MPC Platform

The MPC Platform in a Nutshell

The MPC Platform is the APC technology that allows operating companies to generate sustained benefits with high ROI and with a low Total Cost of Ownership.

It is capable of handling applications ranging in scope from one single distillation column to a full ethylene plant.

The MPC Platform

A suite of tools that allow the easy development and deployment of an APC application

Orise Digital’s MPC Platform software creates value by continuously optimizing the key process parameters online, in a closed loop, keeping the plant in the most economical operating point every minute of every day, 24/7.

To be able to do that, the MPC Platform predicts the plant behavior, accounting for plant disturbances and takes all plant constraints into account. This will result in:

- Less equipment wear and tear, thanks to reduced process oscillations

- Fewer alarms

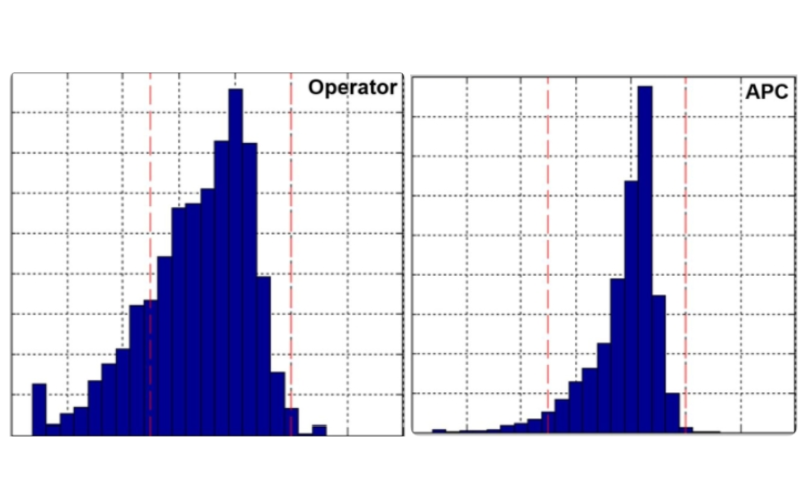

- Minimal operator interventions

- More efficient plant operations

- Higher production

- Less specific energy consumption

- Better quality control

- And more

- MPC Acquire: Quick and easy tool to start data collection from your DCS

- MPC Discovery: Modeling package that allows you to build dynamic models based on plant data

- Provides ability to include a-priori knowledge about the process in the identification cases (for example: known gain ratios, known delays, etc).

- MPC Architect: Offline configuration and simulation package for MPC and soft sensor development

- MPC: The MPC controller that optimizes your plant operation on a minute-to-minute basis

- The soft sensor accurately estimates product qualities like concentrations, melt flow rate, particle size distribution, all in real time

- MPC Viewer: Web-based operator and engineer interface to the control application

- Access and authorization levels are role-based and fully configurable

The Benefits of Using the MPC Platform

- Flexible licensing system (perpetual, term)

- Proven technology used on ammonia, urea, nitric acid, ammonium nitrate, CAN/NPK

- Previous customers include Yara worldwide, Sabic, Nutrien, Fatima, Engro, Fauji, OCI Nitrogen, Igsas, and more

- Proven technology on petro-chemical processes of BASF, Dussup, Ineos Phenol, Ineos Oxide, and more

- Proven technology on cement plants as shown by our APC partner for cement: ES-Processing

- Intuitive configuration and use

- Integrates with most DCS and PLC systems