With every project that crosses our path, our team welcomes new challenges presented by our customers. Sometimes it’s custom-designed equipment. Other times, they seek a standard platform solution that reduces their risks and gets their product to the market fast, especially if that product saves lives, as with the COVID vaccine. This is where Symphoni™ comes in. An innovative, standardized, digital assembly platform that is fast, flexible, and precise. Every Symphoni machine is configured from pre-tested, pre-validated, plug-n-play building blocks and standard control software called Symphoni “Servo Apps.”

In this case study, our Project Manager, Eric Dean, walks us through the customer’s requirements and why Symphoni Platform is the perfect fit that met and surpassed their needs. (Note: for confidentiality purposes, this customer has been given the pseudo name Scorpion.)

Before we get into the inner workings of Symphoni, please introduce yourself.

My name is Eric Dean, Project Manager at ATS Life Sciences in Cambridge.

Can you tell us what was important for this customer when they came to ATS for automation equipment?

They came to ATS looking for a trusted partner to build automated assembly equipment that they could rapidly deploy to assemble syringes for the US government rollout of the COVID-19 vaccine.

Their interest in Symphoni technology to produce the subassembly for their product was two-fold.

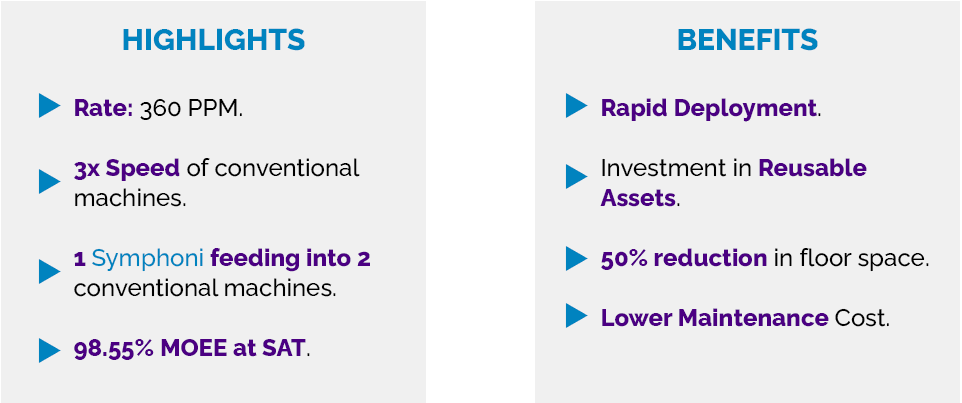

First, they wanted to reduce the equipment footprint in their factory. We achieved their target by doing the subassembly on a Symphoni platform. Typically, a Symphoni machine is 30% – 50% smaller than a conventional machine and runs at 3x the speed. With Symphoni, we increased the output on a single machine and fed the subassembly to two final machines.

Second, the client had a contract with the US Government. Their product was needed for rapid COVID-19 vaccine rollout. Every Symphoni machine is configured from standard building blocks built and tested to ATS’s inventory. Because 75% -85% of every Symphoni machine is standardized, the project process was executed in parallel instead of sequential, typical for traditional project specific equipment. The high level of standardization also reduces risks for the project team and the customer.

Can you walk us through what this machine does?

Sure, let me walk you through the process of our Symphoni Scorpion Machine.

We see the first station is the SEAL CELL, a 2-up with 2 inline lanes that place the seal onto the pallet.

The next station is the PLUNGER HANDLE, a 2-up, 2 station where the plunger handles are picked. Here, the seal is inserted onto the plunger handle, which is then placed into the gripper fingers and travels around on ATS’s SuperTrak CONVEYANCE™ to where the other parts to be assembled are added.

The PLUG STATION, a 2-up station, picks up a set of straws that is then inserted into the plug all the way down into the plunger handle.

And the last station we have is the CAP STATION, which is different from the previous stations I mentioned. This is a 4-up single station where the caps are put on top of the plunger handle before being released to the inline track and into the final assembly.

So clearly, Symphoni is versatile and can be configured to meet the customers’ requirements. This is a good thing! Now, where does the quality inspection come into play?

It happens at the final stage of the assembly. Here is where the plungers are inspected for quality. The rejected parts come down through the shoot into a separate bin.

The parts that meet our quality requirements come into the off-load track. Here, they will either be picked by the robot and placed into cell 20, which is integrated with the Symphoni assembly platform or dumped into a bulk off-load and into our cell 30. This part is integrated with the line.

Thank you for your time, Eric, in walking us through the Scorpion case study with us.

No problem, glad to show you around.

Want to learn more?

- Email us at SymphoniTech@ATSautomation.com

- Sign-Up for our Quarterly Newsletter.

- Connect with us @SymphoniTech on LinkedIn, YouTube, Twitter and Facebook.