Kegs Handling

Complete End-of-Line range dedicated to kegs handling: kegs centering devices, palletizers and depalletizers, pallets stackers and unstackers, pallets’ warehousing solutions and control stations.

Thanks to the know-how of our company Comac, we can design a wide range of end of line equipment for kegs, consisting of two separate stations for palletizing and depalletizing, single or double robot devices, or combined devices equipped with a single gripper that allows both operations to be performed. All the operations carried out by the machines are monitored by sensors to verify the correct execution of the work cycles.

PALLET/KEG CENTERING DEVICES

The pallet/keg centering systems are designed to correct the pallet position on the conveyors and center the empty kegs located on the pallet in order to allow the depalletization robot to perform its manoeuvers.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: cans, glass bottles, kegs

BENEFITS:

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

KEG LINE DRY AREAS

In small and medium capacity lines, which do not necessarily require automatic depalletization operations, the dry area can consist of a palletization robot that also performs operations such as keg fitting disinfection, capping and collar application.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: kegs

BENEFITS:

- Flexible solutions, according to the line configuration and output

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

- Speed range: from 60 KPH to over 1.200 KPH

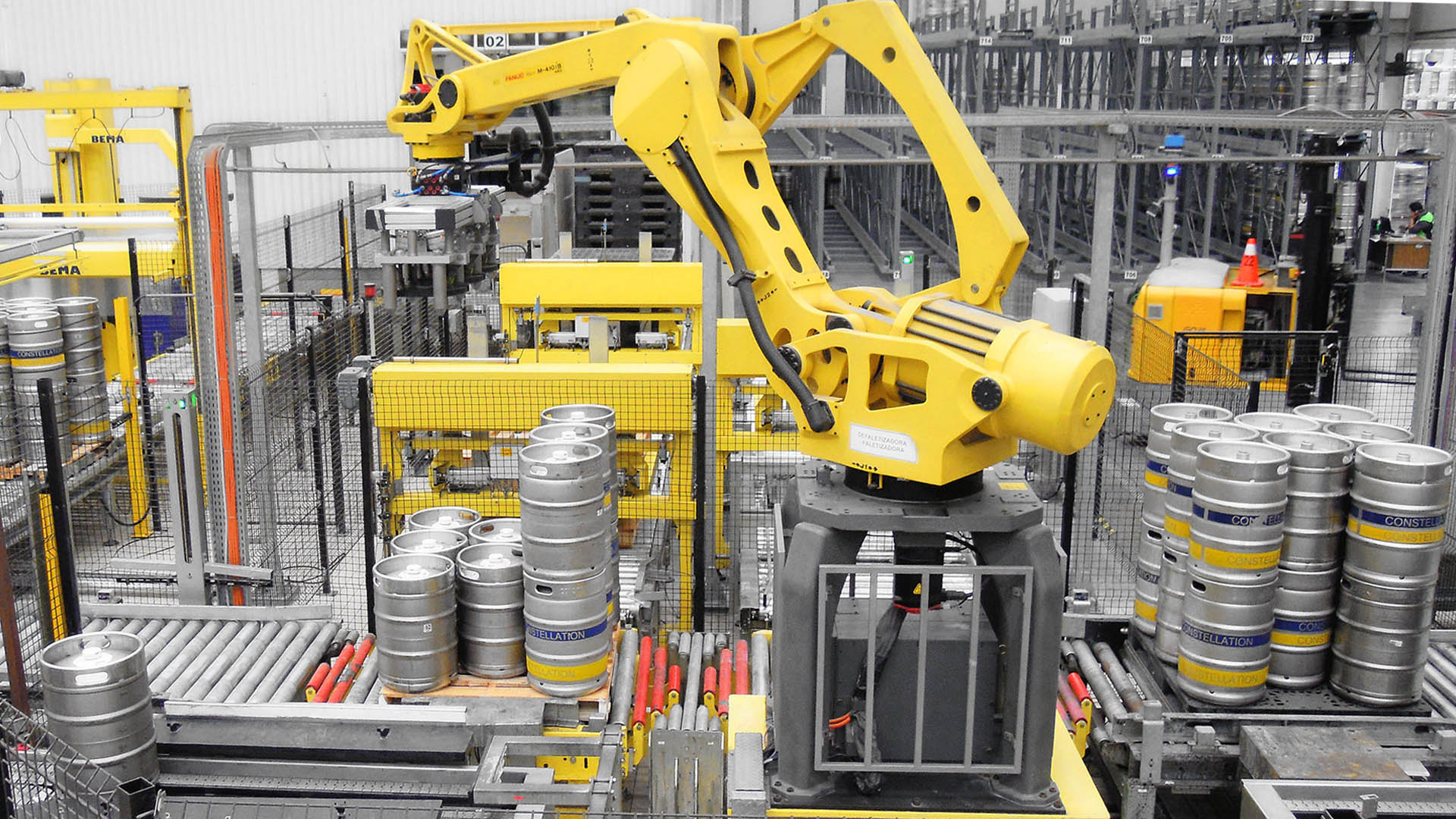

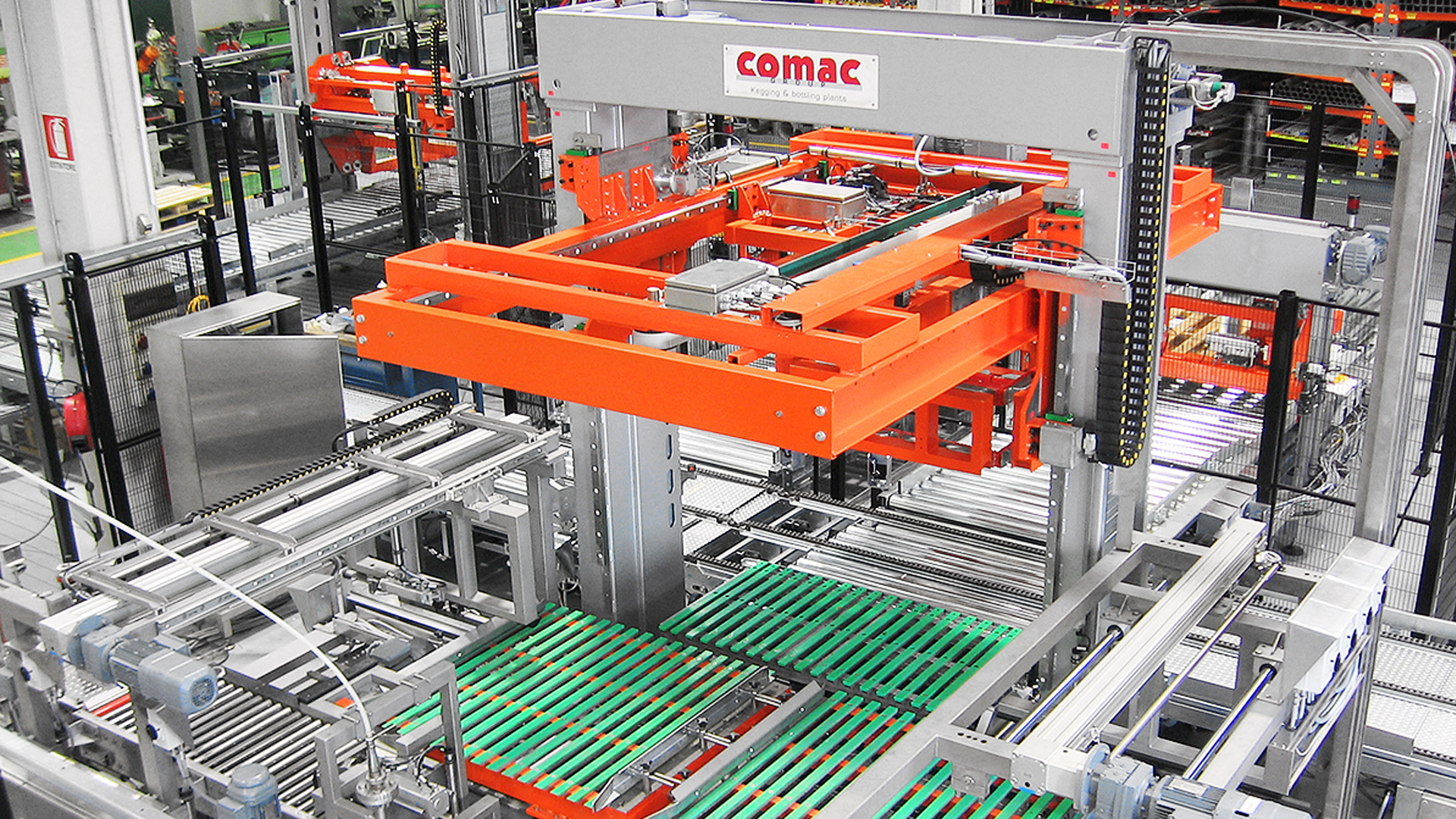

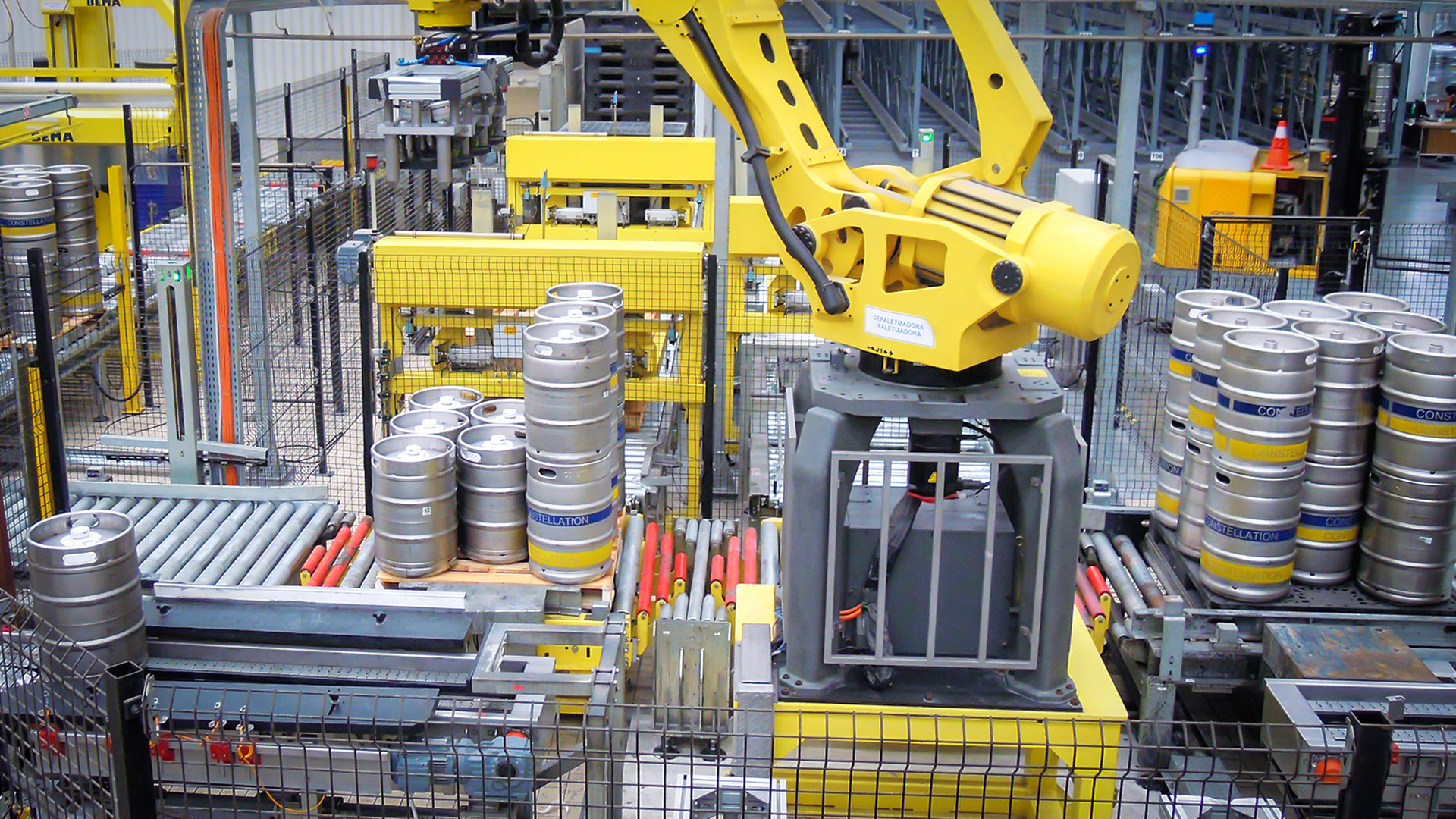

KEG DEPALLETIZERS AND PALLETIZERS

Premium robots, sized according to the keg pallet layouts to be managed, complete with keg-seizing heads suitable for dealing with one or more kegs at a time, according to the keg configuration on pallets and keg line speed.

Portal type depalletizers and palletizers, or combined machines, suitable for depalletizing and palletizing a whole layer of kegs at the same time.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: kegs

BENEFITS:

- Flexible solutions, according to the line configuration and output

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

- Speed range: from 60 kph to over 1,200 kph

PALLET DESTACKERS AND STACKERS

Comac destackers are designed to unpile pallets loaded with empty kegs returning from the market, in order for the depalletization system to receive a single layer of kegs. Stackers, on the contrary, pile the required number of pallets loaded with full kegs, that can then be unloaded from the pallet conveyors by a fork lift truck.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: cans, glass bottles, kegs

BENEFITS:

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

PALLET CONTROL STATIONS

Pallet inspectors detect broken or defective pallets, by means of feelers, and reject them towards an unloading station or a broken pallet magazine.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: cans, glass bottles, kegs

BENEFITS:

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

- Speed range: from 60 kph to over 1,200 kph

PALLET WAREHOUSING SOLUTIONS

Pallet warehousing solutions can pile and store empty pallets when they are not required by the palletization system, unpile and supply empty pallets to the palletization system when it requires them; they can also pile and store broken pallets detected by a pallet inspector, or empty pallets that, for whichever reason, will not be used by the palletization system. Integrated in a keg line dry area, they help manage the pallet flow, avoiding down-times.

PRODUCTS: beer, cider, sparkling and still wine, carbonated soft drinks

FORMATS: cans, glass bottles, kegs

BENEFITS:

- Flexible solutions, according to the line configuration and output

- High reliability and efficiency rates

- Equipped with components of well-known brands, easy to find on local markets

- After sales technical assistance available 24 hours, 6 days a week

- Speed range: from 60 kph to over 1,200 kph