Level fillers for carbonated products

Our fillers’ portfolio for Beverage industry includes a wide selection of filling machines featuring isobaric level technology which have been specifically engineered to fill carbonated drinks.

This machines’ range is based on counter-pressure filling technology, suitable to fill carbonated drinks in cans or PET bottles.

These machines feature “state of the art” technology and can be inserted in medium or high-capacity lines. This equipment is the result of an advanced research and development commitment oriented towards high quality standards.

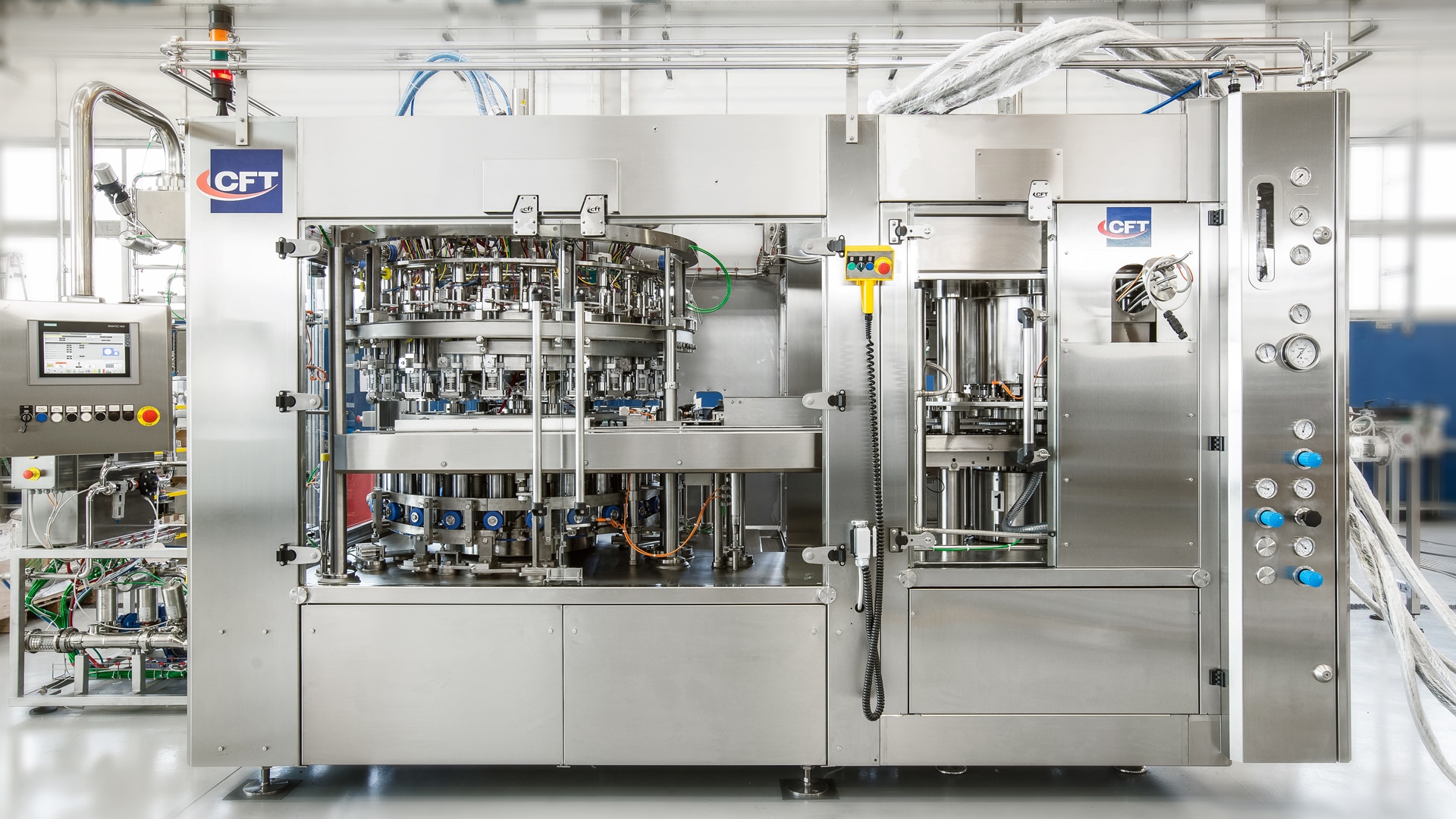

PEGASUS - CAN FILLING MONOBLOCK

PEGASUS can filling / seaming monoblock is based on counter-pressure filling technology, suitable for filling carbonated and still beverages in aluminium cans. The machine is designed to rinse cans with CO2 or other inert gas, fill them with product and finally seam the lids. The use of electro-pneumatic filling valves and seamer manufactured by sector leading companies makes of this machine a perfect solution for the low/medium capacity lines (from 3,000 up to 6,000 cph).

Products: beer, carbonated and still water, carbonated and still soft drinks, sparkling and still wine, ready to drink.

Formats: two-pieces aluminium cans, Lids from size 200 to 206, volume from 200 ml to 1.000 ml.

Benefits:

- Optimal settings for all filling parameters (flushing, evacuating, pressurization, filling, snifting…).

- Dedicated recipes for different types of product adjustable and that can be selected by HMI.

- All filling parameters remain unchanged; always stay the same; they do not depend on the capacity of the machine, as for classical mechanical fillers.

SAGITTA - bottle filling monoblock

SAGITTA glass bottle rinsing / filling / capping monoblock is based on counter-pressure filling technology, suitable for filling carbonated and still beverages in glass bottles. The machine is designed to rinse the bottles with water or other disinfectant solutions, fill them with product and finally close them. The use of electro-pneumatic filling valves makes this machine a perfect solution for the low/medium capacity lines (2.500 up to 6.000 BPH.)

Products: beer, carbonated and still water, carbonated and still soft drinks, sparkling and still wine, ready to drink

Formats: glass bottles with crown cork, twist off cap, aluminium screw ROPP cap, glass bottles with natural mushroom cork and wirehood, aluminium bottles with crown cap, twist off cap, aluminium screw ROPP cap, volume from 200 ml to 1.000 ml.

Benefits:

- Optimal settings for all filling parameters (flushing, evacuating, pressurization, filling, snifting…)

- Dedicated recipes for different types of product, adjustable and that can be selected by HMI

- All filling parameters remain unchanged; they do not depend on the capacity of the machine, as for classical mechanical fillers

One of the top sellers compact solutions for the micro-brewing market: Microbrew is our compact filler & seamer monoblock especially engineered to provide premium equipment to small & medium sized breweries to help them reaching high performance.

Products: beer

Formats: cans

Benefits:

- HIGHLY PERFORMING: up to 6.000 cph

- GUARANTEED QUALITY: lowest oxygen pick-up in the market

- HIGHEST LEVEL OF SEAMING QUALITY

Master G Tech

MASTER G Tech is a filler for glass bottles. It is based on counter-pressure filling technology, suitable to fill carbonated and still drinks. This machine is the result of advanced research and development towards a target of heavy/duty construction and high-quality standards (having always been our top goal) in the field of carbonated and still products (water, soft drinks, beer, juices).

Products: beer, carbonated soft drinks

Formats: glass bottles

Benefits:

- HYgienic design: self-draining base, adjustable water nozzles

- Excellent product quality

- Fully automatic dummy bottles insertion

- Electronic control of the filling phases

MASTER RS GLASS/PET model is based on counter-pressure filling technology, suitable to fill carbonated and still beverages in glass and PET bottles. This machine is the result of an advanced research and development towards very high quality standards. With this machine CFT Group is offering one of its best technologies for the medium/high capacity lines (from 5,000 up to 60,000 bph).

Products: carbonated and still water, carbonated and still soft drinks, beer, juices (fruit and vegetable) hot filled (80-90°C) or cold filled, sparkling and still wine. ready to drink and liquors.

Formats: glass bottles, PET bottles.

Benefits:

- Excellent performance in terms of filling precision, product handling and oxygen content control, with phases controlled by plc

- centralized decompression recovery system

- Hygienic design coupled with heavy duty construction

- speed range from 3.000 to 90.000 bph

MASTER PET RS/SC is based on counter-pressure filling technology, suitable to fill carbonated and still drinks in PET bottles. With this machine the Group is offering “state of the art” technology for the medium/high capacity lines (from 5,000 up to 70,000 bph).

Products: still drinks, carbonated soft drinks

Formats: PET bottles

Benefits:

- speed from 5.000 up to 70.000 bph with flowmeter technology or electropneumatic control

- Possibility to fill still product in gravity conditions (NO pressure-NO extra CO2 waste)

- separate air return system which allows to avoid any possible product contamination