Processed Cheese Systems

Thanks to our consolidated expertise and know-how we provide high-technology turn-key plants as well as single machines specifically engineered for the Processed Cheese sector.

In this section you will be able to discover our wide range of equipment specifically dedicated to the Processed Cheese industry, such as complete plants for the production of soft/fresh, semi-hard and hard cheeses and pasta filata cheese like mozzarella or caciocavallo.

Our detailed know-how starts from milk receiving, passing through sterilization and separation phases up to standardization, stretching, maturation, curd making, draining, molding, pressing, brining, filtration, CIP (cleaning-in-place), heat treatment and automation.

Cradle cheese-vat contributed to make the brand Milk Project famous among all the machines on the Italian and international market, it is certainly the cheese cradle that represents one of the highly performing excellences for the production of fresh delicate cheese both soft and crust ones. The machine was designed for the production of weak delicate curd with a high humidity level. Milk Project has successfully made more than 250 cheese cradles for factories leader in the production of fresh mediterranean cheese.

PRODUCTS: soft fresh cheese, fresh cheeses with crust, marbled cheese, white paste and semi-hard cheese

BENEFITS:

- HIGHLY PERFORMING IN THE PRODUCTION OF CURD WITH HIGH HUMIDITY LEVEL

- CONTINUOUS LOAD AND UNLOADING IN SEQUENCE OF CHEESE VATS DURING ALL THE DAILY PRODUCTION

- EASILY WASHED AND SANITIZED

- MINIMUM MAINTENANCE AND FAST ACCESS FOR THE OPERATOR

CIRCULAR VAT

Milk Project produces MINI CIRCULAR VATS that represent a strong point in processing curds for fine cut to produce long, medium maturing cheese.

OVERVIEW

One of the main features of the Circular Vat is the double side with indirect steaming or with hot water which enables the curd bake during the technological processing in boiler.

Further benefits of the Circular Vats are the cutting, stirring tools, the double drain in the main bottom dividing the outflow collector of the curd from the outflow collector of the CIP washing.

Milk Project Vats are made to guarantee the highest quality of the product and the greatest easiness in handling sanitization and maintenance.

PRODUCTS: curds to produce hard, semi-hard cheese and string cheese.

BENEFITS:

- HIGH RETURN, VERY GOOD QUALITY IN PRODUCING CURDS FOR FINE CUT

- CONTINUOUS SEQUENTIAL LOADING AND UNLOADING OF VATS FOR THE WHOLE DAILY PRODUCTION

- MODULAR BODY THAT MAKES THE IMPLEMENTATION OF PRODUCING UNITS POSSIBLE IN THE FUTURE

A pumping device particularly kindred for transferring breakable products such as delicate curds for Fresh Cheese. THE COMPRESSED AIR PUMP is a very flexible machine that provides the best option for food industry to transfer thin, viscous, clotty fluids tender to cutting.

OVERVIEW

The compressed air pump device, with adjustable pressure, is a project technologically advanced which distinguishes THE AIR PUMP from other mechanic rotary lobe or helical rotor pumps, since it keeps unchanged the primary properties of the product, during the pumping process.

PRODUCTS: soft fresh cheese, fresh cheeses with crust, marbled cheese, white paste and semi-hard cheese, mostly for all food fluids: thin, viscous, clotty fluids tender to cutting

BENEFITS:

- THE COMPRESSED AIR PUMP GUARANTEES THE PRODUCT BY ITS SMOOTH PUSH TO KEEP ALL THE PRIMARY PHYSICAL CHEMICAL PROPERTIES DURING THE PUMPING STAGE

- REGULATES EASILY THE RANGE OF PUMPING OF THE FLUID PROCESSED

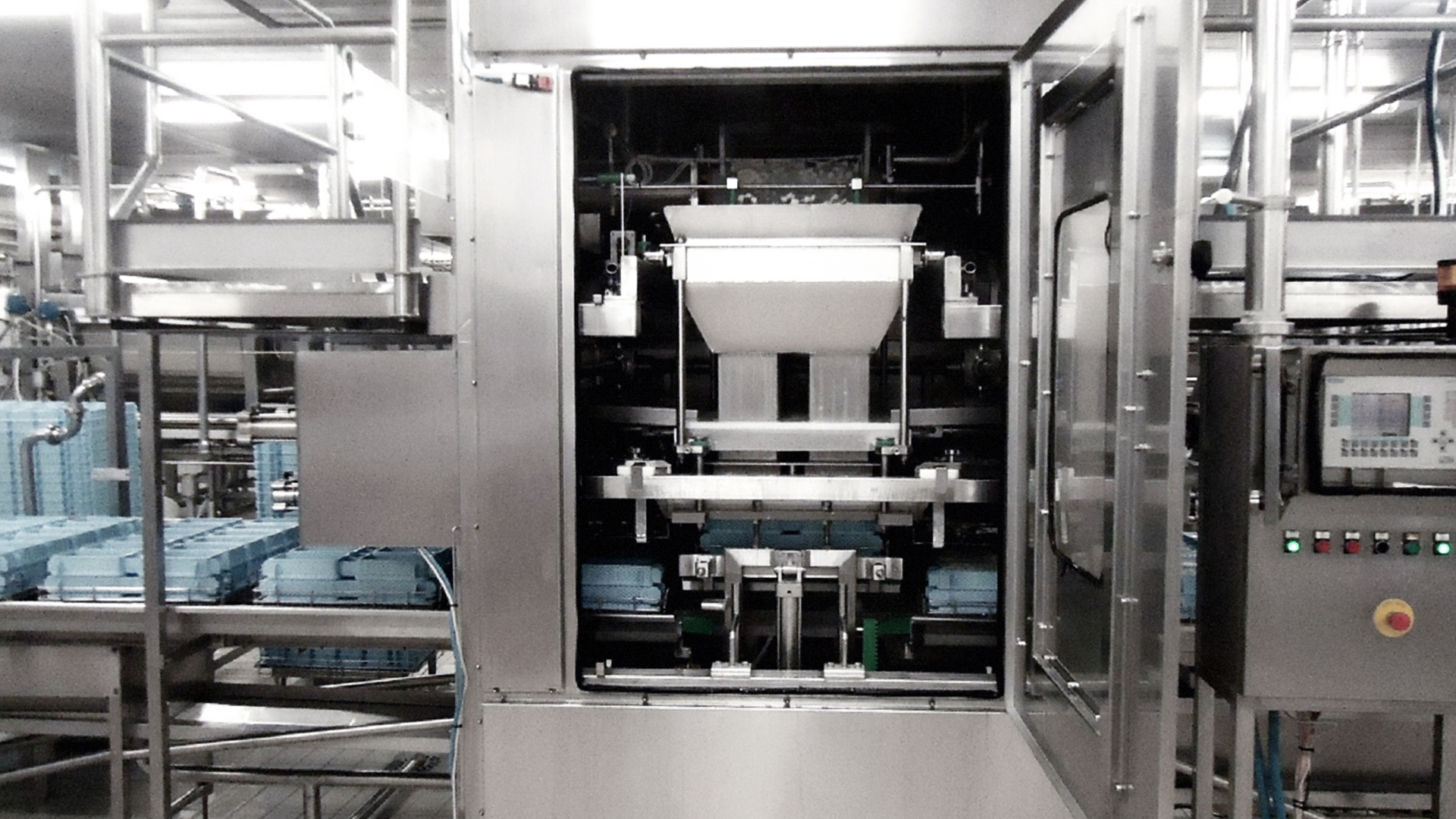

The Volumetric dosing machineries MP-F and MP-R are designed by Milk Project for the volumetric dosing of curds to mold Fresh, hard and semi-hard cheese.

OVERVIEW

Designed for dairy factories that produce cheese with set up weight to meet the market requests. These ones guarantee a high manufacturing capacity and a reference point for quality design.

The efficiency and accuracy of the dosing system of Milk Project dosing machineries, enable to assure and achieve the performances agreed with the customer.

Milk Project dosing machineries are designed to fulfill different technological quality requirements of the product being processed.

PRODUCTS: soft fresh cheese, fresh cheeses with crust, marbled cheese, white paste and semi-hard cheese, curd blocks for string cheese

BENEFITS:

- GuARANTEES A HIGH MANUFACTUIRNG CAPACITY IN THE DOSAGE OF A BROAD RANGE OF CHEESE IN VARIOUS SHAPES AND WITH DIFFERENT TECHNOLOGY

- ACCURACY IN CALCULATING CURD QUANTITY TO ENTER THE MOLD BLOCK

- SETTING OF DOSING PARAMETERS IS EASILY REACHABLE

- FAST CHANGE OF SHAPE THROUGH A MONOBLOCK HEAD

- EFFICIENT WASHING SANIFICATION SYSTEM

- FAST MAINTENANCE REDUCED TO MINIMUM

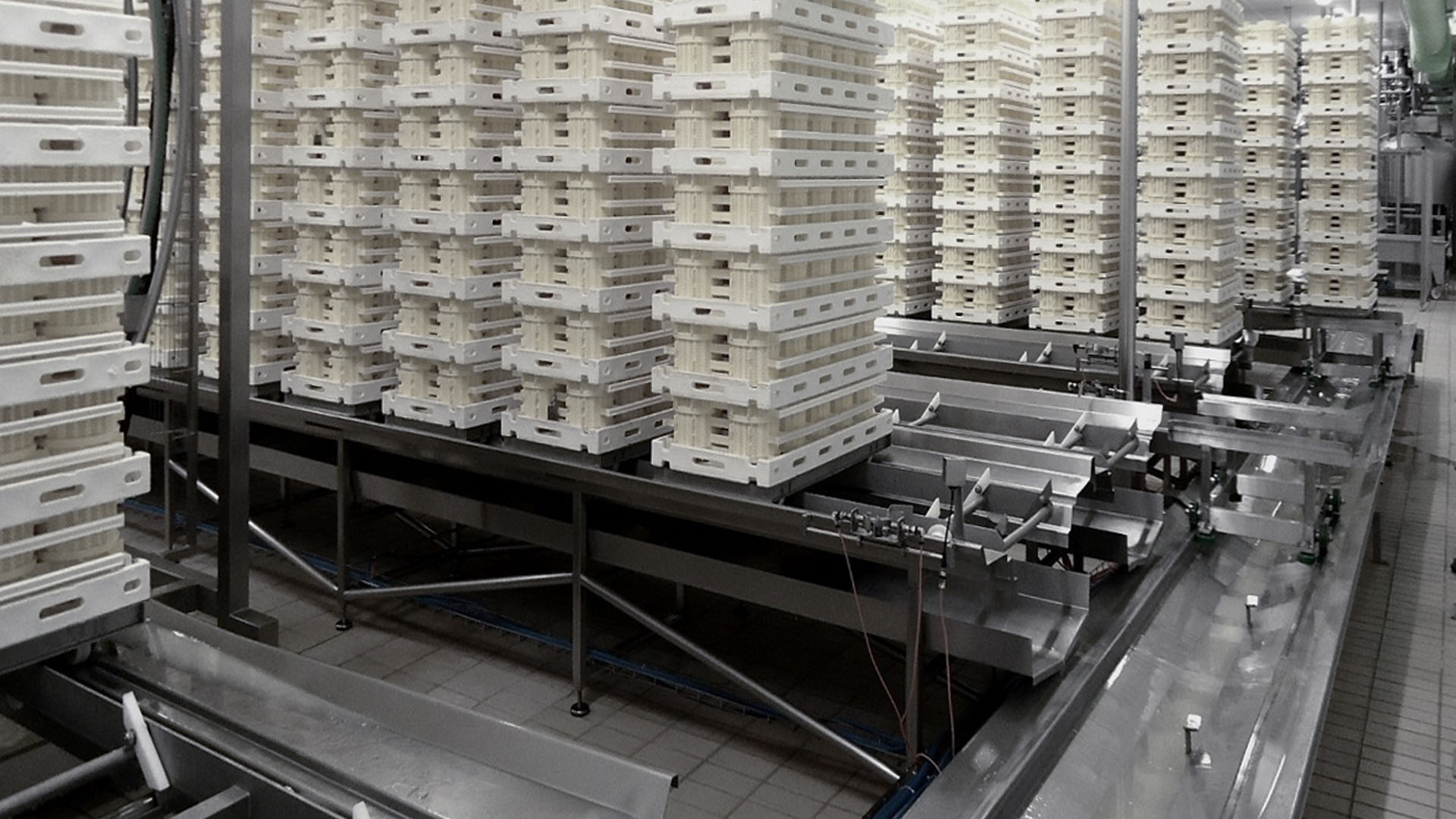

The mechanized tracks coordinate moving cycles of single mold blocks or stacked ones upon timing of the pre-selected technological recipe. The mechanized tracks together with stacking, unstacking, overturning assemblies complete the automation that has to handle processing stages of molding and the heat-treatment in hot chamber of the cheese being processed. Projects are worked out and customized upon the customer’s specific requirements.

PRODUCTS: soft fresh cheeses, fresh cheese with crust, marbled cheeses, white paste and semi-hard cheeses, semi-finished for string cheeses

BENEFITS:

- THE MECHANIZED TRACKS TOGETHER WITH STACKING, UNSTACKING ASSEMBLIES AND OVERTURNING SINGLE MOLD BLOCKS AND/OR STACKED ONES ALLOW TO INCREASE THE AUTOMATION TARGET IN FACTORIES WHICH PRODUCE HIGH QUALITY CHEESE

STACKERS / UNSTACKERS FOR MOLD BLOCKS

Machines for stacking and for unstacking to exploit the utmost height of the rooms and considerably reduce the surface of the area where the automatic belt will be installed to produce cheese. Mold blocks with product can be stacked on wheeled carts or without carts according to the type of scrolling tracks designed by the project. The mold blocks with product can be stacked on trolleys with wheels or without trolley depending on the type of tracks designated by the project .

PRODUCTS: soft fresh cheese, fresh cheeses with crust, marbled cheese, white paste and semi-hard cheese, semi-finished for string cheese

BENEFITS:

- STACKING AND UNSTACKING ASSEMBLIES CARRY OUT IMPORTANT CYCLING AUTOMATIC WORK SUCH AS SUPPLYING DOSING MACHINES WITH SINGLE MOLD BLOCKS OR MACHINES FOR OVERTURNING, STEAMING IN HOT CHAMBER AND CURING PLANTS WITH STACKED BLOCKS

- THE MACHINES ARE PROTECTED BY PERIPHERAL PANELS AND ELECTRONIC DEVICES ASSURING VERY GOOD SAFETYTO THE LINE WORKPLACE

- MAXIMUM FLEXIBILITY OF THE MANAGEMENT PROGRAMS OF PRODUCTION ACTIVITIES.

- EASY PROCEDURE FOR WASHING SANIFICATION DEVICE

- FAST MAINTENANCE REDUCED TO minimum

CHEESE OVERTURN SYSTEM

Milk Project makes three types of overturning models: 1) Turners for single mold blocks for hot automatic chambers; 2)Turners for stacked mold blocks for hot automatic chambers; 3)Turners for stacked mold blocks for hot chambers manually handled and for maturation cells

PRODUCTS: soft fresh cheese, fresh cheeses with crust, marbled cheese, white paste and semi-hard cheese, curd blocks for string cheese

BENEFITS:

- OVERTURNING ASSEMBLIES CARRY OUT AN IMPORTANT WORK, TO BALANCE MOISTURE OF THE PRODUCT BEING PROCESSED DURING THE BAKING STAGE IN HOT CHAMBER AND MATURATION IN CELL

- MACHINES ARE PROTECTED BY peripheral PANELS AND BY ELETCTRONIC DEVICES GRANTING A VERY GOOD SAFETY TO THE WORKPLACE AND THE LINE

- MAXIMUM flexibility

- MAINTENANCE IS FAST CARRIED OUT AND REDUCED TO MINIMUM

These systems reduce stopover for maturation and drain the whey of cheese being processed. Mechanized tunnels for hot chambers permit to maximize the heat capacity of the product stacked and farther increase the baking temperature in the inner chamber of the tunnel, with isothermal sides by injecting food steam.

PRODUCTS: soft fresh cheese, fresh cheeses with crust, blue cheese, white paste and semi-hard cheese, curd blocks for string cheese

BENEFITS:

- Besides reducing maturing time, mechanized tunnels allow an appreciable energy saving since there is no heat loss during the production cycle

- Mechanized tunnels grant the utmost flexibility in handling processing cycles

- Equipped with efficient washing sanitation device

- Maintenance is fast carried out and reduced to the minimum

- Projects are customized according to specific customers’ requests

Plants for salting cheese successfully by deep immersion. The product of mold blocks stacked is soaked in salting vats, in stainless steel AISI 316 L, for a fixed time. The regular brine concentration is assured by a fluid dynamic action inside the vat. Brine is cooled passing through a tubular cooler, supplied with icy water.

PRODUCTS: soft fresh cheese, white paste cheese, semi-hard cheese, hard cheese

BENEFITS:

- MILK PROJECT SALTING SYSTEMS BY SOAKING GUARANTEE HIGHEST HYGIENE, BRINE QUALITY AND CHEESE PROCESSED

- FLOW MANAGEMENT IS DONE BY MEANS OF PROCESSING SANITARY VALVES

- LOADING AND UNLOADING SERVICE OF STACKS IS CARRIED OUT BY HOISITNG PLANTS OR A SELF-CONTROLLED BRIDGE CRANE

- SALTING PROCESS OF CHEESE IS CONTROLLED BY A SW, A PLC AND TOUCH SCREEN PANEL WHERE THE OPERATOR CAN SET PROCESSING