A LINEAR OR ROTARY BLOW MOLDING MACHINE? “PROGRESSIVE” IS BETTER.

Over the last two years, SIAPI’s R&D activities have focused on an ambitious goal: to design blow molding machines different from the linear blow molding series, which have always been the company’s core business, looking for higher production speeds to be achieved.

The simplest alternative would definitely have been to develop the rotary blowing machines, already produced by many other companies in the sector, which are complex in terms of design and use, but faster and more efficient. This solution, however, was risky, because it involved, among other things, being the last to enter an already saturated market.

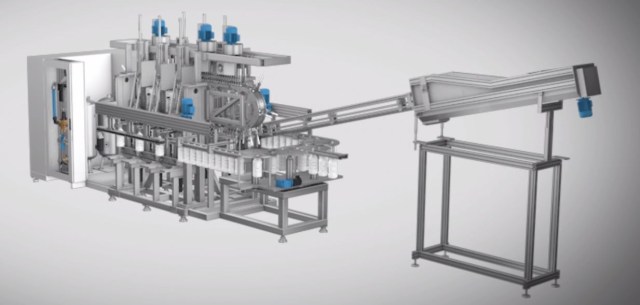

OUR team, therefore, decided to create a completely new machine, which overturns many of the unwritten rules of blow molding machine design. A machine with fixed molds but with a concept for distributing the preforms that makes it possible to obtain the same results as the rotary machines in terms of speed and continuity of container production: a Copernican revolution that goes by the name of progressive blow molding machine.

GALILEO SERIES

The new series has been named Galileo, in reference to the Italian father of modern science, a key figure in the scientific revolution through his support for the Copernican theory. Galileo series is the result of constant and determined research and development, which has led to the introduction of the revolutionary progressive preform feeding technology onto the market.

The production speed of the Galileo series is equal to that of rotary machines, but the revolutionary concept behind it offers many further advantages. Firstly, the machine no longer has to move molds weighing hundreds of kilograms, only the few dozen grams of preforms. In addition, with the molds being stationary, the distribution of high-pressure air, water and electrical signals is much simpler. This eliminates the central manifold needed on a rotary machine, which is the most expensive and most wear-prone component

ENERGY SAVING

In this context, it is only natural to expect significant energy savings from Galileo and, in this respect, SIAPI’s new creation also offers many benefits.

As already mentioned, with fixed molds there are no significant moving masses. But the real “energy revolution” lies in the position and structure of the oven.

Firstly, the preforms travel in pairs on tracks (intelligent trolleys) designed by the ATS Group’s SuperTrack company; taking advantage of this paired arrangement, the oven lamps radiate the pair of preforms from the centre. This, together with the presence of two mirrors on the sides of the oven, makes it possible to use 100% of the radiant energy of the lamps, in contrast to conventional ovens, which have a much lower energy efficiency. Secondly, the trolleys can vary the distance between them (“pitch”). In this way, the pairs of preforms always enter the oven at the minimum distance, so as to maximize the filling coefficient of the oven and to be able to design smaller ovens with respect to all the other machines.

The position of the oven has also changed: from the classic position “at the end” of the rotary and linear machines, it is now in the upper area of the machine, which allows it to have more compact and manageable dimensions: the length is in fact reduced by about 50%.

In this way, the total consumption of the Galileo is about half that of other blow molding machines of the same performance currently on the market

OTHER ADVANTAGES FOR THE CUSTOMER

Based on a logic of modularity, the new Galileo series allows the reduction of delivery times for machines and spare parts, as well as a general optimization of setup times and costs. It also minimizes maintenance costs and ensures maximum ease of use and intervention by the operator.

Flexibility is another key feature. In fact, the movements allow a blowing cycle that is adaptable to different needs and hourly production, while the management of the machine data and equipment allows a high level of control over the mechanical and electronic movements. There is also the possibility of excluding the operation of any faulty stations (reducing preform rejects) as well as close supervision of the production process. The machine can also operate with a reduced number of molds, for low-speed production or in the case of container prototyping.

A REVOLUTION FROM AFAR

Manuel Rosada and Marco Sgorlon, from research and development department, describe how this project was born “from the necessity, in close collaboration between Siapi and CFT, to supply complete lines for medium hourly production in a market segment occupied by rotary blow molding machine technology. The desire was to propose a technologically innovative system that would differ from rotary machines and their well-established systems. A system that would guarantee flexibility, ease of handling and high product (container) quality.”

“When we were asked to develop this machine”, they add, “we started out by considering designing a rotary machine. Over time, as the project became more concrete, however, we began to highlight its limitations and wondered if it would be possible to create something that would overcome them. So we looked at the strengths of both rotary and linear systems and wondered about how they could be combined into the same machine. The result is a modular machine, which can be expanded into the field of high productivity.”

With this new project, Siapi affirms its innovative skills, already demonstrated in the past in the large container market, and enters market segments in which it has not been present up to now.

The choice of the definition “Progressive Blow Molding Machine” is not accidental, but is intended to describe the gradual steps that lead from the preform to the single container, according to a progression of movements of the blowing modules. The same definition also serves to affirm the important evolution and emancipation with respect to the traditional methods of blowing used up until today.

All this has been achieved thanks also to the integration of SIAPI into the ATS group, manufacturer of the SuperTraks. The machine is therefore manufactured with the use of technologies developed solely within the group. This ensures complete access to product know-how, guaranteeing maximum application reliability.