CFT Group provides single machines and complete turnkey lines for the Beverage Processing and Filling Industry, especially for soft drinks production. This represents a strong benefit for the final customer, since most of the equipment is manufactured inside our headquarters, allowing CFT Group to be a single trustworthy partner throughout all the project stages.

PROCESSING RANGE

Syrup Rooms

Complete Syrup Rooms available from 3.000 to 60.000 It/hour of final product in automatic or semiautomatic version. Starting from semi processed materials (like sugar and compounds) to final drinks. The capacity to develop customized & tailored syrup rooms according to the existing “on-factory” situation is one of our best ability.

Flash Pasteurizers

Product pasteurizers are available either with tubular or plate heat-exchangers for carbonated products such as energy drinks and for limpid and fibers-containing products. Several of these machines have been installed into a hot fill package, considering features like product recirculation, de-aeration system with aroma recovery, homogenization.

Mixers and Saturators

Mixing and carbonating units are the most common machines installed close to a filler. Our range includes three different types of machines available:

- The Mixers “Sym Mix Series”, which mix flavoured syrup with water to produce flat drinks in a quantity ranging from 5,000 to 60,000 litres per hour.

- The Carbonators “Sym Car Series”, which mix water or ready-mixed still drinks with CO2 to produce a final carbonated product in an amount ranging from 5,000 to 60,000 litres per hour.

- The Mixers – Carbonators “Sym Car Mix Series”, which mix flavoured syrup with water and CO2 to produce final CSD product in an amount ranging from 5,000 to 60,000 litres per hour.

These machines provide ultra-quick product changeover, high performances and compact design. A complete range of optional equipment is available to satisfy the most demanding requests.

Tunnel Pasteurizers

We supply premium tunnel pasteurizers equipped with an automatic system which allows to avoid the over-pasteurization of the product in case of stop of the internal conveyor.

CIP systems

We provide special CIP units to sanitize the plants allowing the complete cleaning and disinfection of the machines. Different washing programs (product change, end of the day, weekends) are saved in the PLC. Additional programs can be easily added.

Example of a syrup room for soft drinks

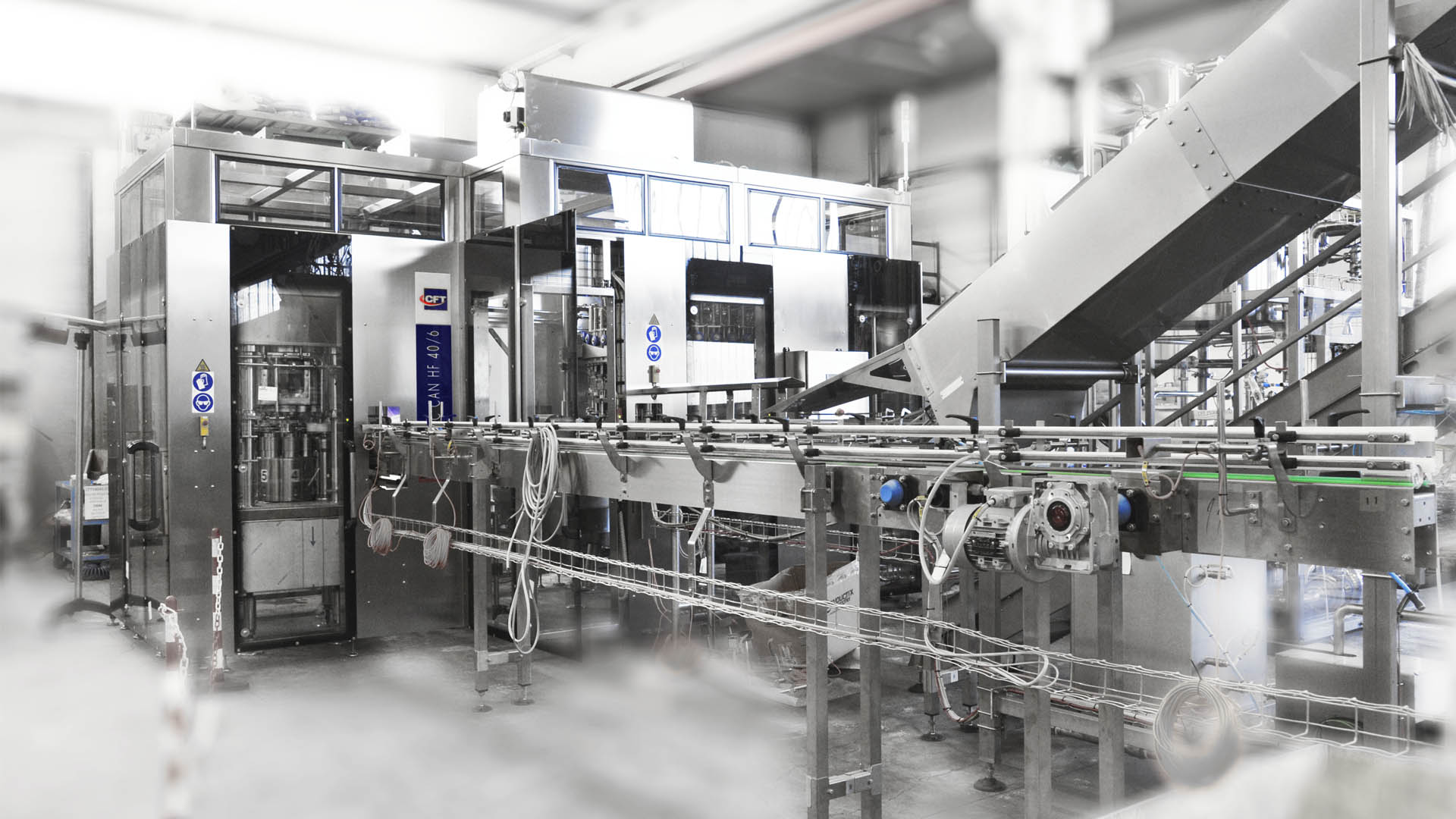

Filling range

We design and manufacture complete bottling and canning lines for still or carbonated beverages and water in cans, glass or PET bottles. 1.3 million bottles per day are filled by our turn-key lines and plants.

The filling speed goes from 3,000 to 80,000 containers per hour, depending on the containers type.

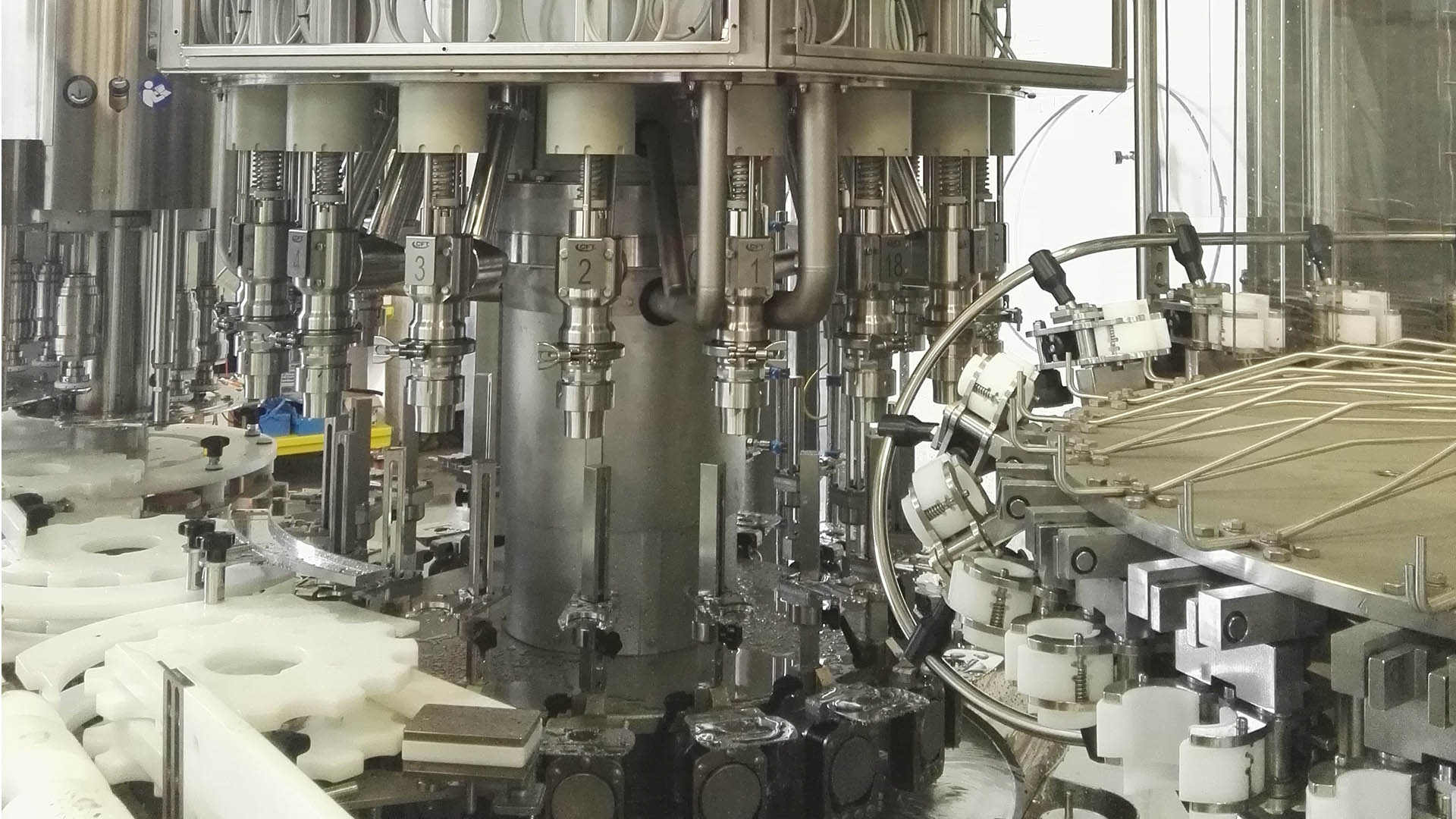

Our can filling lines have the following common features:

- Filling speed from 3,000 up to 80,000 cph

- Highly compact: downsized footprint while maintaining very high production standard

- Fully electronic: high degree of automation thanks to the plug and play system

- Highly precise: great filling accuracy

Our bottle filling lines have the following common features:

- Extremely fast changeover (product/bottle) design

- Very low costs of management and maintenance

- User friendly operator panel with touch controls and auto-diagnostic software.