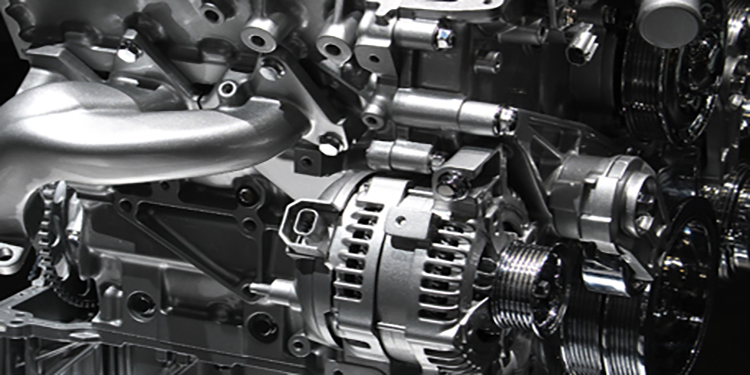

We have a long history of outstanding performance ranging from the assembly and test of the entire range of heavy duty diesel engines and transmissions.

We have designed, built and supported large engine assembly and test projects for manufacturers around the world.

These projects included all assembly, material handling, in process quality management, product management, and end of line final test.

The key to engine assembly launch success starts with product knowledge. By having on-staff engine experts, we are well positioned to meet your needs with the ultimate customer in mind, every time. Working upstream in the customer value stream allows us to best leverage and ensure that your capital investment has the highest value add as possible. Often this includes advanced team efforts such as Simultaneous Engineering activities and proof of principle simulations.

Looking for a partner not just a supplier? We are your complete engine assembly and test solution.

Expertise, Values, Benefits

- Turnkey product processing and system layout design

- Investment optimization

- Material handling simulation

- Plant & Facilities design consultation

- Clean and quite assembly environment

- Effective visual management

- Lean system design

- Optimum Ergonomic design/Safe transport

- Future system production volume growth/expansion

- Improved quality through use of RFID, BC scanning, smart pick bins, IPV, defect tracking/diagnostics monitoring and alarm notification

Additional Information

Battery Design Authority – What 90 Battery Lines Have Taught Us

Watch the Webinar On-Demand >

The Tangram Issue in Battery Testing

Watch the Webinar On-Demand >

Electric Vehicle Challenges: Are You Prepared?

Watch the Webinar On-Demand >

Discover The Key Element: EV Battery Testing,

Watch the Webinar On-Demand >

Hear What the Experts Have to Say on EV Battery Assembly.

Watch the Addressing the Battery Challenge Webinar >