Our engineers have helped meet the goals of numerous battery customers, creating terminal welding solutions which provide consistent, high quality electrical connections.

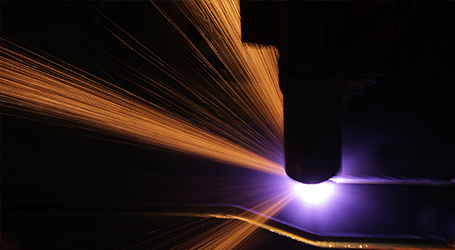

The electrical interconnects made in a battery are critical to battery reliability. With hundreds of bonds at the cell, module and pack level, a reliable joint is essential. Over the past 15 years on dozens of EV battery programs, ATS Industrial Automation has developed core expertise in the development and integration of various joining technologies. Ultrasonic welding, resistance welding and laser welding have all taken on varying degrees of importance as the technology has matured. ATS Industrial Automation has invested in in-house laser process development expertise to assist with welding process development.

Additionally the hermetic seals required in the welded housing joints are also an area where ATS Industrial Automation brings process development expertise to our customers, enabled by our in house laser expertise and established network of partners.

We are cell type agnostic, having delivered numerous systems utilizing cylindrical, prismatic and pouch cells. Our technology is readily deployable across a variety of battery styles.

ATS Industrial Automation has longstanding technology relationships with many of the key technology providers and has completed numerous projects utilizing a tight cooperation between the customer, the core technology provider and ATS Industrial Automation.