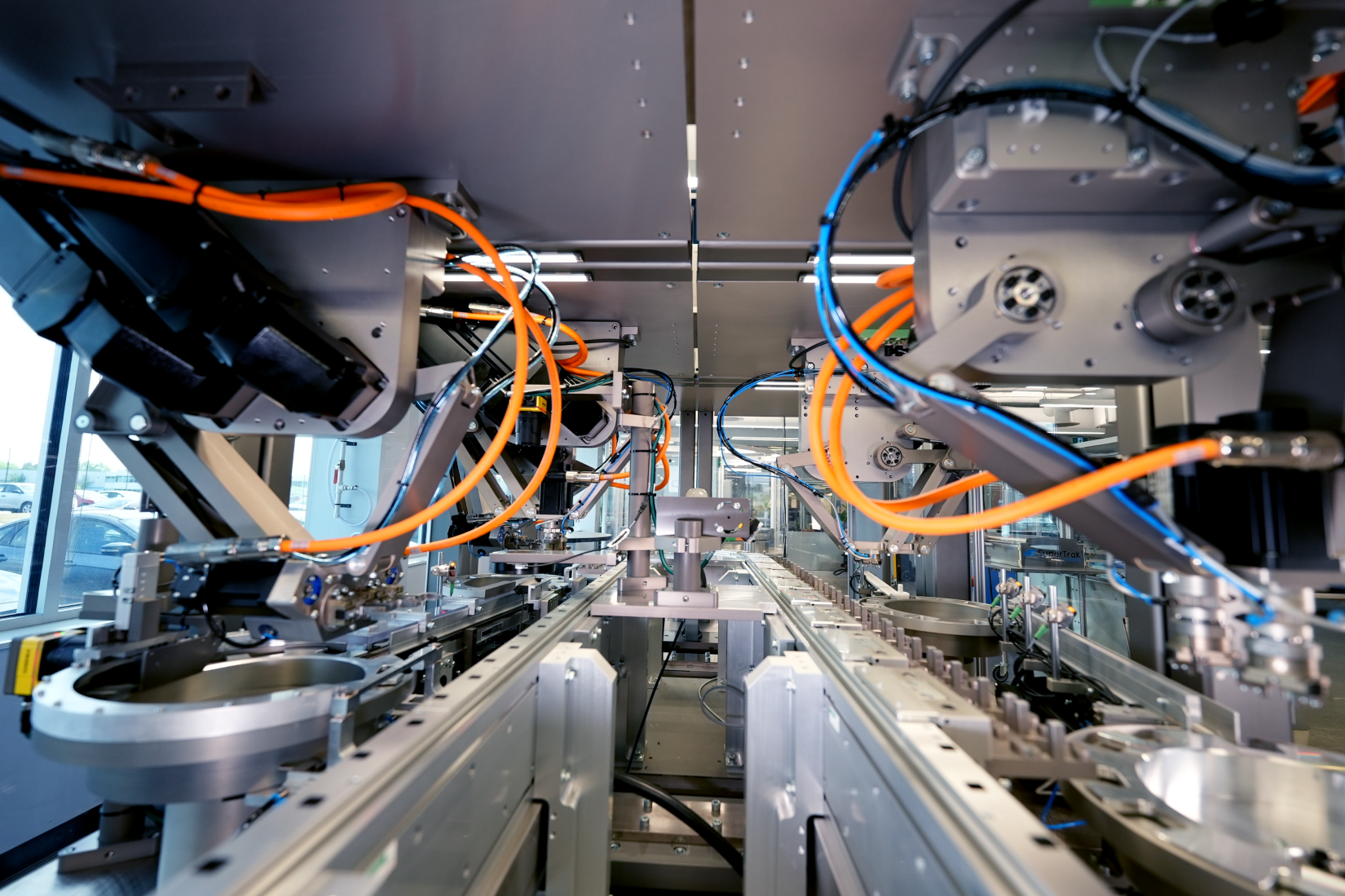

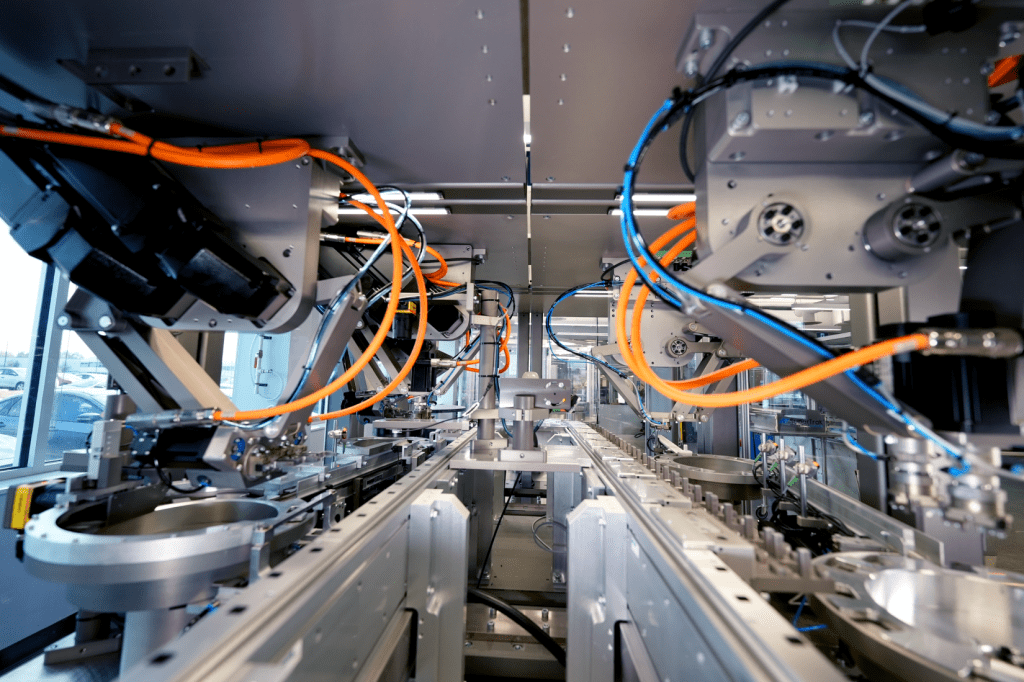

It is undeniable that automation is a powerful tool in manufacturing that can help businesses increase efficiency, reduce costs, and improve quality. It involves using various integrated technologies to automate tasks and processes that were previously done manually or by aging machinery, freeing up time and resources for more valuable activities. Given the planning and investment that comes with the decision to automate, there are some key considerations around the strategy to introduce automation.

There are many different strategies businesses can use to implement automation, and the best approach will depend on the specific needs and goals of the organization, there is no one size fits all approach to automating. It’s important to remember that automation can mean more than physical assembly; it can also be information systems and administrative processes.

“Keep in mind not all processes need to be automated at once; you can integrate ‘islands of automation’ for specific processes or assemblies you’ve identified as particular pain points.”

If supply chains or geo/political considerations are pushing the automation discussion further along in your operational planning, here are a few key considerations to keep in mind when developing an automation strategy:

1. Identify key areas for automation: The first step in implementing automation is to assess your business processes and identify areas where automation could be beneficial. This could be a simple assembly process with a high degree of repetition, or it could be a very complex process, where manual assembly leads to high defects.

Keep in mind not all processes need to be automated at once; you can integrate ‘islands of automation’ for specific processes or assemblies you’ve identified as particular pain points.

Engaging a qualified third party to lead this review and help develop the business case is often a wise investment at this stage. In terms of employee acceptance, it’s often easier than trying to boil the ocean, especially when trying to get stakeholders on board with a major change initiative.

2. Set clear goals and expectations: It’s important to have clear expectations in mind when implementing automation and what realistic improvement goals you are looking to meet. This might include reducing costs, improving efficiency, increasing accuracy, increasing employee safety, or freeing up time for more valuable activities. Ensure that those metrics are measurable and that your expectation is realistic. An example would be ‘Improve OEE from 65% to 85%’, or ‘Reduce rejects from 15% to 5%’, versus ‘Reduce defects to zero on Day 1.’

3. There is no silver bullet: Artificial intelligence (AI), machine learning, and deep learning are big buzz terms in automation but they are not one size fits all, nor do they make sense for all applications.

Most automation, in terms of assembly and manufacturing, will gain only marginal improvements with AI (for various reasons), so be open to more conventional solutions you may be offered. Investment in cutting edge solutions to build a better mouse trap may not be justified when a proven platform addresses your need. Rather than trying to fit the round peg in the square hole, perhaps there is a simpler robotic solution that doesn’t require advanced programs and big data lakes to create massive improvements.

4. Two words – Continuous Improvement: As I mentioned before, do not try to boil the ocean all at once. When automating it’s important to implement a measurable solution and work toward improving that system using the data you gather from your monitoring systems. You will not operate a perfect system on Day 1; there will always be slight improvements that can be made as it operates in real time for your application.

Data collection and reporting is a key aspect of good automation so ensure whichever solution you choose, it is supported by a robust data intelligence program. You don’t want tens of thousands of data points that you need to sift through for information. You should be able to monitor the system for a baseline and receive actionable reporting to identify trends, be proactive, and help drive future improvements.

5. Lastly, it is paramount to communicate with stakeholders: Automation solutions can have a big impact on the way your business operates, so it’s important to communicate with stakeholders about the changes, especially the operators and manufacturing teams. Understanding exactly what will happen at each step of the implementation can allay fears and help ensure a smoother transition, minimizing disruptions to production.

Some of the best implementations I have seen involved getting the operators involved during the design phase, as they work on the product every day and have deep insights into the process and intricacies of the product or system. A sense of ownership and agency in a major

‘Investment in cutting edge solutions to build a better mouse trap may not be justified when a proven platform addresses your need.’

To conclude, implementing an automation solution can be a complex and multifaceted process, but it can also be a powerful tool to drive business growth and success. Careful planning, design and execution of the appropriate automation strategy with an experienced partner will allow businesses to unlock significant benefits and create a more efficient, effective organization.