Peelers

Our peelers can process a great variety of products thanks to the application of a specific technology depending on the type of product being treated.

Our peelers’ range features an innovative high vacuum technology and, thanks to the no-contact between product and water, this equipment is able to provide high ecological value because of the non-polluting liquid discharge. These machines can be featured with different technologies such as abrasive or steam peeling ones. The choice of the machine is directly related to the type of vegetables customers intend to process.

The Geyser Steam peeler machine has been engineered for carrots and potatoes peeling and is able to prepare different kind of final products.

PRODUCTS: carrots, potatoes

BENEFITS:

- special vessel design for optimal product mixing and perfect treatment

- complete stainless-steel structure including pressure vessel

- complete range of capacity from 2 up to 25 tons/h

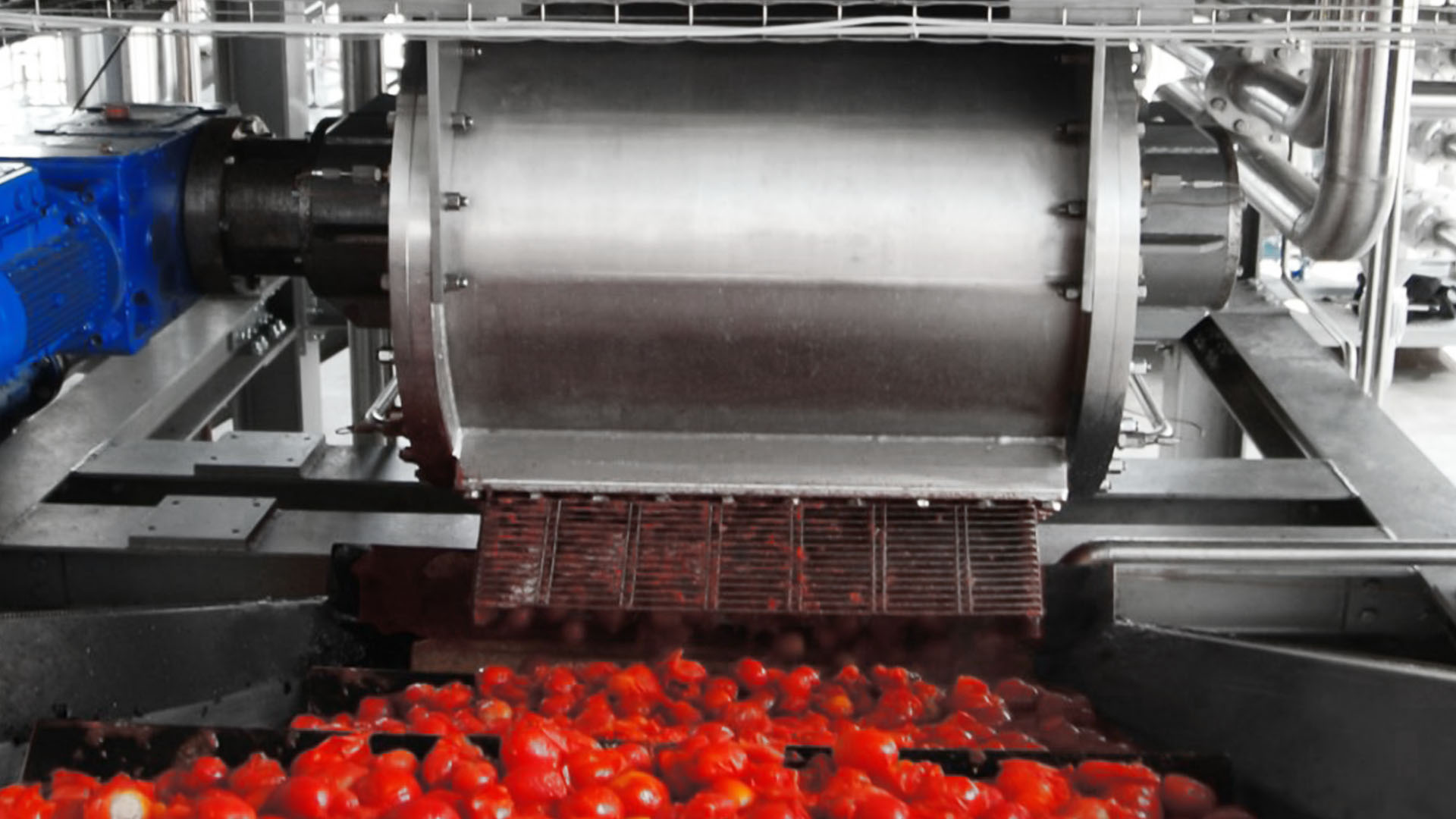

CFT Group’s Vesuvio Millenium peeler provides a very high-quality final product and is able to successfully deal with very difficult-to-peel tomatoes. Its flexibility enables to process up to 90 -100 t/h of fresh tomato and its overall design enables to treat the product very gently.

OVERVIEW

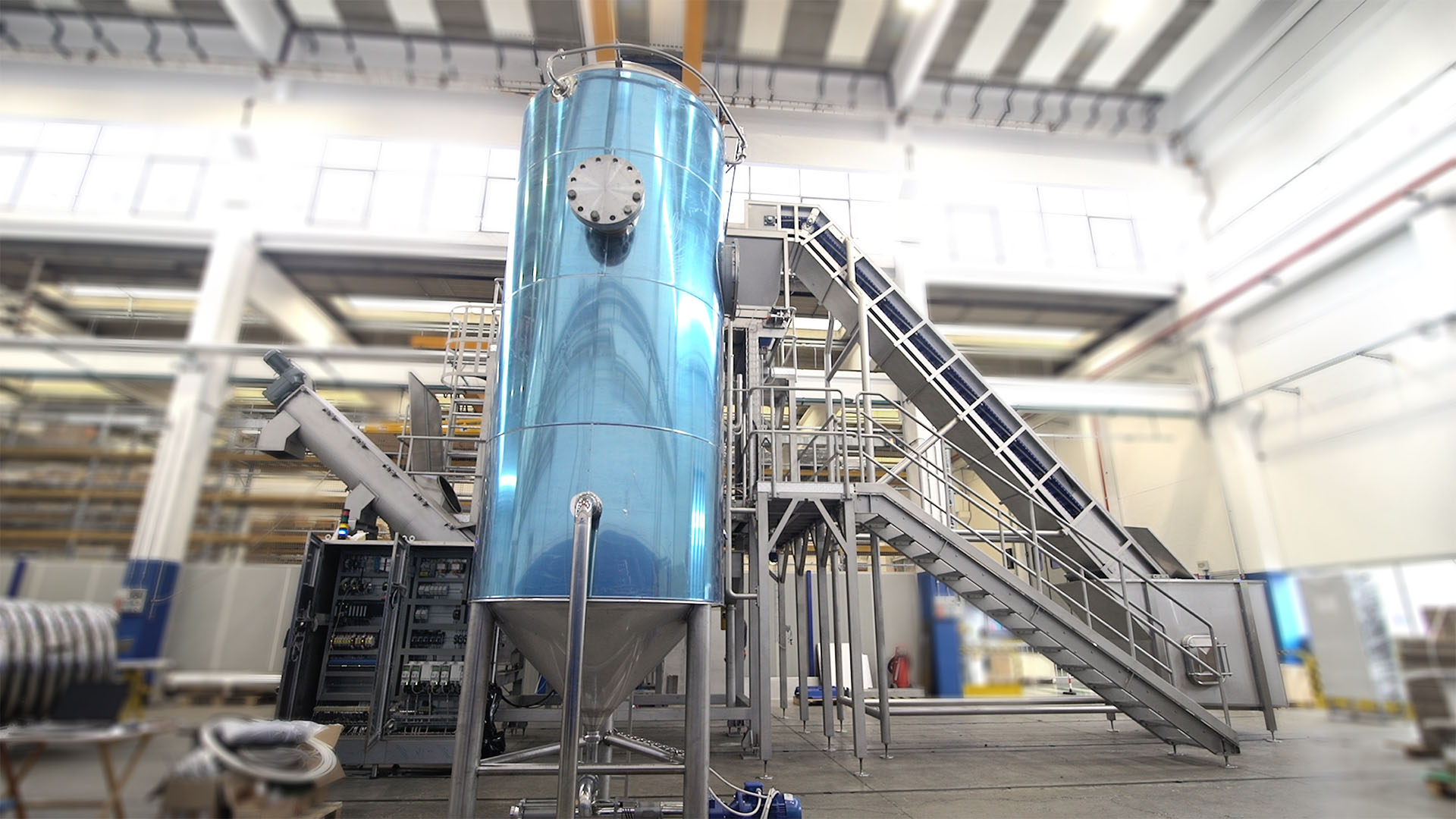

The peeling temperature is quite low (no more than 106 – 108 °C) if compared with older traditional techniques, allowing to preserve most of the tomatoes’ original texture and limiting energy consumption. The peeling machine VESUVIO MILLENIUM consists of the following components:

- Flight elevator for product feeding – it is moved by an inverter power ventilated gear motor. It can be fed by a hydraulic channel or a conveyor belt for dry product transfer;

- Rotary valve for product infeed – it is moved by an inverter power ventilated gear motor and it is designed to meter product to the peeling body. The function of this valve is to keep the pressure constant inside the scalding area.

- Peeling body consisting of one pressurised chamber hosting a rotor split into sectors. The rotor is moved by an inverter gear motor. Direct steam or a combined mix (superheated water and direct steam) is used for the scalding cycle.

PRODUCTS: tomatoes

BENEFITS:

- LOW STEAM CONSUMPTION

- LOW MAINTENANCE COSTS

- EFFORTLESS PROCESS MANAGEMENT AND CONTROL

The machine is fully automatic and its operation is user-friendly. The presence of an operator is only required on a limited number of occasions.

OVERVIEW

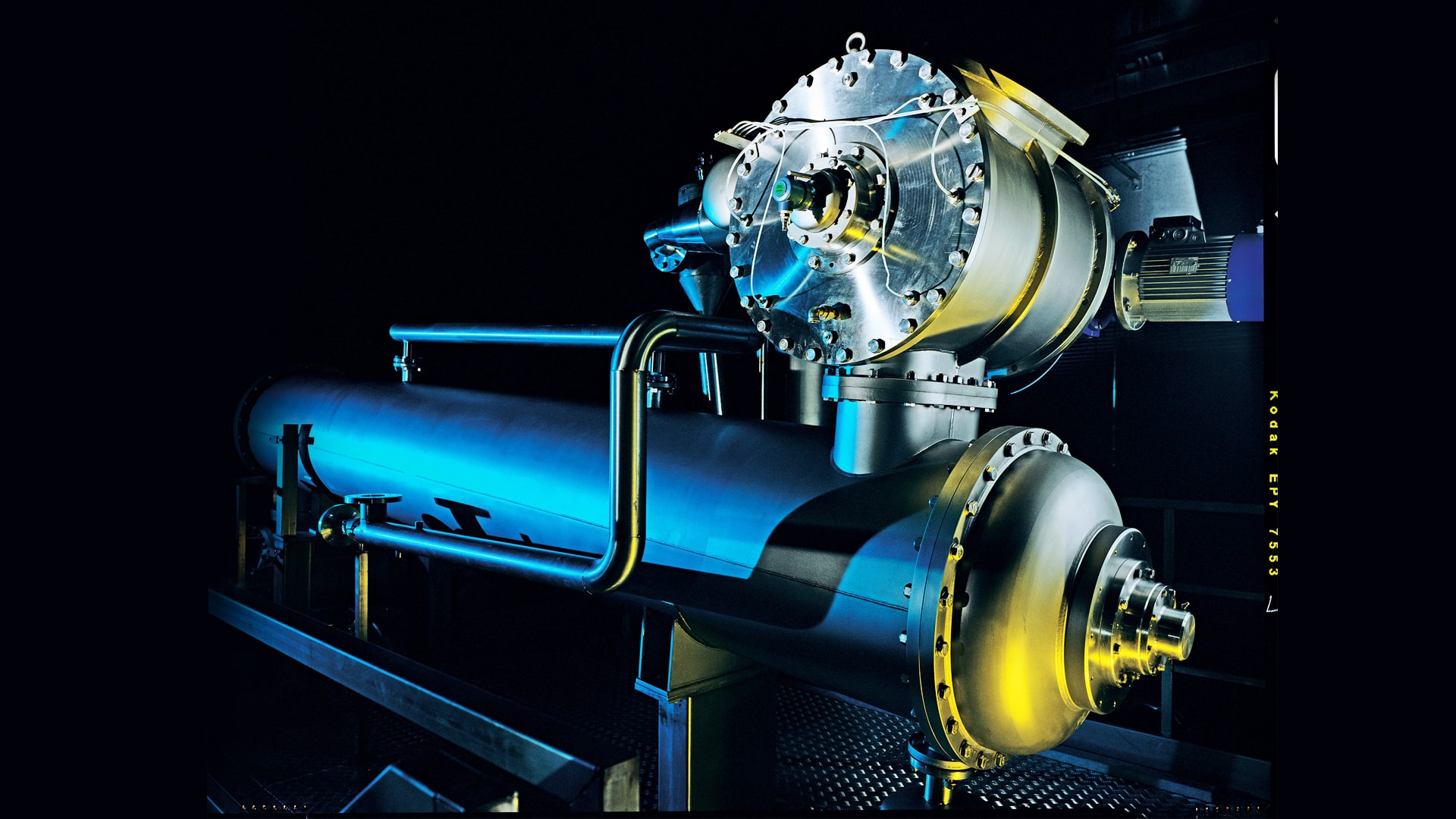

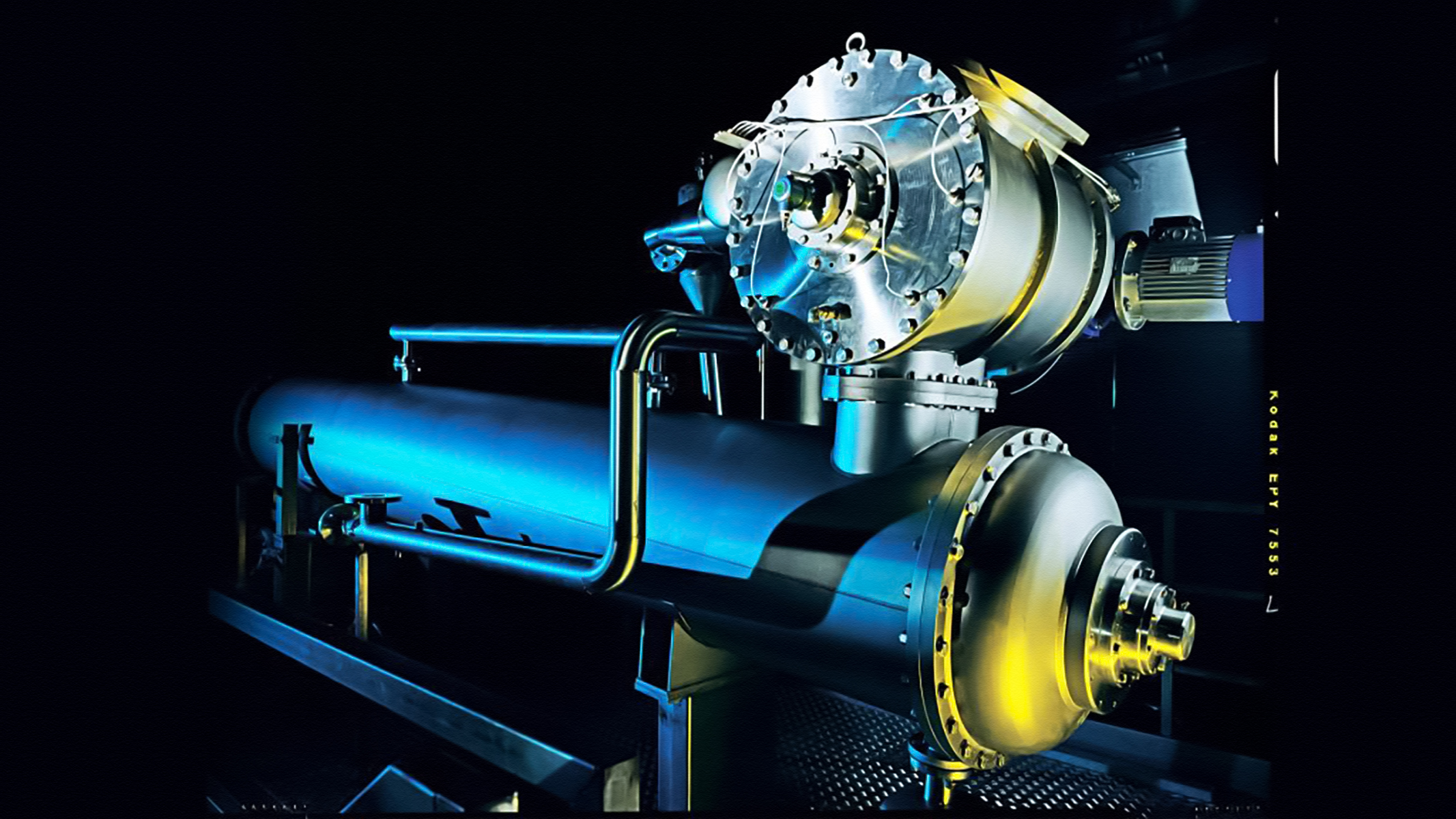

The peeling machine TSP consists of the following components:

- Flight elevator for product feeding

- Rotary valve for product infeed

- Peeling body consisting of a shell and tube featuring an internal feedscrew for product advancement.

- Intermediate rotary valve

- Vacuum body – the evaporation process detaches the skin and prepares the fruit for the next processing step in the skin separators;

- Rotary valve for product unloading

- Frame, made of stainless steel or galvanized steel, as required by the customer;

- Skin unloading conveyor with knurled rollers

- Mono pump with hopper – it is used to recover juice at the outlet of the unloading rotary valve;

- Automatic washing system

- Electric control panel for machine operation using either a touch-screen monitor located on the panel or the PC fitted in the control room

PRODUCTS: tomatoes, carrots, potatoes

BENEFITS:

- Great flexibility and process control

- High peeling efficiency due to a low product level inside the heating vessel and to the parallel steam flow which provides uniform heating