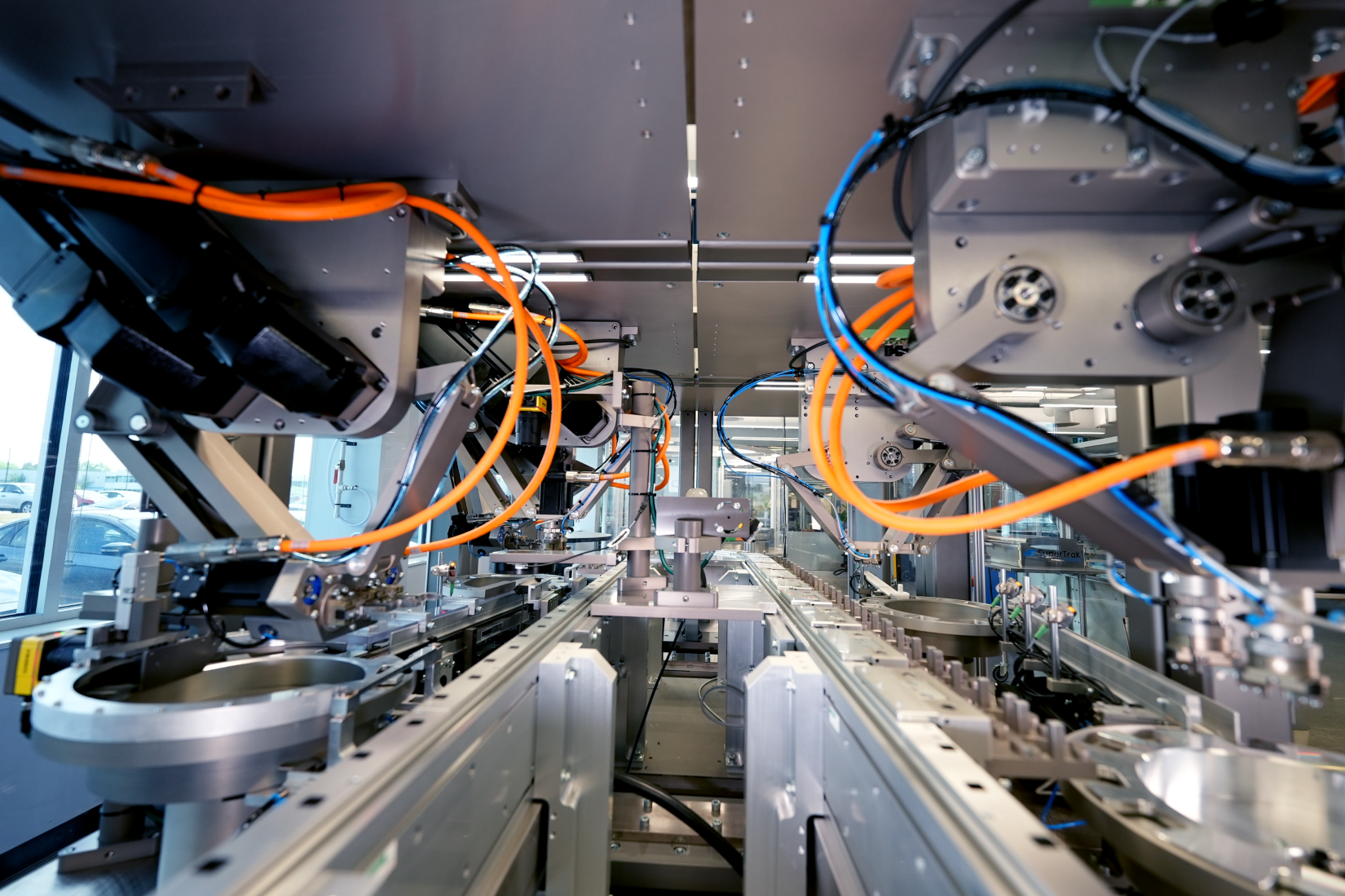

Product manufacturing begins with the introduction and feeding of components and ends when the product is ready for distribution. The systems that we design, build, and integrate for our customers incorporate a wide variety of processing and assembly capabilities. And if you have a unique requirement, we have the depth and breadth of experience to provide appropriate solutions.

You have high quality standards to comply with GMP requirements and deliver safe products to the marketplace. We understand the criticality of maintaining component and product integrity and avoiding damage. Trust us to design and build the appropriate materials management automation for your application.

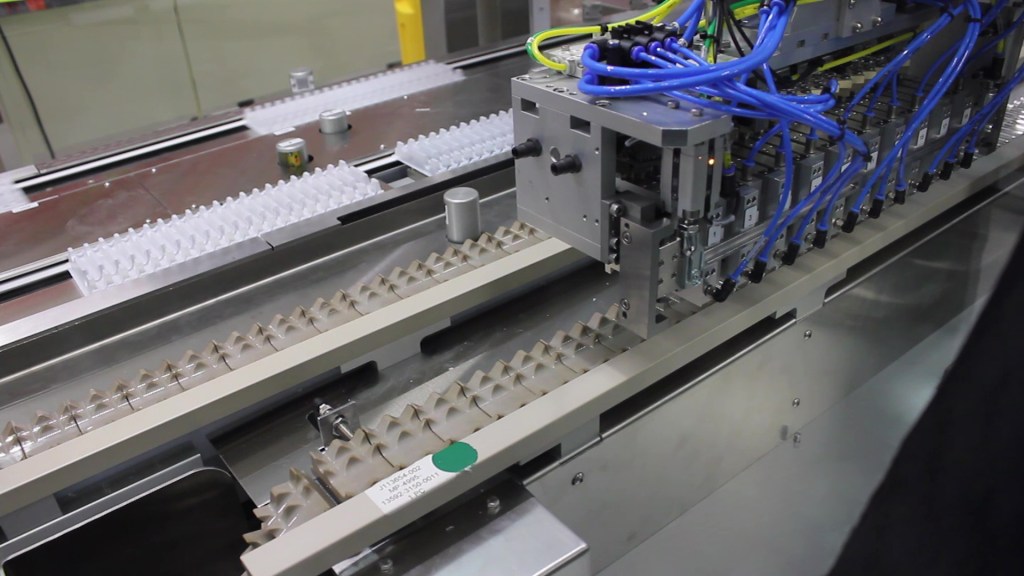

- Component logistics

- Feeding

- Pre-treatment

- Quality control

So many permutations and combinations of processes and assembly steps can be involved in the manufacturing of your products. Some of those steps might already be well-defined, while others may require ingenuity and careful development. Regardless of whether we identify and integrate a commercially available technology or custom-design a technology to meet your process requirements, you will have a seamless experience.

- Fluids based processes

- Forming

- Component manipulations

- Attaching, fastening, and bonding – laser, ultrasonic, adhesive

For the majority of products, manufacturing does not stop at assembly. Finishing steps such as labelling, cartoning, and case packing are necessary before distribution, marketing, and end customer use. Our portfolio of solutions includes the following:

- Labelling – laser marking, etching, ink jet, stamping

- Primary packaging

- Secondary packaging

- Kitting

Quality control and assurance are your top priority. So we build our systems to be fail-safe—every product is assumed to be defective until proven otherwise. We incorporate the appropriate automation into every manufacturing solution, so you can rest easy that your product meets your QC and QA requirements.

- Verification of incoming components

- Process monitoring and confirmation

- Quality attributes testing, e.g. dimensions, integrity, appearance, position, legibility

- Quality control sampling

- Performance testing

Information about your product, process, and performance is critical to your peace of mind while also satisfying regulatory requirements. We are mindful of the need for data accuracy, security, and communication, as well as analysis, reporting, and improvement. Contact us for more information about how we manage your product, equipment, and factory digital information for decision making, teaching, and learning.

Production Unit: Serialization or pedigree information at the individual product level

Batch: Data to support batch record requirements, electronic batch records

Machine: Data and analytics associated with machine performance

Line: Integration of disparate control systems, and data and analytics associated with overall line performance

Factory: Communication to and from MRP, BRP, and ERP systems

Artificial Intelligence: Learning from collected data for performance improvement

Sometimes we just have to show off a little. Neatly categorizing the solutions to various unique assembly challenges we have been presented with isn’t always possible. Here are a few innovative examples showcasing our ability to solve your unique assembly requirements.

Autonomous Intelligent Vehicles to deliver materials

Controlled environments for sensitive processed – Grade A, oxygen free, humidity controlled, and more

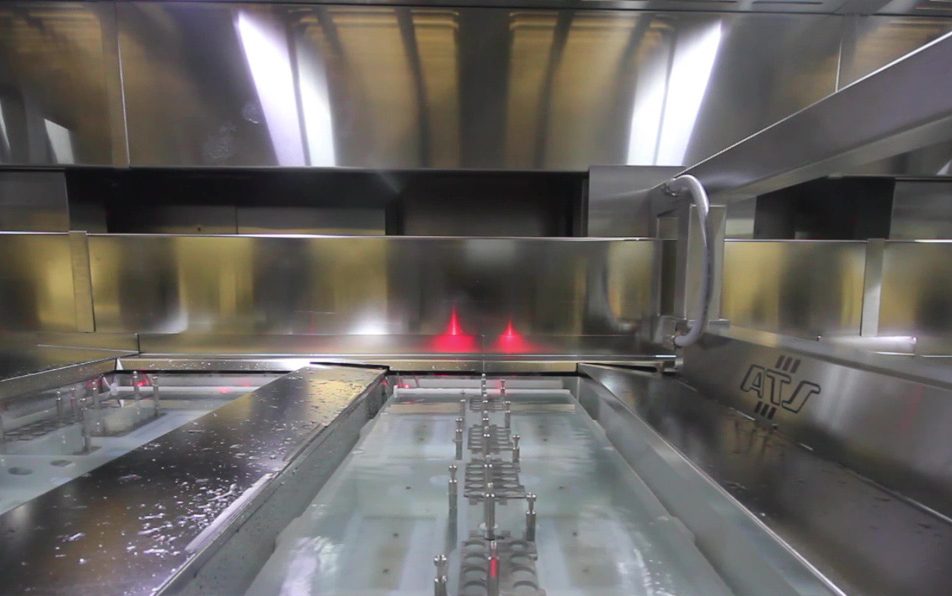

Washing systems for component cleaning

Wet benches for rehydrating, treating, or cleaning product

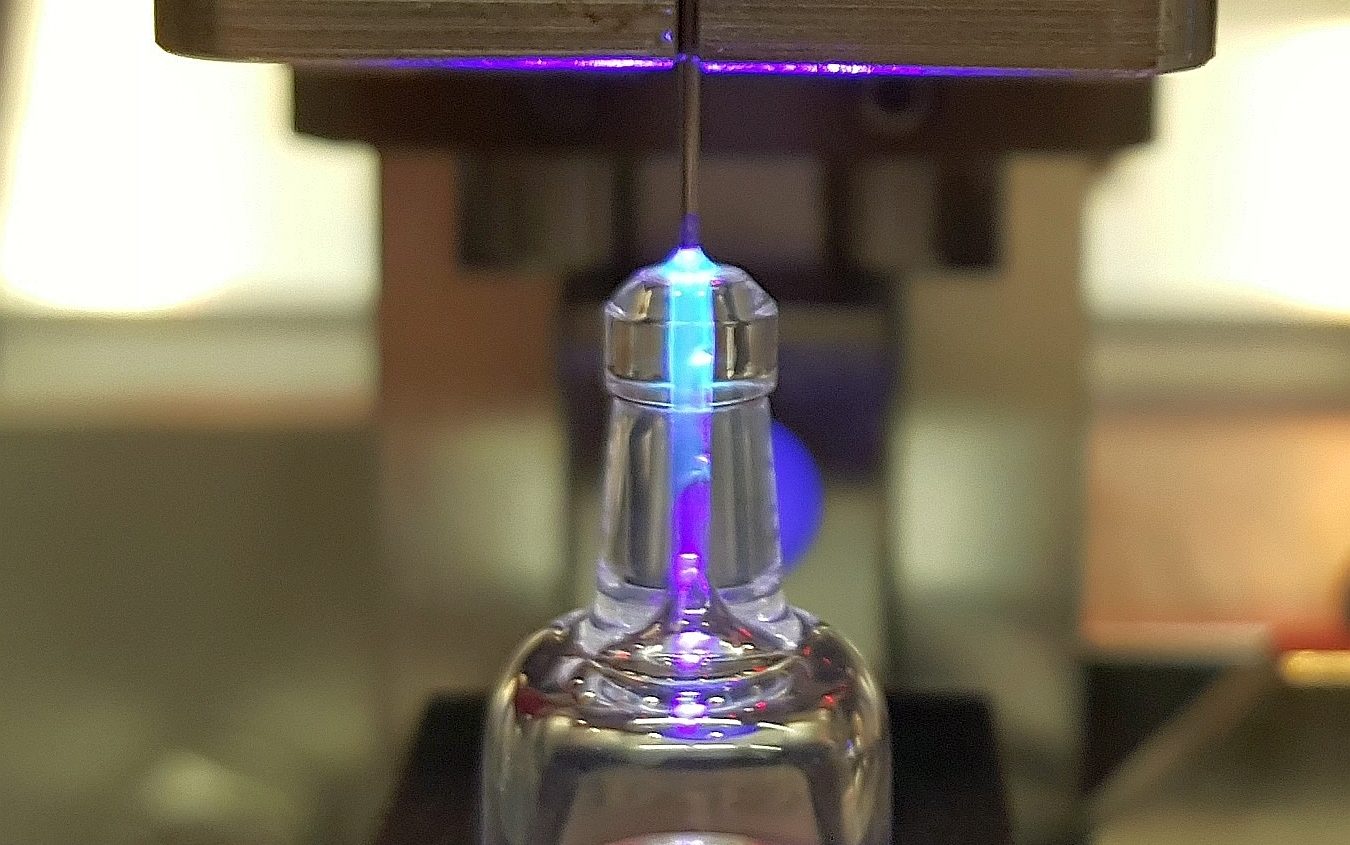

LED UV curing of adhesive for syringe assembly