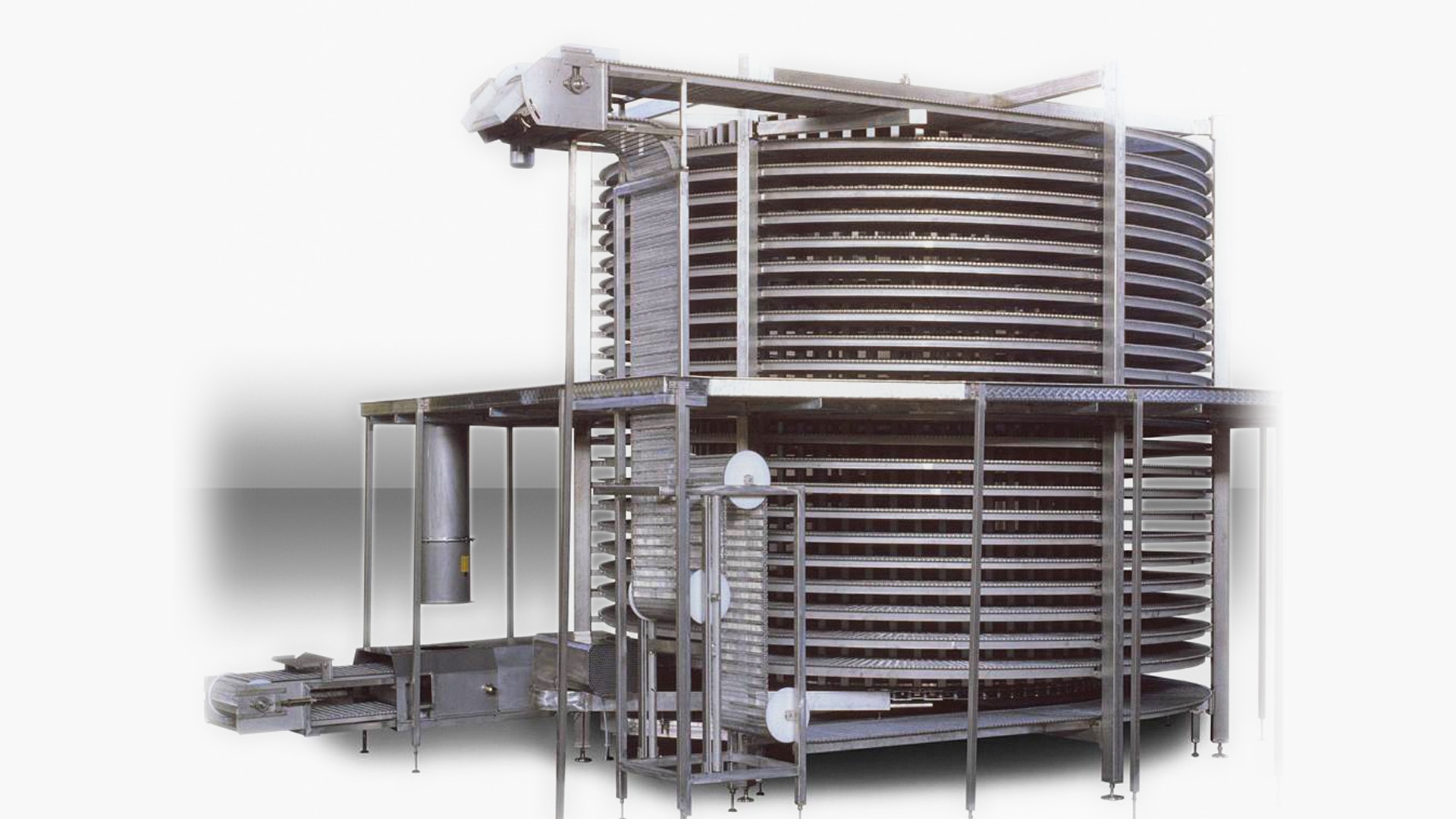

Spirals

Complete range of spirals for pasteurization, cooling, refrigeration, cooking and drying for non-packaged and packaged food products.

The packaged product to be thermally-treated is placed on a flexible belt where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to a series of special water jets, hitting the product from the top and bottom.

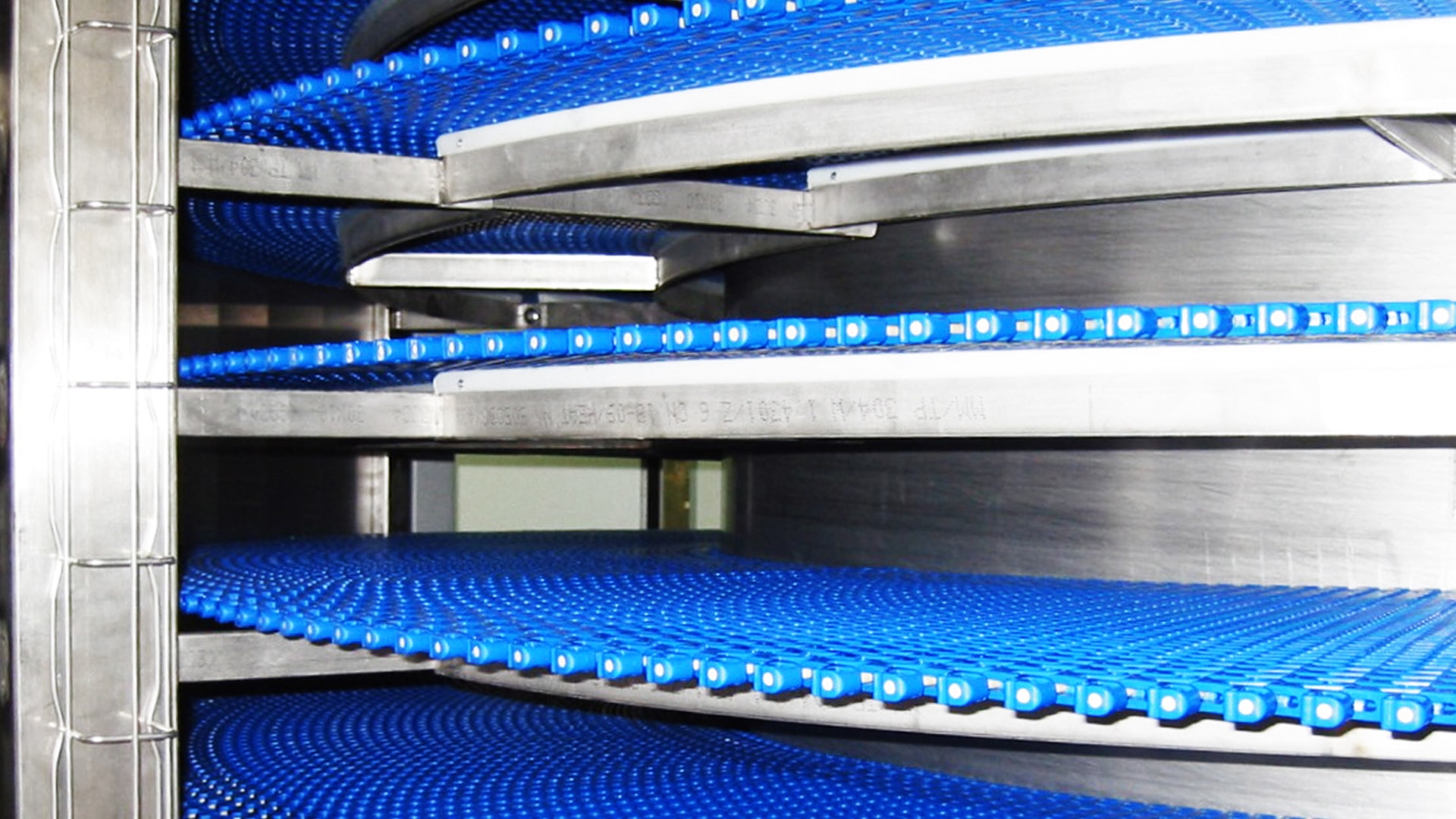

A water recovery and circulation system ensure limited water consumption. The belt drive is based on a simple and reliable central drum system, operating with low-tension. Each standard spiral system can be set-up individually to match customer needs, requirements and technical specifications.

Spirafreeze SFC

The product to be frozen is placed on a flexible belt, either orderly or randomly, where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to an intense flow of chilled air.

OVERVIEW

The belt drive is based on a simple and reliable central drum system and requires low tensioning for correct operation. The dwell time/speed of the belt is regulated with frequency variators.

The horizontal air circulation system combined with evaporators of the flat-fin, decreasing-spacing type, ensures temperature uniformity and low energy consumption.

The whole system is enclosed within an insulated cabin.

The SPIRAFREEZE SFC is available in 6 standard configurations and 4 standard tier pitches.

PRODUCTS: non packaged solid medium- to large-size products, fed in bulk or in an orderly way: vegetables, fruits, meat, fish, oven products, pizzas, etc, non packaged soft medium- to large-size products thanks to optional tangential feeders, packaged products: trays, pouches, cups containing solid, liquid or solid-liquid mixes such as ready-made dishes, ice-creams, etc.

BENEFITS:

- Quick installation, possibility to move the unit easily

- No possibility of product contamination thanks to the lubrication-free conveyor system

- High mechanical reliability and stability

- Reduced belt wear and elongation thanks to the drive system requiring low tensioning

- No belt flipping thanks to proprietary software for automatic adjustment of belt

- spirals and drums are made of stainless steel

- Circulation fans placed in dry zone (without clogging)

- Long work cycles due to evaporators with large and decreasing fin-spacing. No frost-blowing systems required for most applications

- Low cost of spare parts and maintenance activities due to high quality components

- WORKING CAPACITY: from 400 up to 800 KG/h

The product to be frozen is placed on a flexible belt, either orderly or randomly, where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to an intense flow of chilled air.

OVERVIEW

The belt drive is based on a simple and reliable central drum system and requires low tensioning for correct operation. The dwell time/speed of the belt is regulated with frequency variators.

The horizontal air circulation system combined with evaporators of the flat-fin, decreasing-spacing type, ensures temperature uniformity and low energy consumption.

The whole system is enclosed within an insulated cabin.

Each standard SPIRAFREEZE system can be individually configured to match customer needs and specifications.

PRODUCTS: non packaged solid medium- to large-size products, fed in bulk or in an orderly way: vegetables, fruits, meat, fish, oven products, pizzas, etc, non packaged soft medium- to large-size products thanks to optional tangential feeders, packaged products: trays, pouches, cups containing solid, liquid or solid-liquid mixes such as ready-made dishes, ice-creams, etc.

BENEFITS:

- No possibility of product contamination thanks to the lubrication-free conveyor system

- High mechanical reliability and stability

- Reduced belt wear and elongation thanks to the drive system requiring low tensioning

- No belt flipping thanks to proprietary software for automatic adjustment of belt tension

- spirals and drum are made of stainless steel

- Low electric consumption thanks to horizontal air flow and evaporators with extra-large fin spacing

- Circulation fans placed in dry zone (without clogging)

- Long work-cycles due to evaporators with large and decreasing fin-spacing. No frost-blowing systems required for most applications

- Low cost of spare parts and maintenance activities due to high quality components

- WORKING CAPACITY: from 400 to 8,000 KG/h

Mecspray MS-R / Mecspray MS-P

MECSPRAY MS-P is a spiral pasteurizers' range working with water jets.

The packaged product to be thermally-treated is orderly placed on a flexible belt where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to a series of special water jets, hitting the product from the top and bottom. A water recovery and circulation system ensures limited water consumption.

OVERVIEW

The belt drive is based on a simple and reliable central drum system, operating with low-tension. The dwell time/speed of the belt is regulated with frequency variators.

The whole system is enclosed within a protection cabin (coolers) or insulated protection cabin (pasteurizers).

Each standard MECSPRAY MS-R and MS-P system can be individually configured to match customer needs and specifications.

PRODUCTS: hot-filled products packaged in flexible or rigid containers: fruit juices, fruit purees, tomato based sauces, etc, food products packaged in flexible or rigid containers: diced fruits in heavy syrup, tomato sauces with pieces, etc.

BENEFITS:

- Special nozzles (proprietary design) obtain product stirring, increase thermal exchange/production capacity and reduce electric energy consumption

- No possibility of product contamination thanks to lubrication-free conveyor system

- High mechanical reliability and stability of spiral conveyor

- Reduced belt wear and elongation thanks to the drive system requiring low tensioning

- No belt flipping tanks to proprietary software for automatic adjustment of belt tension

- All water piping and spiral structures, including drum, made of stainless steel

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- WORKING CAPACITY: from 400 to 10,000 KG/h

Mecair MA-R / Mecair MA-P

The product to be thermally-treated is placed on a flexible belt, either orderly or randomly, where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to a strong flow of cold/hot air. Frequently, the heat treatment is followed by a cooling phase.

OVERVIEW

The belt drive is based on a simple and reliable central drum system and requires low tensioning for correct operation. The dwell time/speed of the belt is regulated with frequency variators.

A special horizontal air circulation system ensures a high degree of temperature uniformity across the belt.

The whole system is enclosed within an insulated cabin.

Each standard MECAIR MA-C and MA-P system can be individually configured to match customer needs and specifications.

PRODUCTS: non-packaged solid products fed in bulk or in rows, packaged products: solid, liquid or mixes, pasteurizing and cooling of food products packaged in flexible or rigid containers (packaged fresh noodle, packaged sausages, etc.)

BENEFITS:

- No possibility of product contamination thanks to lubrication-free conveyor system

- High mechanical reliability and stability of spiral conveyor.

- Reduced belt wear and elongation thanks to the drive system requiring low tensioning

- No belt flipping thanks to proprietary software for automatic adjustment of belt tension

- All spiral structures, including drum, made of stainless steel

- Low electric consumption thanks to horizontal air flow and evaporators with extra-large fin spacing (coolers)

- Circulation fans placed in dry zone for minimisation of clogging (coolers)

- WORKING CAPACITY: from 400 to 3.000 KG/h

Mecair MA-C Spiral cookers

The product to be cooked is placed on a flexible belt, either orderly or randomly, where the product remains motionless. The belt runs a spiral-shaped path where the product is subjected to a suitable flow of hot air.

OVERVIEW

Cooking can be made in a:

- humid environment obtained with direct steam injection;

- dry environment obtained with dry hot air make-up.

Both cooking types feature automatic humidity control.

A special horizontal air circulation system ensures a high degree of temperature uniformity across the belt.

The belt drive is based on a simple and reliable central drum system and requires low tensioning for correct operation. The dwell time/speed of the belt is regulated with frequency variators.

The whole system is enclosed within an insulated cabin.

Each standard MECAIR MA-C system can be individually configured to match customer needs and specifications.

PRODUCTS: non packaged solid products fed in bulk or in rows (sausages, etc.)

BENEFITS:

- No possibility of product contamination thanks to lubrication-free conveyor system

- High mechanical reliability and stability of spiral conveyor

- Reduced belt wear and elongation thanks to the drive system requiring low tensioning

- No belt flipping thanks to proprietary software for automatic adjustment of belt tension

- All spiral structures, including drum, made of stainless steel

- A special horizontal air circulation system ensures a high degree of temperature uniformity in all belt lanes

- Low cost of spare parts and maintenance activities due to utilization of high quality commercial components

- WORKING CAPACITY from 400 to 2000 KG/h