Lorem ipsum

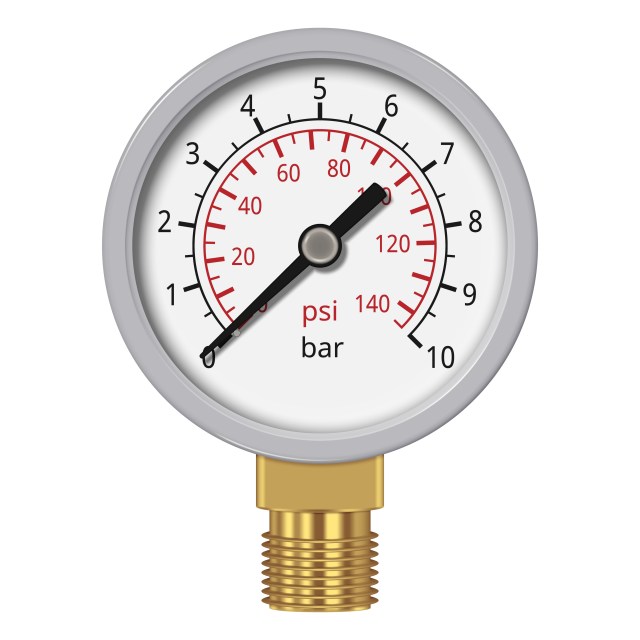

Machines serve multiple functions, such as assembling pressure gauges, sensors, and Tier 1 automotive components (mirrors, lights, motors, keys, EDU & ECU parts, hairpin preparation). Common machine processes include:

- Loading/assembling parts

- Welding (including ultrasonic)

- Magnetizing, gluing, pressing

- Labeling, printing, marking

- Inspecting, testing, rejecting

- Packaging and unloading

High precision is required, with some processes needing repeatability within ±0.05mm.

Tray handling is essential for managing parts between machines, including void elimination.

The challenges solved

The most common challenges of such a manufacturer are cost efficiency and high yield. Finding a leaner solution for a complex process is the key to building a viable production line within cost and space constraints, and early simulations are often required to ensure that throughput expectations are met.

Smart Conveyance Goal

The ultimate goal for Smart Conveyance in such applications is leaner automation, provided that it achieves similar or higher throughput and comparable cost to a machine-based standard conveyance system.

Smart Manufacturing Solutions

SuperTrak CONVEYANCE™ brings value by enabling complex motion that can vary at each process step and sometimes become part of the process itself, thereby reducing the need for tooling or stations and increasing the number of process steps possible at a single station or location.

Addressing Core Needs

As this motion is controlled by software, carrying or adding several products on the same line becomes possible with reduced efforts, and traceability of products becomes possible with the identification of each shuttle.

Leaner automation

Larisys Industries successfully implemented an assembly machine based on a 4m SuperTrak VERTICAL10™ system for a wiring harness application. The machine’s size is estimated to be half that of a standard conveyance solution, and the line’s accessibility is vastly improved to facilitate maintenance.

The SuperTrak technology is disruptive because of its speed, precision, compact design and capability to be easily configurable.

Larisys Group

SuperTrak CONVEYANCE™ Users

Showcase Their Machines in Action:

Get Started with Smart Conveyance

Speak with a SuperTrak CONVEYANCE™ team member today to see how you can unlock your process’s potential by levering higher speed, increased precision, and independent shuttle control.

If you have an upcoming project, now is the time to start thinking about your conveyance system.