below. Image 1 shows a portion of a detailed schedule laid out during the sales phase by ATS’ project management team. This schedule was developed with input from the entire organization allowing resources to be defined early.

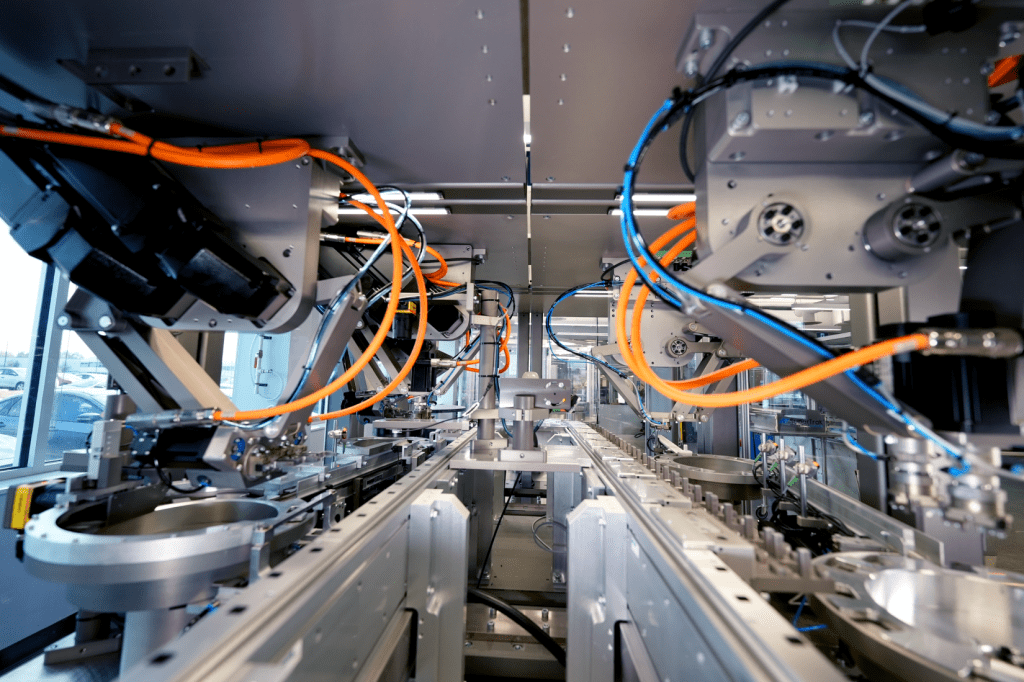

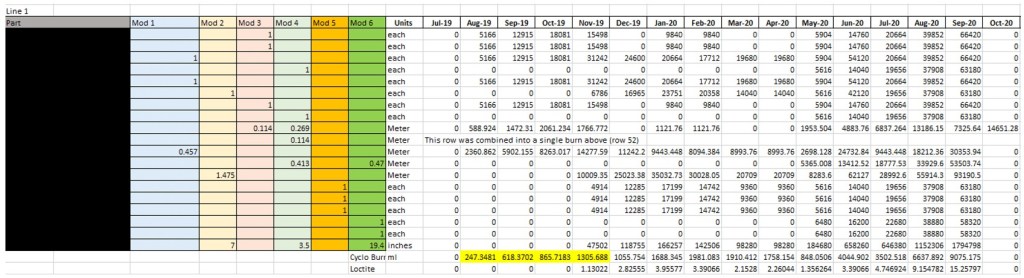

Image 2 shows a breakdown of material consumption requirements put together well in advance of PO’s being placed. Notably this specific example allowed the customer time to have raw material suppliers brought up to production requirements for material, which mitigated delays in schedule due to raw material availability.

For all projects the one constant is time, and industry as a whole is moving to more aggressive schedules. ATS takes a proactive approach to realize these schedules by incorporating more upfront planning and getting project management involved early. However, the degree of involvement is based on getting the automation supplier involved early in the process. There are 2 options our customers can utilize to realize their schedule requirements, either engaging with a PAS offering or reaching out with opportunities earlier. Preliminary investigations and early talks with suppliers can and have shown drastic improvements in the execution of projects.

The result of these efforts is a smoother project with better customer relations from start to finish. Aligning expectations early for projects of all sizes drives more accurate planning from both sides and streamlines the delivery process, effectively mitigating any disconnects between the sales activities and the execution activities.

Contact us to learn more about delivering customized automation equipment.