Orise Digital AI

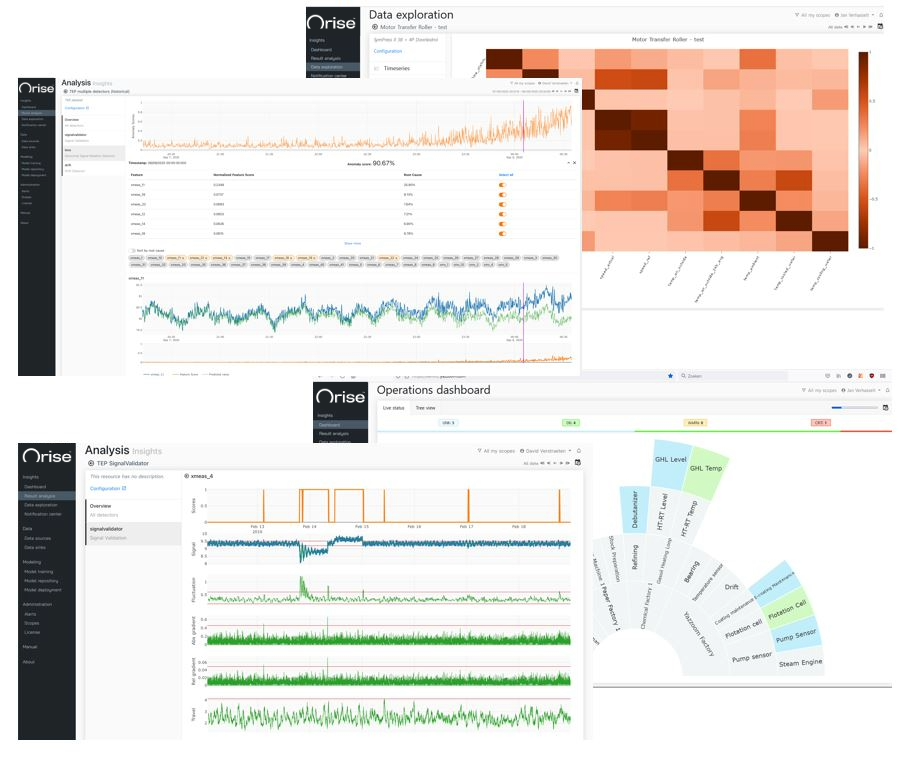

Our Software Solution for AI-Based Anomaly Dectection & Industrial Analytics

Orise Digital AI transforms the way industries monitor, manage, and optimize their operations. By turning raw data into actionable insights, Orise empowers businesses to achieve peak efficiency, reduce downtime, and enhance overall equipment effectiveness (OEE).

Whether you’re operating assembly lines, packaging systems, or continuous production processes, Orise Digital AI is the advanced solution designed to meet your needs.

Advanced AI-powered Features

Anomaly Detection

Orise Digital AI continuously learns what “normal” looks like for your sensors, machines, and control systems. When something deviates—even slightly—it alerts your team.

- Detect unexpected setting changes, control software issues, and abnormal signal patterns.

- Use dedicated models for assets like motors, valves, pumps, and drives.

- Accelerate root-cause analysis with AI insights on what’s going wrong and why.

This feature enables real-intervention when needed and helps you act before small issues become big obstacles.

Click here to learn more about our features.

Predictive Models

Build self-service AI models that forecast equipment failures or product quality metrics—without needing a data scientist.

- Predict failures before they cause downtime.

- Create virtual sensors to estimate lab measurements (e.g., paper strength or chemical properties).

- Leverage pre-processing tools and interfaces tailored for industrial use.

With industrial-grade data pre-processing and easy-to-use interfaces, teams can start optimizing processes immediately.

Click here to learn more about our features.

Micro-Stop Detection

Short production stops—“microstops”—often go unnoticed but can cause major throughput losses. Orise Digital AI detects these small disruptions in real time by monitoring I/O signals.

- Classify and report invisible slowdowns.

- Pinpoint causes using intuitive browser-based dashboards.

- Improve OEE by addressing high-frequency interruptions.

A few seconds reclaimed per stop adds up to major productivity gains.

Click here to learn more about our features.

Soft Sensing Monitor

The Soft Sensing Monitor uses AI to predict hard-to-measure or costly variables—like moisture or paper strength—based on existing sensor data.

- Estimate product properties in real time without lab tests.

- Improve quality, reduce waste, and cut costs.

- Deploy across lines for smarter, sensor-free insights.

Used in industries like pulp and paper to boost control and performance.

Click here to learn more about our features.

Asset Health Performance

Orise Digital AI continuously monitors the health of your critical equipment—motors, compressors, valves, control loops, and more.

- Detect degradation early to prevent breakdowns.

- Extend asset lifetime with predictive maintenance.

- Adapt to any data system or IIoT platform.

Real-time visibility enables smarter decisions on asset reliability and lifecycle planning.

Click here to learn more about our features.

Golden Production Run Advisor

This feature identifies the process conditions behind your best production runs and gives real-time feedback to help replicate them.

- Learn optimal settings using multivariate centerlining.

- Alert operators when current values deviate from golden benchmarks.

- Standardize high performance across shifts.

Operators receive actionable advice on maintaining peak output—manually or through automated control.

Click here to learn more about our features.

Control Performance Degradation Detection

Control loop degradation is a common cause of process variability. Orise Digital AI’s CPDD (Control Performance Degradation Detection) monitors control loops and actuators using a mix of AI and classic metrics.

- Track oscillation, saturation, and imbalance.

- Alert only when real degradation is detected.

- Enhance Advanced Process Control strategies.

This ensures more stable processes, better product quality, and fewer manual interventions.

Click here to learn more about our features.

Easy to Use Industrial Predictive Analytics, also for Non Data-Scientists

With self-service tools, Orise Digital AI allows domain experts to build models that anticipate unwanted events such as technical issues, used for predictive maintenance, or quality problems.

Data pre-processors, predictive models and interface developed specifically for industrial applications are available at your fingertips.

Key Benefits

- Maximized OEE: Enhance operational availability, production performance, and quality metrics with real-time insights and proactive monitoring.

- Cost Savings: Transition from reactive to predictive maintenance, saving on labor and operational disruptions.

- Sustainability Gains: Minimize waste and reduce energy consumption.

- Extended Equipment Lifespan: Detect early signs of asset degradation to prevent further damage and costly downtimes.

- Enhanced Decision-Making: AI-driven insights empower operators and managers to implement smarter, faster solutions.

- Seamless Integration: Easily plug into your existing infrastructure for a smooth adoption process with minimal disruptions.

Designed for Versatility

Orise Digital AI’s solutions are optimized for a wide range of industrial setups, including continuous, batch, and discrete manufacturing processes.

Whether analyzing sensor data from packaging lines or fine-tuning control software for chemical plants, Orise Digital AI adapts to your specific needs.

With intuitive visual interfaces, pre-built data preprocessors, and self-service tools, Orise Digital AI empowers engineers, operators, and reliability experts to build predictive models that anticipate issues like technical failures or quality problems—enabling predictive maintenance without the need for data science skills.

Powerful AI is placed directly in the hands of your team, making advanced industrial predictive analytics accessible and easy to use—no coding required.

.

Customer Case Examples

Tenneco uses Orise to monitor complex automated assembly lines.

By analyzing PLC signals, the system identifies early signs of bottlenecks and failure, helping improve throughput and uptime.

By analysing the PLC signals, the tools help Tenneco detect early signs of issues causing low throughput or future failures and to faster diagnose the root cause of performance issues affecting throughput.

With better, more detailed, analytics and reporting of the line functioning, data-driven decision-making improves the operations and maintenance of the equipment.

This way, Tenneco can ensure higher equipment availability and more consistent asset performance.

Agfa integrated Orise as an AI layer on top of existing alarms.

It now provides early warning of anomalies weeks in advance, allowing for timely intervention and predictive maintenance.

At Stora Enso’s Langerbrugge site, Orise continuously monitors over 600 assets and 30,000 signals.

It detects early degradation in motors, valves, and control loops—cutting downtime and improving diagnostics.

These cases demonstrate Orise’s ability to optimize operations and enhance decision-making.

Who uses Orise Digital AI?

- Manufacturers looking to improve equipment reliability and throughput.

- Process industries focused on quality control and predictive maintenance.

- Machine builders aiming to enhance value with integrated analytics features.

- IoT platform developers seeking advanced AI tools to augment their solutions.