Discover Smart Conveyance

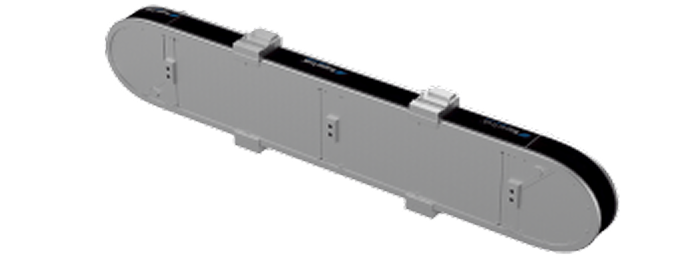

SuperTrak CONVEYANCE™ is a magnetic conveyance platform that enables building more cost-effective, space saving assembly automation with reduced risk and effort.

Focus on your specific application while the platform’s integrated functionality manages the motion in real time.

Independent Shuttle Control

Speed: up to 4 m/s

Precision: +/- 0.01 mm repeatability

Independent Shuttle Control

Powered by linear servo motor technology, SuperTrak CONVEYANCE™ allows independent shuttle control with fast and precise motion, providing automation designers with the flexibility required to increase productivity and minimize space.

Independent Shuttle Control delivers more cost-effective and space-saving designs by:

Independent Shuttle Control delivers more cost-effective and space-saving designs by:

Avoid Duplication

Eliminate parallel stations to streamline workflow and reduce redundancy.

Use Offsets

Replace duplicate tooling with offset strategies to save time and resources.

Reduce Buffers

Minimize buffer sizes to improve efficiency and reduce system complexity.

Optimize Stations

Maximize the use of each station while simplifying the overall process.

Speed

As a magnetic conveyance platform, SuperTrak CONVEYANCE™ delivers higher performance and leaner automation. SuperTrak CONVEYANCE™ offers

high speeds

low settling times

rapid acceleration

to reduce cycle times and overall productivity.

Precision

Increased precision means leaner automation as it reduces:

the amount of stop and locate tooling

the required engineering effort

the burden on operations to maintain complex tooling

Use SuperTrak CONVEYANCE™ high precision and low settling time to simplify the design and operations of the final assembly machine.

Products

SuperTrak HORIZON3™ →

Can carry up to 3kg per shuttle with a shuttle-to-shuttle pitch as low as 50mm.

SuperTrak HORIZON10™ →

A high-performance magnetic conveyor for leaner manufacturing automation reduces the size of assembly machines.

Compare the Product Portfolio

Here’s How We Help

Scaling & Redeploying Automation →

Modular track sections can easily be added or removed with little engineering effort. This allows manufacturers to align their automation to their business requirements.

Factory Floor Space Optimization →

The SuperTrak CONVEYANCE™ platform offers independent shuttle control, higher speeds, lower settling times, and greater precision.

Market & Product Uncertainty →

Integrated functionality reduces needed tooling and minimizes floorspace, while multiple configuration options allow you to fit your automation system into required spaces.

Start a new Project & Get a quote

Use SuperTrak CONVEYANCE™ high precision and low settling time to simplify the design and operations of the final assembly machine.