Sterilizers and Pasteurizers

A full sterilizers and pasteurizers’ portfolio featuring different technologies depending on the specific product and application.

We are internationally renowned for our leadership in the field of sterilization and pasteurization for a huge variety of food and liquid food products. Our wide range of sterilizers features different technologies (tubular/concentric, tube/scraped surface, heat exchanger systems, etc…) depending on the specific application industry (liquid food/ semi-liquid and viscous food).

From our Olimpic range (a wide sterilizers’ portfolio dedicated to food and liquid food products) up to our innovative Stematic Long Run (specifically engineered for sterilizing Milk and Dairy products with UHT technology).

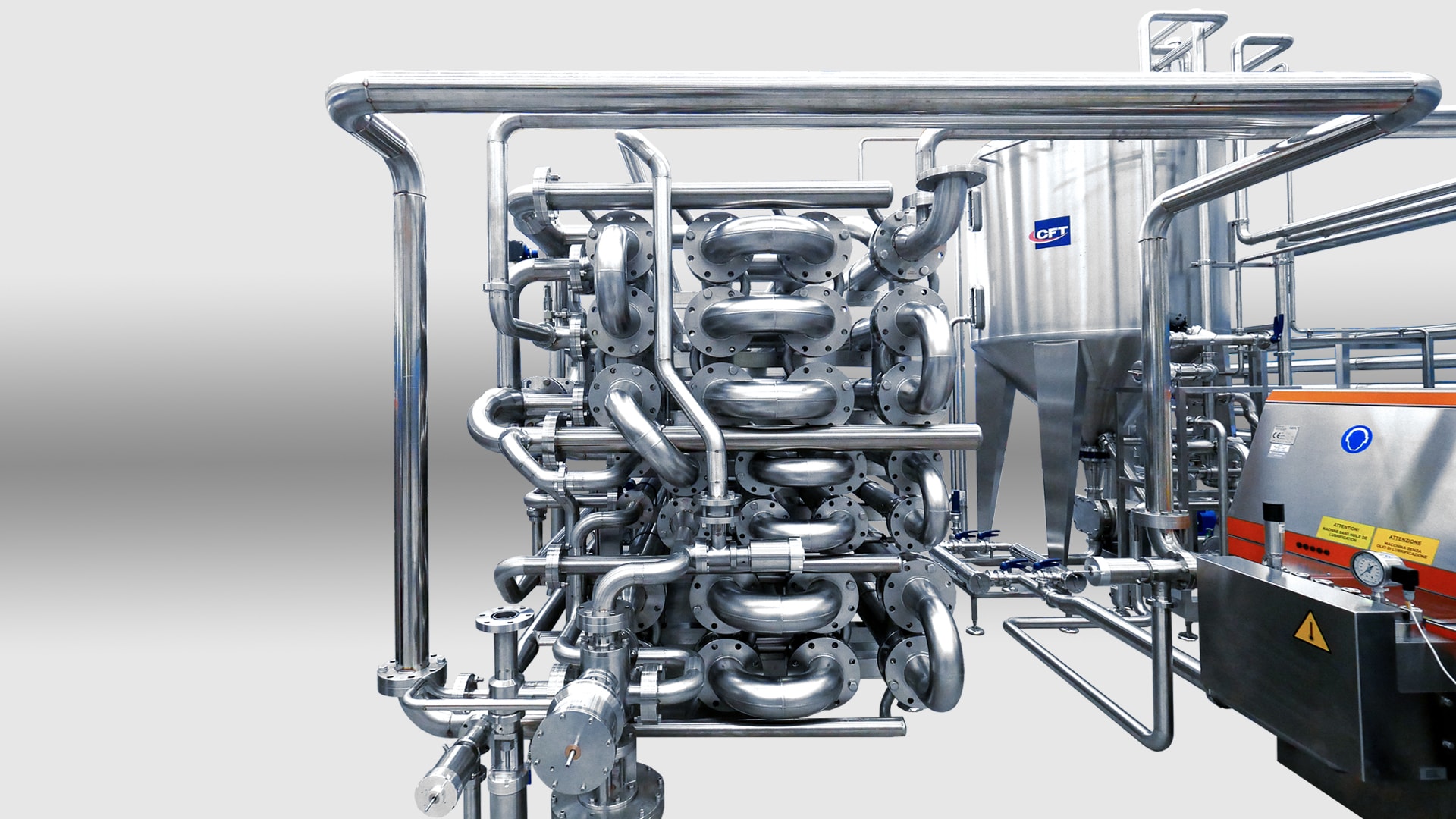

Olimpic TC

High performance and maximum reliability characterize the Olimpic TC sterilizing plant, designed for processing products with high consistency and viscosity values, destined for subsequent aseptic filling.

OVERVIEW

The product is subject to a thermal cycle by means of indirect heat exchangers, concentric pipe type, made of four pipes having decreasing diameters and placed one inside the other. Product flows inside the central annular space, while heating or cooling fluids circulate both inside the internal and external jackets, in counter-current to the product. CFT Group’s patented special flange allows hygienic design and reduced thermal expansions.

This aseptic process allows to preserve product at room temperature over long periods of time, while the whole plant is fully automated.

The plant is normally included in a complete aseptic production line, providing the following processing phases:

- Product sterilization by means of the Olimpic TC plant

- Intermediate aseptic product storage in horizontal or vertical tanks (optional)

- Sterile bag filling by means of an aseptic filler

PRODUCTS: tomato juice, tomato pulp, tomato paste, pizza sauce, ketchup, jams and marmalades, fruit purees and concentrates, soups, baby food

BENEFITS:

- Patented heat exchanger technology, resulting in hygienic design, no stress due to thermal expansion, and fully drainable

- Easy and fast maintenance, with no need for inner bundle full extraction

- Working capacity from 1000 up to 18000 Kg/h

- Maximum thermal exchange efficiency and process uniformity

- Product viscosity up to 10000 cP

- Reduced washing times by means of backflush included in the cycle

The OLIMPIC FT sterilizer and pasteurizer series is designed for sterilizing low and medium viscosity food products such as milk, juices and fruit drinks, concentrated fruit juices and vegetable juices, natural fruit purees, vegetable milks and smoothies.

OVERVIEW

The shell and tube heat exchanger are the core point of this equipment. The tubular heat exchanger guides the product through several straight inner tubes surrounded by a service medium in a shell.

Straight pipes can be corrugated to increase the heat transfer coefficient. Energy savings can be obtained through a system with an intermediate loop product/water/product or by product-to-product tubular exchangers, which guarantees up to 80% energy recovery. The inner bundle of the product-to-product exchangers can be removed for inspecting the product flow path.

Olympic FT can be coupled with all the CFT aseptic fillers. or with CFT piston fillers in pasteurizer version.

PRODUCTS: nectars and clear juices, milk, soy drinks, soft drinks and fruit juices, cooking cream, whipping cream, soy cream, single strength fruit puree

BENEFITS:

- Special design of tanks and heat exchangers to reduce product losses due to the water/product interface

- Energy saving available up to 80%

- Use of positive displacement pumps for mass transfer

- Automatic cycle for descaling all heat exchanger water jackets

- Reduced washing times by means of backflush included in the cycle

- Working capacity up to 40000 l/h

The OLIMPIC SR sterilizer and pasteurizer series scrape surface heat exchangers are a mechanical means of heat transfer for challenging products. CFT Group OLIMPIC SR scraped surface indirect heat exchanger (SSHE), are designed to process very sticky foods or foods which tend to form dregs, containing solid ingredients in pieces, or with high viscosity and consistency.

OVERVIEW

The OLIMPIC SR is composed of a driven rotating cylinder shaft, equipped with scraping blades inserted into an external jacket, in which the heating or cooling fluid circulates. Product runs throughout the space between the rotating shaft and the jacket, while heating and cooling fluids circulate externally, through the jacket, in counter-current to the product. The OLIMPIC SR can be coupled with all the CFT aseptic fillers, or with CFT piston fillers in pasteurizer version.

PRODUCTS: blends of dice tomato and juice, ketchup, jams, blends of dice fruit and juice, soups containing vegetables or ingredients in pieces, baby food containing vegetables or ingredients in pieces, pre-cooked meals, whole and skimmed milk, crystallized whey, blends of milk, sugar, fats, aromas, creams and pharmaceutical products

BENEFITS:

- Different sizes available, with Exchange surface: from 0,86m2 up to 1,5 m2

- Product viscosity: from 100 to 20.000 cP

- Product pressure: up to 20bar

- Sterilizer Frame equipped with 2 hoists to ease the maintenance of seals and blades

- Hygienically designed in accordance with 3-A Sanitary Standards

- SSHE Available in aseptic version, with seals flushed by means of sterile condensate

- Automatic cycle for descaling heat exchangers water jackets.

- WORKING CAPACITY: from 5.000 to 40.000 l/h

The OLIMPIC P series of sterilizers and pasteurizers is manufactured with plate heat exchanger for preheating, pasteurizing and cooling liquid products such as dairy products, beers and other beverages.

OVERVIEW

Olimpic P consists of a unit of corrugated metal plates with openings to allow the two fluids to pass separately through and between the heat exchange plates. The plates are compressed between the fixed frame plate and the movable pressure end plate by mechanical tie rods. The plates have a gasket that seals the channels between the plates and directs the fluids to the alternating channels. The size and number of plates are determined by the flow rate, the physical characteristics of the fluids and the thermal requirements.

PRODUCTS: milk, milk-based and non-milk drinks, concentrated fruit purees, beer, liquid food

BENEFITS:

- Maximum thermal exchange efficiency and process uniformity

- Special design of tanks and heat exchangers to reduce product losses due to the water/product mixing front

- Energy saving available up to 80%

- Automatic cycle for descaling and refining heat exchangers water jackets

- Reduced washing times by means of backflush included in the cycle

- Working capacity from 5.000 to 40.000 L/h

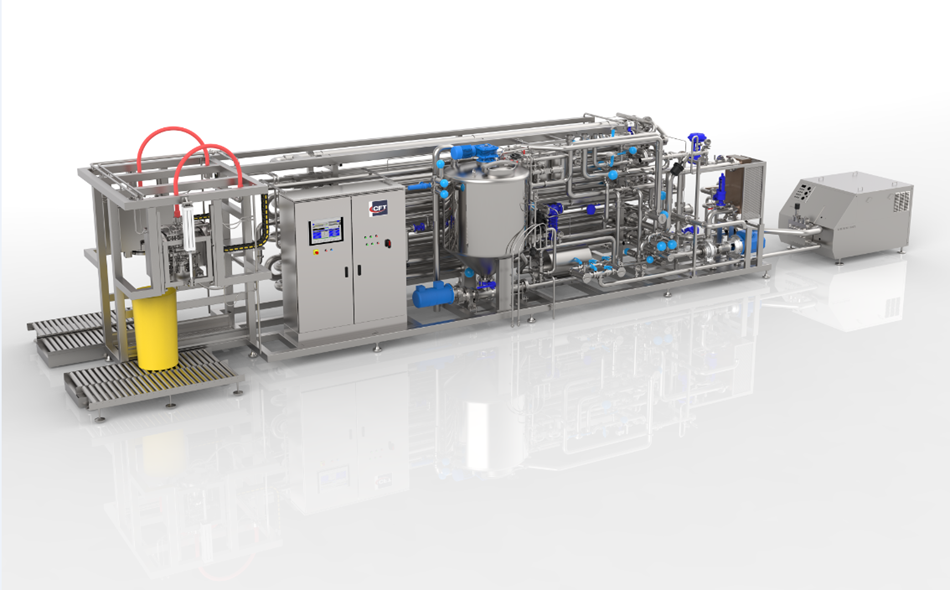

Olimpic CUBE is a series of sterilizers and aseptic fillers, featuring a preassembled turn-key group of aseptic components on a skid requiring little space and time to be installed. The CUBE series is equipped with two aseptic filling heads with the same quality of the Macropak AF/2 (CFT Group’s top range fillers).

PRODUCTS: fruit purees and concentrates, tomato paste, tomato pulp, tropical fruit, vegetables

BENEFITS:

- Patented heat exchanger technology, resulting in HYGIENIC DESIGN, no stress due to thermal expansion and fully drainable

- Capable of processing a wide variety of products and highly viscous ones in particular.

- Capable of filling 220 L bags with a 1” or 2” spouts

- Capable of filling bags from 5 up to 20 kg using the optional kit

- Reduced washing times by means of backflush included in the cycle

- WORKING CAPACITY: 1000-10000 kg/h

An example of CFT Group’s innovation potential and know-how in the UHT sterilization field, Stematic Long Run is, from a technological point of view, one of the most advanced and reliable aseptic processing lines built specifically for the UHT treatment of food and dairy products before the aseptic filling phase.

OVERVIEW

Product is subject to an Aseptic, Thermal and Continuous Process by means of direct steam injection. Product pre-heating and cooling is always designed according to the custom needs of the process and the services available. Each installed line offers the additional benefit of a fully automated control and supervision system.

Strict process tests on pilot plants and research of the most effective solution in the field of milk sterilization ensure excellent performance, premium quality of the finished product and remarkable economic benefits. Stematic Long Run is protected by international patents.

PRODUCTS: milk, milk cream and flavored milk, bechamel, base product for ice-cream, formulated dairy product, soy milk/cream (also flavored), milk/soy-based puddings and desserts, whipping cream

BENEFITS:

- High capacity (up to 40 m3/h).

- Ability to reach very high temperature (over 150°C)

- Ability to process viscous product (Ex. Cream, bechamel,…)

- Short product residence time at the sterilization temperature

- Preservation of the organoleptic and nutritional characteristics of the finished product

- Minimal phenomenon of fouling and fat separation

Ohmic Series

Thermal treatment is an essential step in all production processes that have the goal to destroy micro-organisms by the application of heat. The OHMIC technology is the fastest and most gentle technique to heat food, for products containing particles, thus preserving the integrity and the physical characteristics of your product.

OVERVIEW

The OHMIC HEATER is the core of a complex system whose main components are:

- buffer tank specifically designed to mix particulate and liquid;

- special design double piston pump equipped with ball valves on suction and delivery sides, specifically designed for products with pieces,

- feeds the sterilizer-cooler with low product pulsation;

- ohmic heating modules

- divert valve;

- aseptic cooler;

- aseptic buffer tank

We have developed a range of ohmic heaters with operating characteristics that exceed the performances traditionally guaranteed by other heaters available on the market. This ohmic system offers high efficiency with a total performance above 97%.

PRODUCTS: fruits & vegetables in all forms, iqf products, wild berries, mushrooms, fruit or vegetable juices with / without particles, soups, ready meals, sauces (with large and small particles – velvety & moulinè), smooth sauces, jams with particles.

BENeFITS:

- extremely versatile as it heats any type of food.

- In case of A mechanical fault, voltage WILL BE cut out to guarantee high level of safety for the operator and the electrical equipment.

- Power is read at the source, THUS ENSURING AN optimized management of consumption and setting of the heating temperature.

- The heater is supplied with an automatic system that switches voltage when the product conductivity changes.

- management system is designed for the operator to set, edit and control the operating parameters in a user-friendly and intuitive WAY.

Aseptic Flash Cooler

Our Aseptic Flash cooler sterilizer series guarantees the highest processing safety and best product quality. Extremely simple to install and operate, this is the best choice when large production capacities of high viscosity product to be sterilized and cooled continuously is required. The product is quickly heated through direct steam injection, then briefly stored in a hot holding tank and finally instantly cooled in a flash tank kept in high vacuum condition.

PRODUCTS: tomato paste

BENEFITS:

- Efficient working capacity up to 40000 kg/h

- Capability to process very high viscosity products with final Bostwick < 2

- Long running cycle unattainable with other types of sterilizers

- self-adjusting parameters based on incoming flow rate

- Flow rate is automatically adjusted to maintain a constant product level in the buffer tank.

- Full monitoring of the process and possibility to record data