Receiving, washing, sorting systems

Modular receiving and washing systems for fruits and vegetables. Different configurations are available depending on the specific customer’s needs and plant’s layout.

All our complete lines are equipped with accurate receiving and washing integrated systems which allow the ingredients to reach the processing phase, where raw materials are turned into final product ready to be filled. This final stage can be reached only after a careful selection of the raw ingredients (fruits or vegetables) entering the processing line.

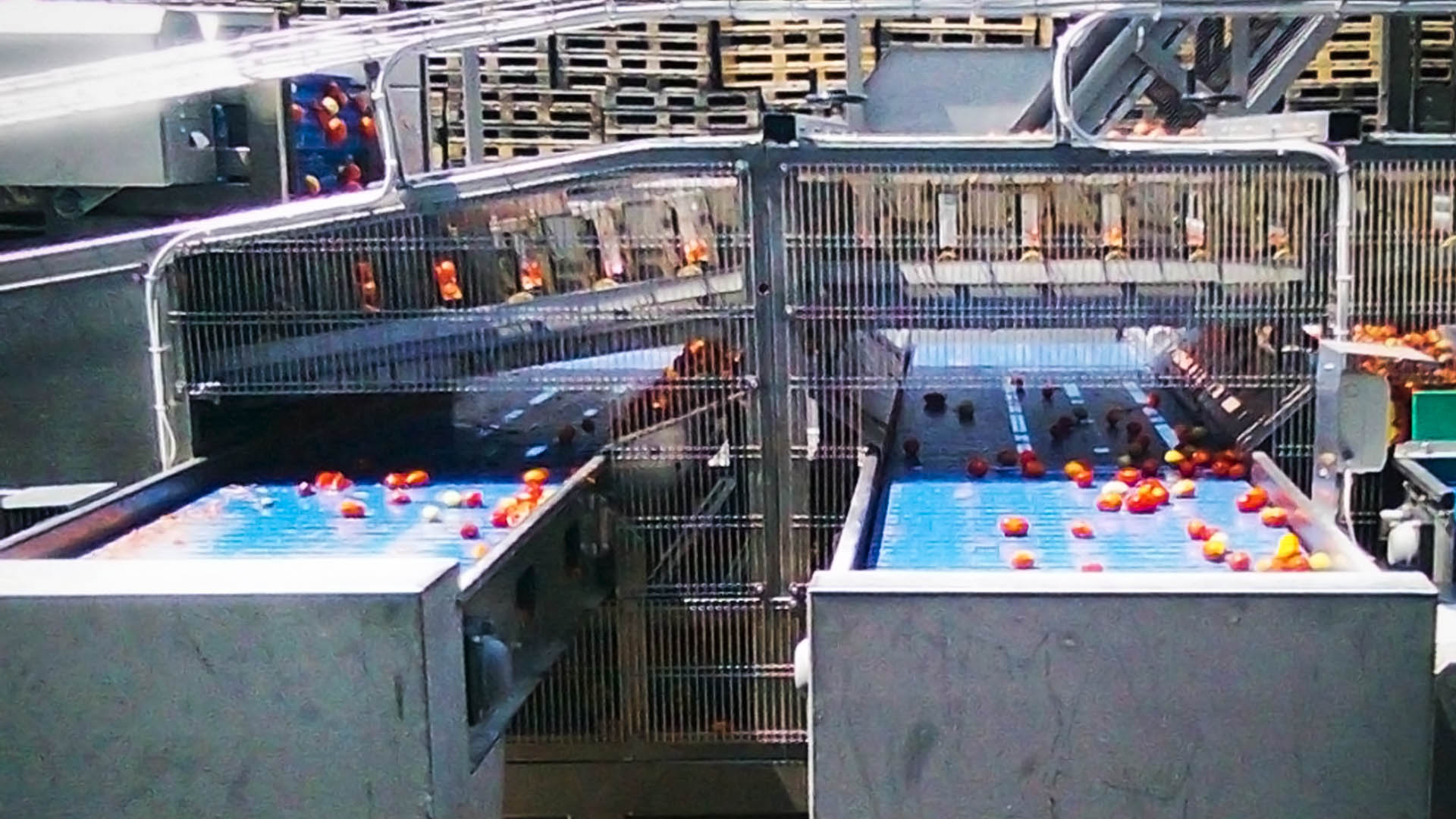

Washing & Sorting Tables

CFT Group provides washing & sorting tables for fruits, tomatoes and vegetables entering into a food processing facility. Configuration types and models are customized according to any requirement and layout.

PRODUCTS: tomato, fruit, vegetables

BENEFITS:

- Reliability and strong construction

- Machinery customization and configuration to fulfill all possible customer requests

- Rolls with different diameter and open space according to application and product

Elevators

We offer different types of elevators designed to lift fruits and vegetables to the desired height. Configuration, type and model can be customized according to the customer requirements and layout. We design and realize robust and reliable elevators in collaboration with the world’s largest manufacturers of plastic belts. We also provide elevators with stainless or roller porters.

PRODUCTS: tomato, fruit, vegetables

BENEFITS:

- HIGH RELIABILITY

- HEAVY DUTY CONSTRUCTION

- POSSIBILITY TO CUSTOMIZE THE MACHINE TO FULFILL DIFFERENT CUSTOMERS’ REQUESTS

The mobile conveyor defoliator-grass remover, featuring a stainless steel structure, is suitable to process fruit and vegetables (especially mechanically harvested tomatoes) containing grass and foliage. It is provided with a continuous conveyor washing system to prevent clogging. The raw material slides on a specifically designed stainless steel conveyor where grass and foliage are separated from the fruit and delivered to a separate exit. The speed is variable in order to adapt the process to different products.

PRODUCTS: tomato, fruit

BENEFITS:

- Very efficient in grass removal

- Reliability and strong construction

- Machinery customization and configuration to fulfill all possible customer requests

- Compact Design

- Easy layout and installation into existing CFT processing line as well as into future expansions

- WORKING CAPACITY: from 20 t/h up to 80 t/h, each unit

Stone Blockers

The system is available in two basic versions for bins and truck unloading, with an input of between 50 and 200 ton/h fresh. We can provide stone blockers also with customized specifications, dimensions and optional fittings. The STONE BLOCKER features two devices with continuous and independent operation which make the machine completely self-cleaning 24/24h. The STONE BLOCKER has redefined the methodologies for raw material reception in areas and countries where tomatoes are mainly harvested mechanically.

PRODUCTS: tomato

BENEFITS:

- Round-the-clock 24h/24h uninterrupted drainage

- Completely self-cleaning machine with continuous devices

- Unloading capacity up to 200 Ton/h in a single Stone Blocker unit

- efficient grid system to prevent stones from coming out together with the tomatoes

- OVER 100 STONE BLOCKER SYSTEMS INSTALLED WORLDWIDE

Buffer Tanks

Buffer tanks are sized according to the production capacity of the plants and they are of great importance to give continuity to the production cycle. The speed of the elevator extracting product from the buffer tank can be automatically adjusted and controlled by the PLC according to the processed product.

PRODUCTS: tomato, fruits, milk, cheese whey, juices, special products (protein broth, etc…)

BENEFITS:

- Reliability and strong construction

- Automation and control function

- Machinery customization and configuration to fulfill all possible requests

- Hygienic design

- Highest quality of the applied material

- Equipped with spray ball and nozzles to guarantee a complete and accurate C.I.P.

- WORKING CAPACITY: from 20 t/h up to 100 t/h each

Size Grader

This fully stainless-steel machine has been designed to size grade tomatoes coming from the unloading lines in order to sort the most suitable products for the various down stream processing lines. The machine can sort up to 3 different sizes by adjusting the distance between the grading rollers (20 to 90 mm) using the supplied wheels. The machine capacity is up to 35/40 Ton/h of fresh incoming tomato.

OVERVIEW

The sizer is a machine installed in the reception area of the fresh product, suitable for the selection of the fruit by diameter.

The operation involves calibrating the product through pairs of tilting rollers, which distance themselves during the transport phase of the product, dropping the fruits on the belts below; from the smaller fruits (called broken fruit) in the first belt to the intermediate fruit (in the second belt) to the largest (suitable fruit) in the last output belt.

The different gauges are adjustable by buttons placed sideways, thus giving to the operator the opportunity to meet all production needs. The rotation of the rollers is managed by a inverter-connected motor, which means that the fruits are distributed in the right drop zone of the sizer. The power can be provided either through a hydraulic duct or dry through an elevator or tape.

In some cases, an underlying channel for recovering the fresh product is installed, so as to eliminate waste even in the event of malfunction.

The supply includes clear documentation and a CE certification for materials in contact with foodstuffs, which is compliant with the current regulations.

PRODUCTS: tomato, fruits

BENEFITS:

- Reliability and heavy-duty construction

- All components made of stainless steel; double drive chain

- The size grader has been designed to minimize maintenance and component replacement (chain, roller pins, etc.)

- WORKING CAPACITY: from 20 t/h up to 40 t/h each unit

Discharge and hydraulic transport

System designed to fulfil relevant needs of the tomato and fruit processing industry. Product can be received in boxes, bins or by gondola. In this latter case the discharge occurs flooding the gondola tub by means of adjustable hoses; in this way the outlet water gently floats the product out.

OVERVIEW

The product is separated from the water by crossing an inclined grill cleaner that lets the product roll into a flume. each progressive flume contains cleaner water and washes while conveying the product to the processing lines. The group is equipped with a redler system to automatically take away stones, mud and foreign bodies.

PRODUCTS: tomato, fruit

BENEFITS:

- High discharge capacity

- The truck can be discharged while a second one gets closer and it is prepared to be discharged keeping the process working

- Continuous discharge of stones, earth and whatever with no needs to stop the line for cleaning operations

- Use of water with multiple levels of clenliness to get a progressive washing of the incoming raw product

- Water saving by means of a water filtration system maintaining a high quality of finished product