Sorting Machines

Optical sorters with high or very high-resolution cameras, equipped with different technologies depending on the physiognomy of the target product.

Raytec’s optical sorting machines can be successfully adopted for many kinds of food such as tomatoes, fresh-cut lettuce, frozen fruit and vegetables, preserved fruit and vegetables, tubers, snacks and dried products, seafood, wine, confectionery and pasta. Raytec’s technology is constantly evolving and can guarantee an ultra-clean design complying with EHEDG standards, as well as the removing of defects and foreign bodies of any kind.

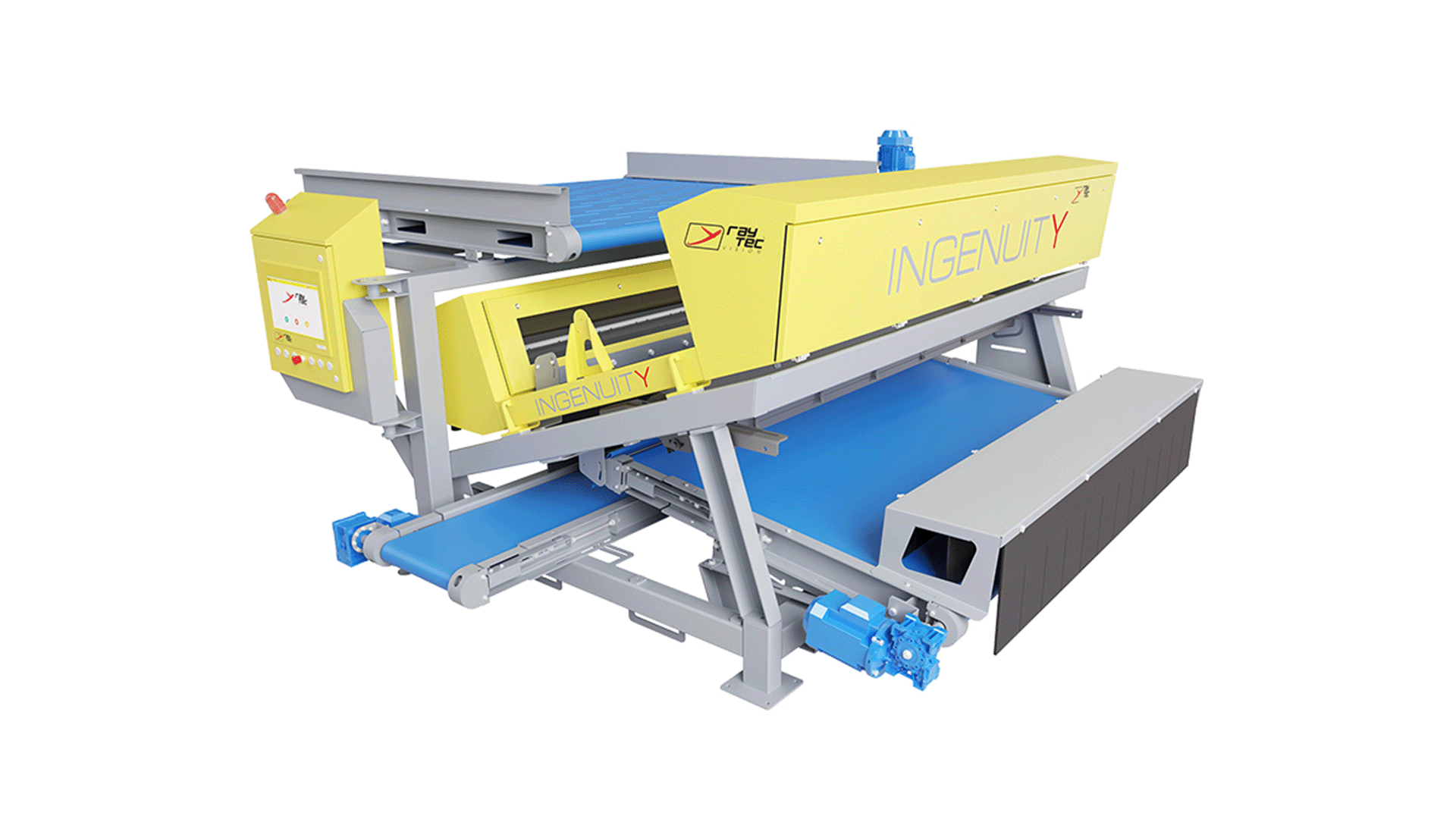

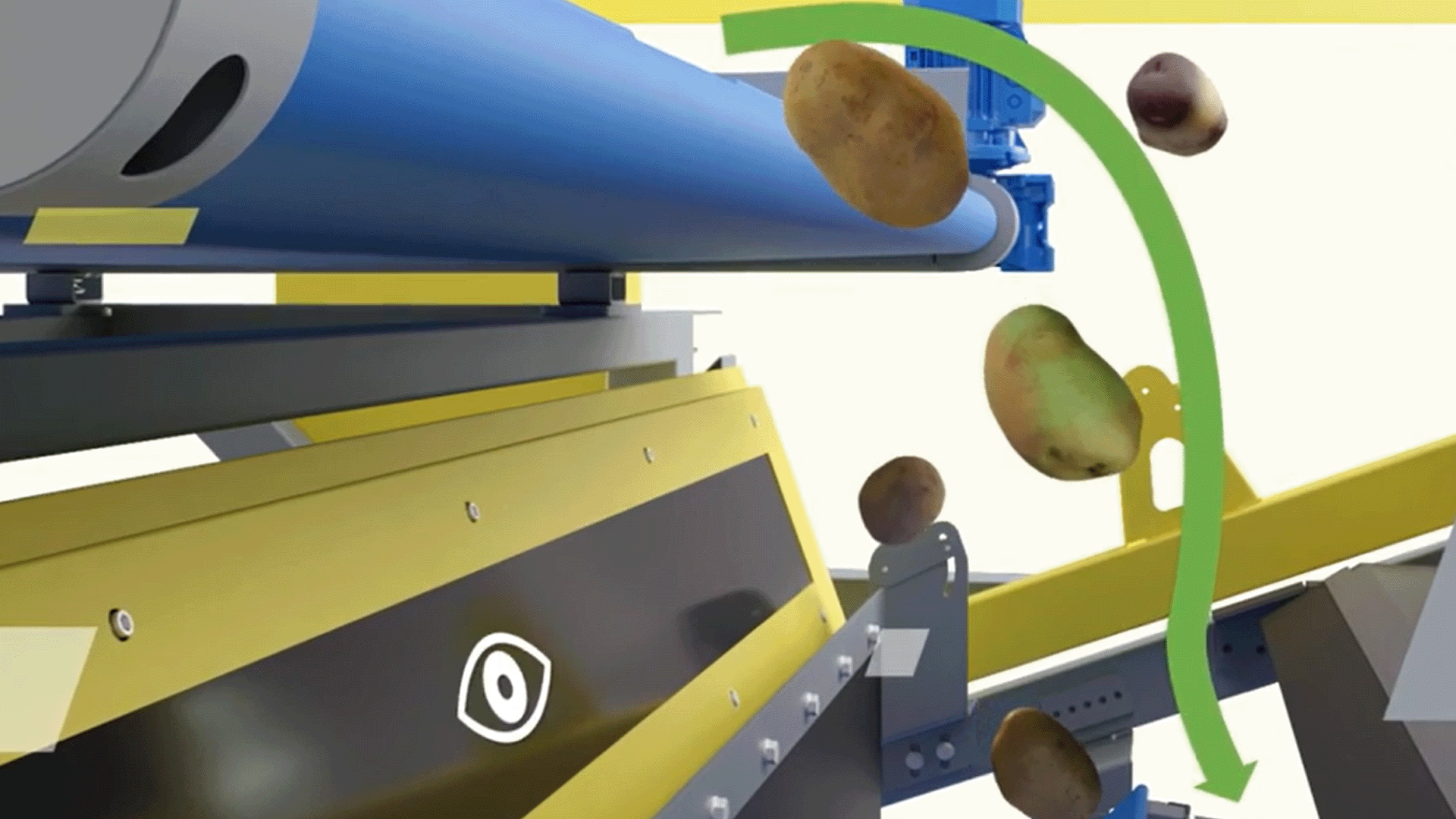

Ingenuity is a double-vision sensor sorter. It is equipped with Visible Color and NIR technology (Near Infra Red).

The system can detect organic or inorganic foreign bodies (including completely black), rotten products and color defects. Thanks to the 100 channels configuration, it allows a capacity up to 80 t/h, for a large agro and industrial production.

The machine is available in a 2WAY configuration and the ejection system is by mechanical fingers in a special high-resistance and anti-abrasion material.

Products: washed and unwashed potatoes, apples and onions.

Benefits

- High production capacity

- Low maintenance

- Constant selection over time

- Detection in real time

- Automatic capture of images

- User-friendly software

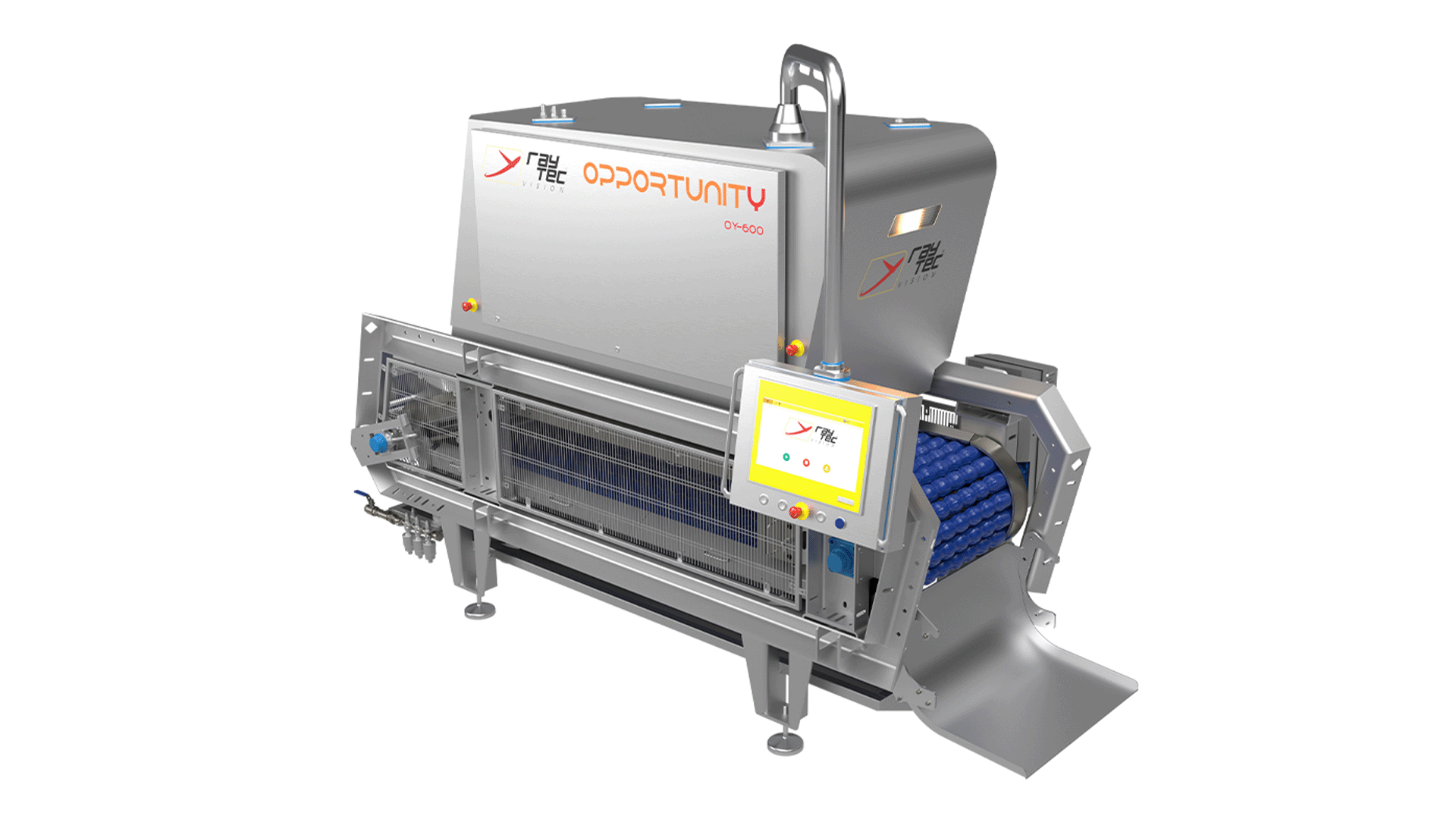

Opportunity

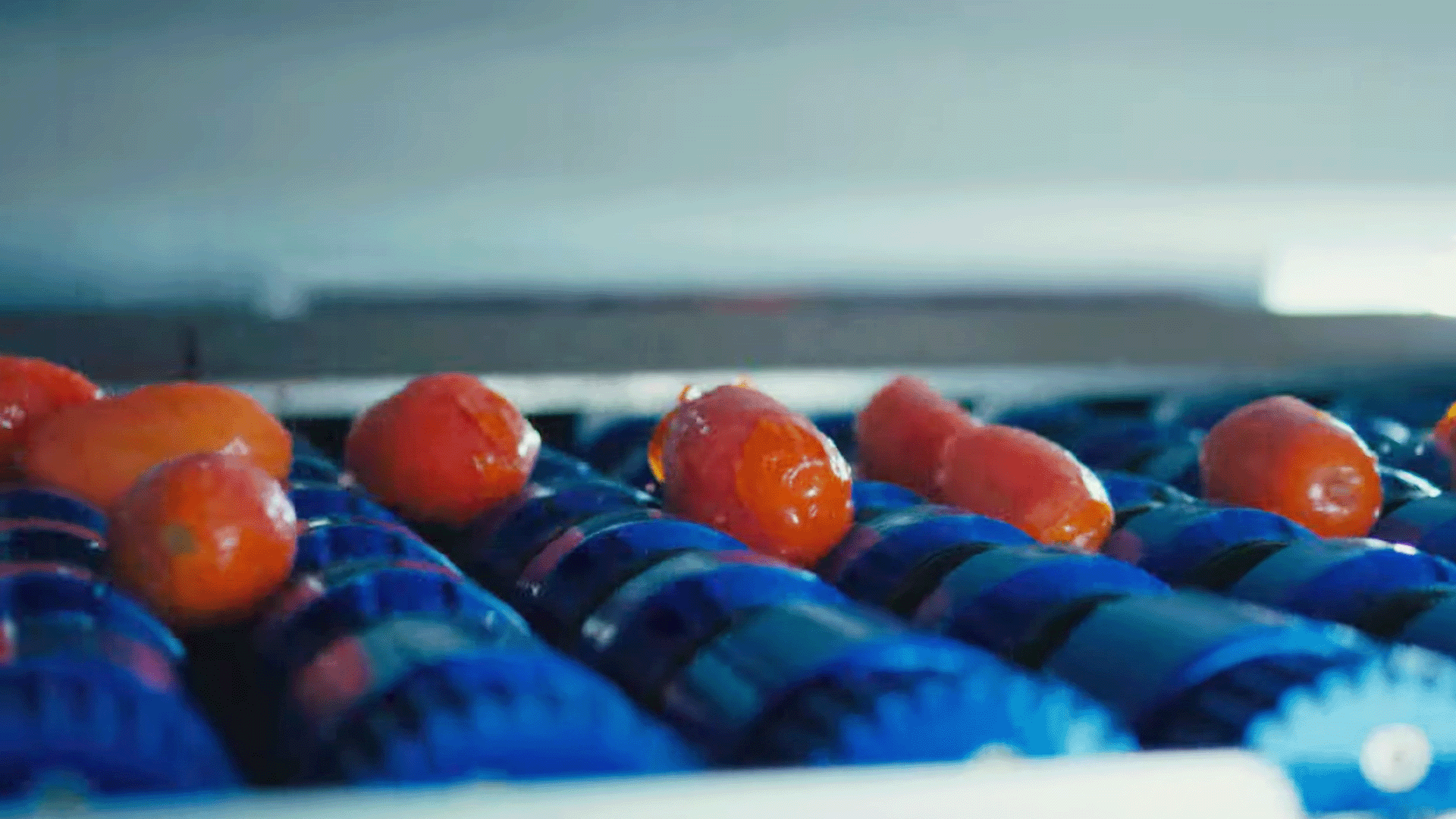

Opportunity is an optical food sorter which exploits artificial intelligence (Deep Learning) for 360-degree product quality control. Thanks to the roller belt (spin belt) that allows products to rotate and matrix cameras to capture entire frames of the rolling product, the software enables increased product quality, completely replacing manual sorting.

Overview

Opportunity is based on the principle of self-learning and can be adapted to the selection of different types of products. With its compact design and ability to communicate with other machines, it can be easily placed within processing lines to contribute to complete production automation.

This optical sorting machine is capable of performing a real-time “identikit” of each product, on each side. This enables to identify even the slightest defect. The great advantage of artificial intelligence is that the machine is “trained” with the acquisition of many images and easily adapts to the growing needs of quality control.

Products: potatoes and tomatoes.

Benefits

- High production capacity. Enables selection of large quantities of product in little time

- Low maintenance

- Constant selection over time

- Detection in real time

- Automatic capture of images

- User-friendly software

Curiosity

CURIOSITY is the first optical sorting machine born to achieve the totally hygienic compliance according to the EHEDG guidelines. This sorting machine combines innovation, essential design and latest vision technology, it perfectly meets the needs of safety and quality control, hygienic operation, easy and quick sanitation.

Overview

Curiosity’s new design allows to match the high efficiency, typical of Raytec Vision sorters, together with the latest request of high standards of hygiene and easy cleaning. Managed by Raytec Vision powerful UNYCO software, Curiosity can detect all defects and inclusions that you seek to reject, while taking care of your production.

UNYCO is the intuitive and user-friendly software that allows the user to set recipes on the Curiosity sorter, according to the product to be selected.

It allows the detection of:

- Color alterations

- Caliber

- Foreign bodies

- Shape

- Stem

It also performs statistical analysis relating to the quantity of objects processed, the quantity of compliant products and that of non-compliant products divided by the type of defect and waste output.

PRODUCTS: fruits and vegetables

BENEFITs:

- High production capacity

- Significant labour savings (up to 100% according to application)

- High levels of Quality and Safety of products selected

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time

- Maintenance of high standards of hygiene thanks to the totally hygienic design

- Low maintenance costs

- User-friendly software for easy use and programming

Dryce

Dryce can dispose of colour defects, rotten produce and foreign bodies also if they are of the same colour as the good product. A vibratory shaker built in the machine conveys the product to a vertical chute ensuring a consistent trajectory.

OVERVIEW

Dryce is available in two versions:

DR-602:

- 600 mm vision width

- 96 ejection valves

DR-1202:

- 1200 mm vision width

- 192 ejection valves

Both models can be equipped with 3Way ejection system. They can have two reject systems on board to differentiate unusable produce from second quality.

PRODUCTS: dried food products, frozen food products

BENEFITS:

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application).

- High levels of Quality and Safety of products selected not achievable through labour

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Maintenance of high standards of hygiene thanks to the original ultra-clean design

- Low maintenance costs

- User-friendly software for easy use and programming

Discovery is an optical sorter with a very high resolution camera which inspects the product on the conveyor belt and is designed to check fruits and vegetables, both whole and chopped.

OVERVIEW

Any defects that these products might have (colour, foreign bodies, rotten parts) are detected by Discovery thanks to an accurate analysis. The product is fed onto the inspection belt, which is designed to stabilise the product to prevent it from rolling about during scanning. The vision area and the ejection area are well-separated in order to avoid product splashes, so as to guarantee impeccable selection, even over prolonged periods.

This optical sorter can be equipped with just one ejection air-jet system with 288 electrically operated ejector valves or, in the 3Way option, with two reject systems in order to differentiate a second product quality level.

PRODUCTS: baby lettuce, lettuce, spinach, cut carrots, cut potatoes, sweetcorn, peas, rehydrated beans, whole and cut beans, cut peppers, broccoli, diced onions, peeled garlic, potato chips and french-fries, olives, diced peaches, diced pears, grapes, dried prunes, dried apricots, dried cherries, dates, frozen berries, strawberries, frozen cherries, mussels, sea salt

BENEFITS:

- High production capacity: large quantities of product can be selected in a very reduced time

- Significant labour reduction (up to 100% depending on the application).

- High levels of product Quality and Safety which cannot be achieved with the use of labour

- Reading of the qualitative and quantitative data of the raw materials analysed in real time

- Automatic capturing and filing of the images of the rejected products for post-production analysis

- Selection constant over time, even over 3 work shifts

- Low maintenance costs

- User-friendly software for ease of use and programming

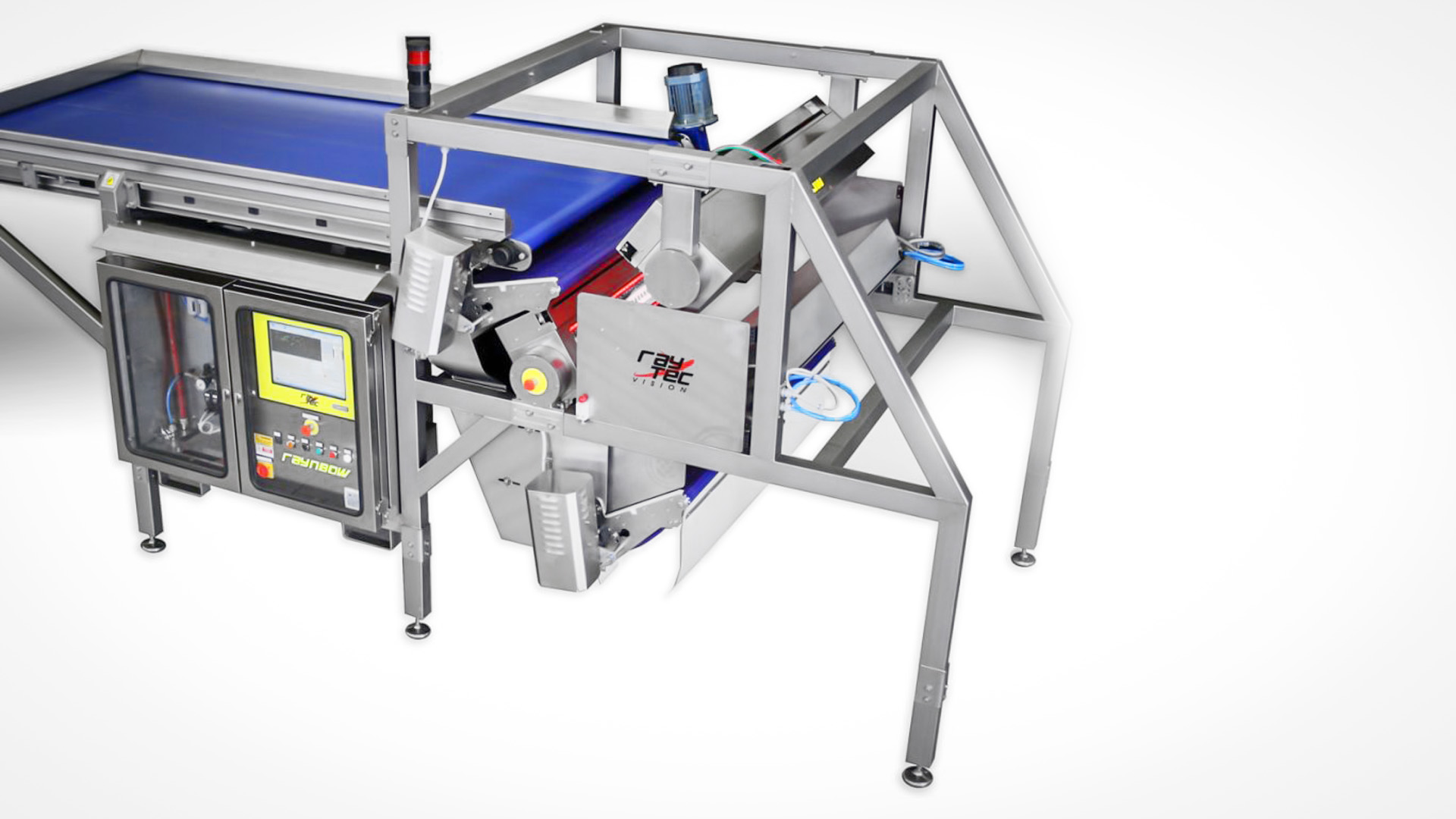

RAYNBOW is a sensor-based high resolution optical sorter with the power to scan 100% of the processable products (fruit and vegetables) thanks to its “instant double vision” system.

OVERVIEW

This technology, which has been made possible by high resolution optics has the power to reject colour defects, foreign bodies of the same colour as the product being processed and products that can no longer be processed because they are rotten.

The conveyor belt fitted at the infeed to the Raynbow is designed to stabilise the fruit or vegetables to be processed, so that they can be properly inspected and, if necessary, ejected. In this way, the products arrive both at the vision area and at the ejection area in the correct position.

The Raynbow sorter can be fitted with two ejection systems: an electro-pneumatically-operated blade reject system or an electrically-operated air-jet ejection system. In the 3Way option, the machine can be fitted with two reject systems which differentiate unusable defects from defects considered as a second product quality level.

PRODUCTS: fruits, vegetables

BENEFITS:

- High production capacity: large quantities of product can be selected in a short time

- Significant labour reduction (up to 100% depending on the application)

- Reading of the qualitative and quantitative data of the raw materials analysed in real time

- Automatic capturing and filing of the images of the rejected products for post-production analysis

- Selection constant over time, even over 3 work shifts

- Low maintenance costs

- User-friendly software for ease of use and programming

SPRAY is an optical sorter with a very high-resolution camera designed to check products such as whole or cut vegetables and fruit.

Overview

The selection criteria are managed through a special software program in which the machine calibration data are entered, so as to obtain a tailor-made sorting recipe allowing to reject defects and contaminants as desired (i.e. colour defects, rotten products and foreign bodies, even of the same colour as the good product).

PRODUCTS: baby lettuce, cut peppers, broccoli, diced onions, peeled garlic, potato chips and french-fries, olives, diced peaches, diced pears, grapes, lettuce, spinach, cut carrots, cut potatoes, sweetcorn, peas, rehydrated beans, whole and cut beans, dried prunes, dried apricots, dried cherries, dates, frozen berries, strawberries, frozen cherries, mussels, sea salt

BENEFITS:

- High production capacity. Large quantities of product can be selected in a short time

- Significant labour reduction (up to 100% depending on the application).

- High levels of product Quality and Safety which cannot be achieved with the use of labour

- Reading of the qualitative and quantitative data of the raw materials analysed in real time

- Automatic capturing and filing of the images of the rejected products for post-production analysis

- Selection constant over time, even over 3 work shifts

- Low maintenance costs

- User-friendly software for ease of use and programming

RAYVOLUTION is an optical sorter with a very high resolution camera designed to check all kinds of industrial tomatoes (peeled and unpeeled).

Overview

This type of optical sorter has the power to reject colour defects, rotten tomatoes and foreign bodies, even of the same colour as the product to be subsequently processed. The product is fed onto the inspection belt which is designed to stabilise the tomatoes to prevent them from rolling around while they are being checked: the vision area is well-separated from the ejection area in order to prevent splashes of product from jeopardising selection over the course of time.

PRODUCTS: all kinds of industrial tomatoes (peeled and unpeeled).

BENEFITS:

- High production capacity: large quantities of product can be selected in a short time

- Significant labour reduction (up to 100% depending on the application).

- High levels of product Quality and Safety which cannot be achieved with the use of labour

- Automatic capturing and filing of the images of the rejected products for post-production analysis

- Selection constant over time, even over 3 work shifts

- Low maintenance costs

- User-friendly software for ease of use and programming

Typhoon is an optical sorter that fits sophisticated, very high resolution cameras with the power to detect defects, foreign bodies in the processed product and eliminate them immediately.

OVERVIEW

With the Typhoon management system, the types of defects to be rejected can be checked and changed: colour, products that are no longer usable and foreign bodies, even of the same colour as the good product.

The product to be selected is fed onto the inspection belt forming a thin layer and the vision area is well-separated from the ejection area in order to prevent splashes of product from jeopardising selection over the course of time.

Typhoon may be equipped with just one ejection system or, alternatively, with two of them for the selecting of both fine pulp and diced tomatoes. The main ejection system installed on Typhoon operates with the use of nozzles which create a vacuum in the area containing the defect; the machine can mount up to 176 suction nozzles, the diameters of which vary according to the product particle size (from a minimum of 8 mm to a maximum of 25 mm).

PRODUCTS: liquid or pulpy food products such as: fruit puree, tomato puree, extruded tomato pulp or pulpy, diced fruit, diced tomatoes

BENEFITS:

- High production capacity. Large quantities of product can be selected in a short time

- High levels of product Quality and Safety which cannot be achieved with the use of labour

- Possibility to process highly contaminated products, restoring a commercial value to them

- Automatic capturing and filing of the images of the rejected products for post-production analysis

- Selection constant over time, even over 3 work shifts

- Low maintenance costs

- User-friendly software for ease of use and programming

Dionysos

Dionysos is equipped with a multifrequency pulsed LED lighting system allowing to overcome the limits of the laser. This is made possible by the BLUEIGHT technology, a package of functions based on 8 different processed images obtained by pulsing in a sequence different lights. By this technology it won’t be necessary to install a different color belt to identify the items, or to sort them by flying on rotating luminous backgrounds.

OVERVIEW

Powered by the BLUEIGHT technology it removes all contaminants such as rotten grapes, stalks, leaves and, if requested, green grapes, any type of plastic, irrespective of the color, any kind of insect, dry grapes even if they have the same color of the good ones. By the Double Rejection System (air jet + air jet) the DIONYSOS can be configured as a 3WAY sorter, to reject on a separate stream the dry grapes, usually addressed to 2nd quality wines. Avoiding the 2nd late fermentation due to the dry grapes this sorter helps in keeping the sugar level under control.

PRODUCTS: grapes

BENEFITS:

- It captures images directly by the stream and check the adjustment’s results by the graphic interface

- It analyzes the defects by means of HSL color analysis

- It checks the chlorophyll content

- It rejects by size (BLOB) and shape

- The machine stops in case of animal detection (or a part of it)

- It is able to detect transparent glass or plastic reject grapes with stem

Rayfly is an optical sorting machine with high resolution sensors that examine the product using the “high speed double vision system” to analyze 100% of the surface of each product. The system is used to check first and fourth range baby-leaf lettuce and pre-selection of green beans.

Overview

The machine can dispose of foreign bodies also the same colour as the good product. The product is fed on a tilted conveyor belt used to bring the product to the vision zone. By doing so, all the products can be inspected and, if necessary, ejected on presenting the same conditions in both the vision zone and the reject zone.

Rayfly is equipped with a palette waste reject system with electro-pneumatic drive.

PRODUCTS: baby-leaf lettuce, green beans

BENEFITS:

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application)

- The 4th range lines preserve the clean wash water by avoiding contact with pollutant contaminants

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time, also over 3 work shifts

- Low maintenance costs

- User-friendly for easy use and programming