Tomato processing

Our complete lines for tomato processing are designed to ensure excellent preservation of the organoleptic characteristics of the product.

There is a word that is often overused by companies: leader. It comes from the Old English word “lædan”, meaning ‘to go before as a guide’. Well, when we talk about tomato processing, we are not afraid to say that CFT Group is a true leader.

Since 1945, we have been offering a wide variety of tomato processing machines and complete lines: from the production to bottling or canning of tomato products, such as tomato puree, paste, sauce, diced tomato pulp or peeled tomatoes.

advantages of CFT tomato lines

- Large capacity lines: ability to handle large quantities of incoming product (up to 3,000 t/24h) with one single line for tomato paste or up to 10,000 t/24h with multiple lines

- Perfect preservation of the organoleptic features of the final product:

- Color up to a/b 2.2-2.3 (Hot Break) and a/b 2.4-2.5 (Cold Break), with Lightness up to 26-28 L (HunterLab measurements)

- High viscosity and very low Bostwick consistency index (lower than 2°)

- Flavor that preserves the freshness of ripe tomatoes

N.B: The data above also depend on external factors, such as the quality of the incoming product.

- Flexible and multipurpose lines: it is possible to obtain products with different viscosity values with the same line at the same time

- Delicate treatment: minimum thermal stress on the product due to low temperatures in the evaporator finisher. In particular, the residence time of the product inside the Apollo MVR evaporator is around 5 minutes and the Δt between the condensing vapour and the product is maximum 6-8°C.

- Elevate performance:

- Long uninterrupted production cycles: in the case of an Hybrid evaporator it is possible to wash the plant without stopping the production due to the opportunity to wash one evaporator at a time and due to the short duration of washing cycles

- Maximum yield thanks to a minimum production waste (around 2%)

- Process monitoring: patented supervision system (RCView) of the line and all the processing steps; data storage up to one year back and tele-assistance with the ability to remotely control machines installed all over the world.

STAGES OF TOMATO PROCESSING

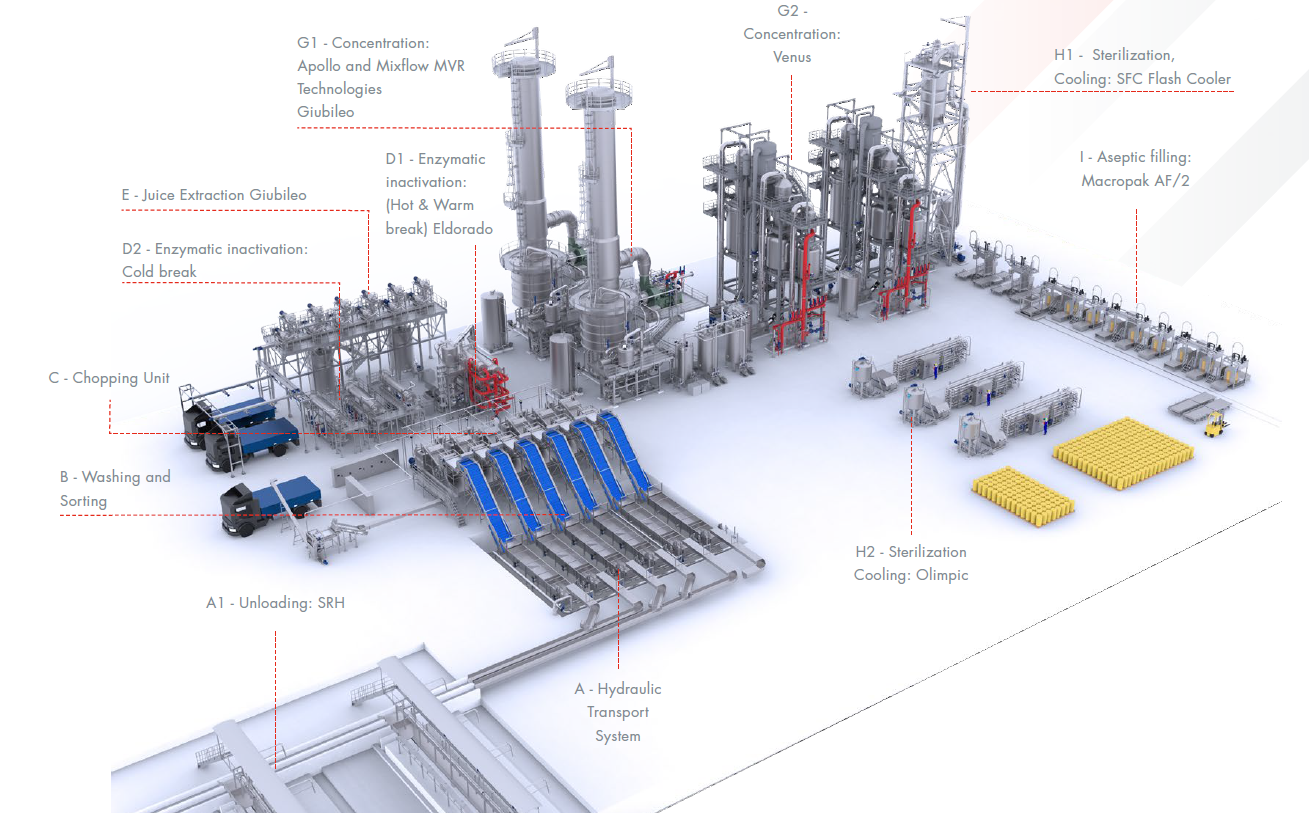

COMPLETE TOMATO PROCESSING LINE

1. Hydraulic unloading and transport

In a tomato processing line, the product can be received:

- In crates or bins: the raw material is unloaded into the transport channel via an automatic dumper;

- Loose: the unloading takes place by flooding the bin through adjustable pipes; the product is separated from the water by an inclined grid or roller conveyors and the tomato is then collected in a separation tank, fed with cleaner water and equipped with a chain conveyor to automatically remove foreign bodies.

At this point the product is conveyed to the processing lines.

2. Washing and sorting

Tomato sorting can be performed:

- Manually on roller conveyors in two phases: the first, in which the roller conveyor is inclined and where the separation of the product from water, foreign bodies, etc. takes place, and then the washing using a series of sprayers; the second, in which the roller conveyor is horizontal, and the tomato rotates on itself, to allow accurate checking on the part of the operators;

- Electronically: through optical sorting sensors and/or digital camera optical sorters produced by our company Raytec Vision.

3. Chopping

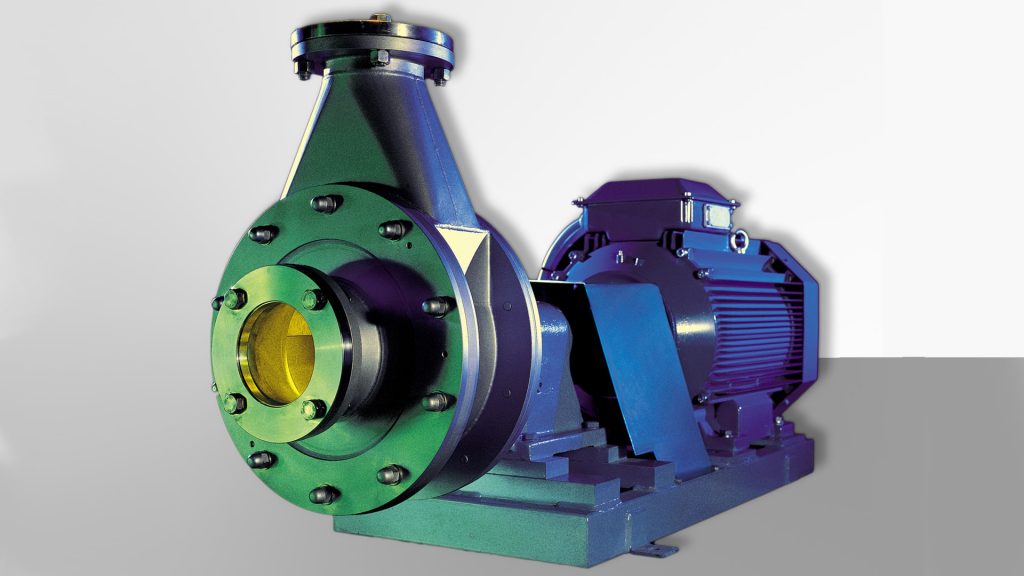

The washed and sorted tomatoes need to be squashed to optimize the subsequent heat treatment phases. The BT60 chopping pump, inserted in both the Cold-Break and Hot-Break technological cycles, guarantees a uniform and fine consistency of the crushed product. As regards the Hot Break process, extremely low synaeresis values can be reached by means of breaking temperatures that are almost 4°C lower than the standard values, a factor which also allows considerable energy savings.

4a. Enzyme inactivation (hot break)

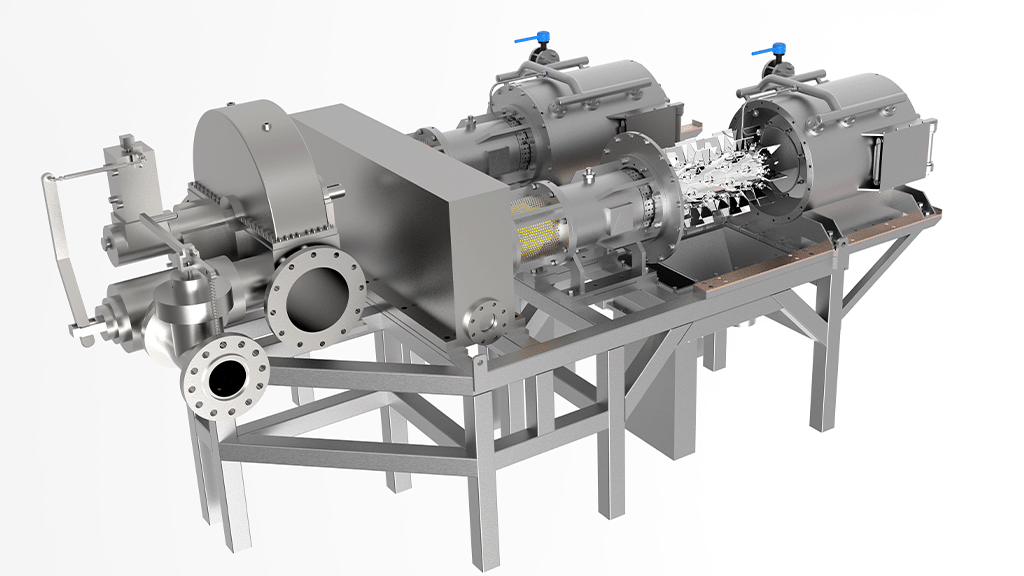

The Eldorado inactivator, which inactivates the pectolytic enzymes, is used for the production of tomato products that need enzymatic inactivation between 85°C and 110°C (Hot Break). Thanks to its high recirculation flow rate and the particular geometry of its patented heat exchangers, the Eldorado system can operate at its maximum efficiency for long periods of time even in the presence of foreign bodies.

4b. Enzyme inactivation (cold break)

Tomatoes intended for the production of Cold Break products are heated in the Tube nest heat exchanger, which is a patented cold break treatment system for enzymatic inactivation of tomato. It perfectly preserves the natural flavour and colour of fresh tomato. By varying the treatment temperature, a final product of various consistencies is obtained.

5. Juice extraction

The preheated tomato juice is sent to the extraction / refining phase, which is carried out in the Giubileo extractor using the principle of centrifugal separation by means of adjustable blades. This operation is able to eliminate unwanted parts of the fruit, such as seeds and peel. The high efficiency of the separation process allows a high quality juice to be obtained and minimizes moisture in the waste.

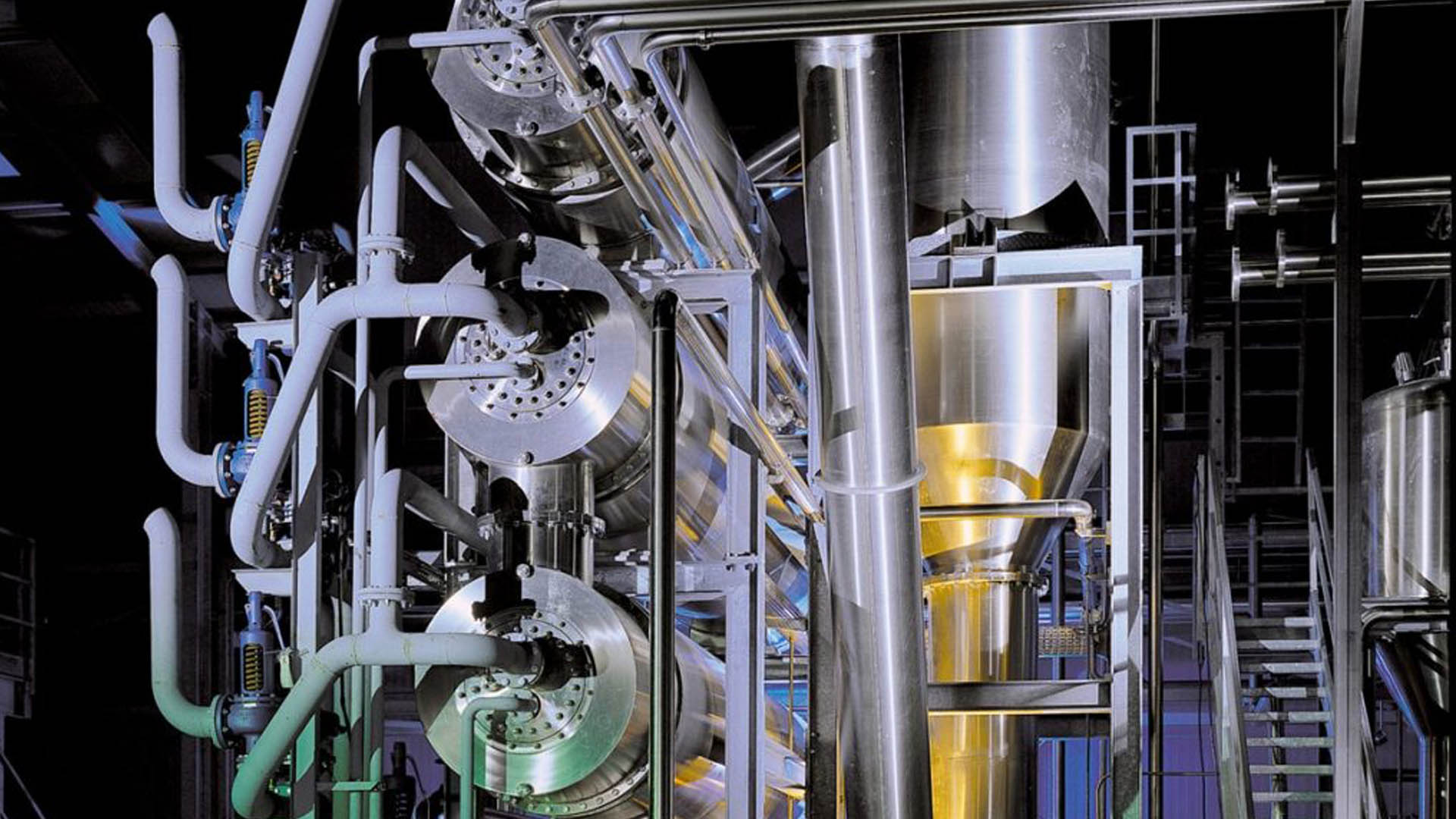

6. concentration

The refined tomato juice can be sent to an initial concentration phase (from 5° to 8-10° Bx) in the Apollo MVR, which is a falling film evaporator with Mechanical Vapour Recompression (MVR) technology. It allows up to 98% steam savings thanks to its mechanical recompression of acidic vapours and ensures excellent quality of the final product. According to the tomato product (tomato puree, paste, sauce, etc.) one wants to obtain, the Apollo evaporator can also be combined with the Mixflow (up to 15-16° Bx) and/or the Venus, which is the only evaporator capable of achieving the maximum requested concentration. In this way, maximum energy efficiency can be achieved.

7. Sterilization and cooling

- Aseptic Flash Cooler: the best solution for the treatment of large volumes of product and for long operating cycles. Sterilization takes place by direct injection of culinary steam into the product and cooling by vacuum expansion (flash). This system guarantees maximum processing safety, aseptic conditions and the integrity of the final product;

- Olimpic TC sterilizer: the product is subjected to a thermal cycle by means of indirect heat exchangers with high production capacity, maximum heat exchange efficiency and process uniformity.

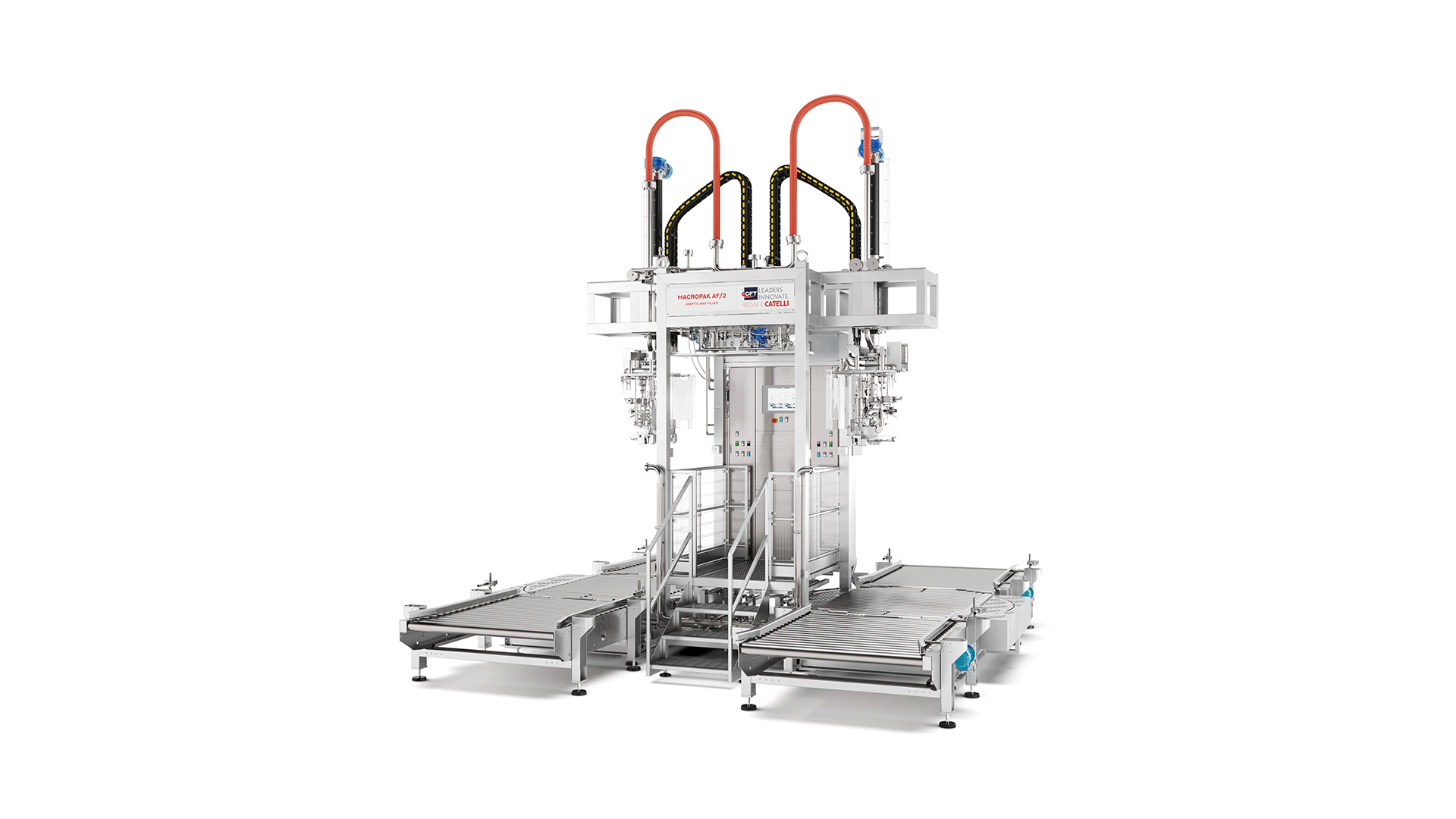

8. Aseptic filling

The sterilized, cooled product is filled into various sized pre-sterilized flexible bags by means of aseptic filling heads. The high degree of automation of the Macropak filling machines and the checking system guided by a microprocessor with continuous monitoring of all the working parameters, guarantee the sterility of the packaged product.

EXAMPLE OF tomato processing line