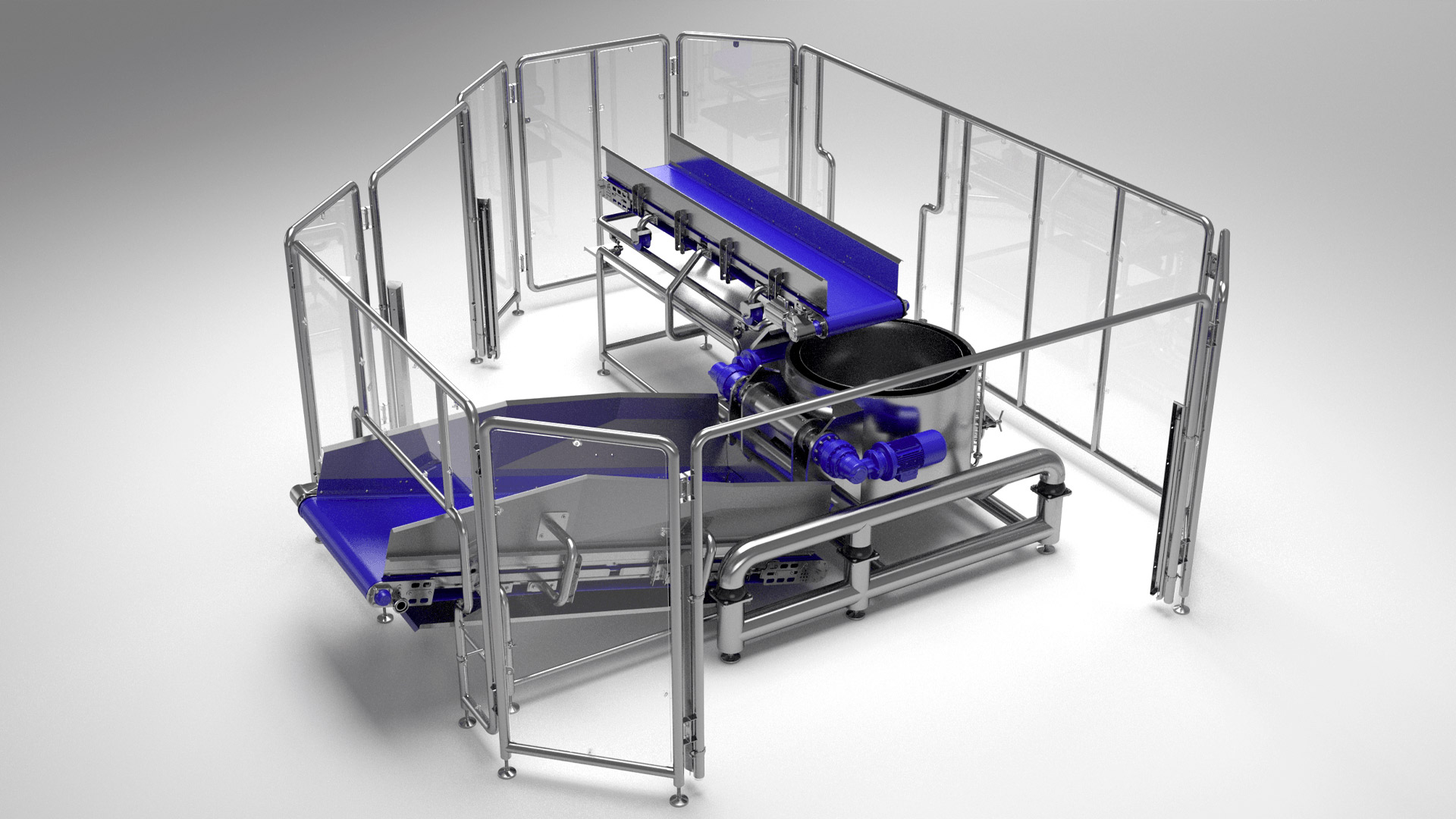

Our Product Treatment technologies provide complete solutions for fresh and pre-cooked vegetables processing and thermal treatment both for packaged and loose products.

The production range is divided in two main categories: vegetable solutions and thermal treatment.

VEGETABLE SOLUTIONS

- 4th range: complete solutions for Fresh-cut and mixed salad preparation (lettuce, lettuce, romaine, escarole, baby-leaf, radicchio, etc.) and potatoes, carrots, and beetroots both fresh and ready to eat.

- 3rd Range: complete lines for frozen fruits and vegetables (IQF fruits and vegetables).

- 5th Range: complete solutions for spinach and cooked vegetables.

- Chips and French Fries: complete lines to produce chips and French fries

- Legumes/Pulses: complete lines for rehydration, cooking, filling, packaging and sterilization for legumes (beans, peas, fava beans, chickpeas etc.) in cans, jars and pouches.

- Pickles: complete lines for cooking, filling, packaging and pasteurization for pickles (cucumber, peppers, courgettes, carrots etc.) in cans and jars

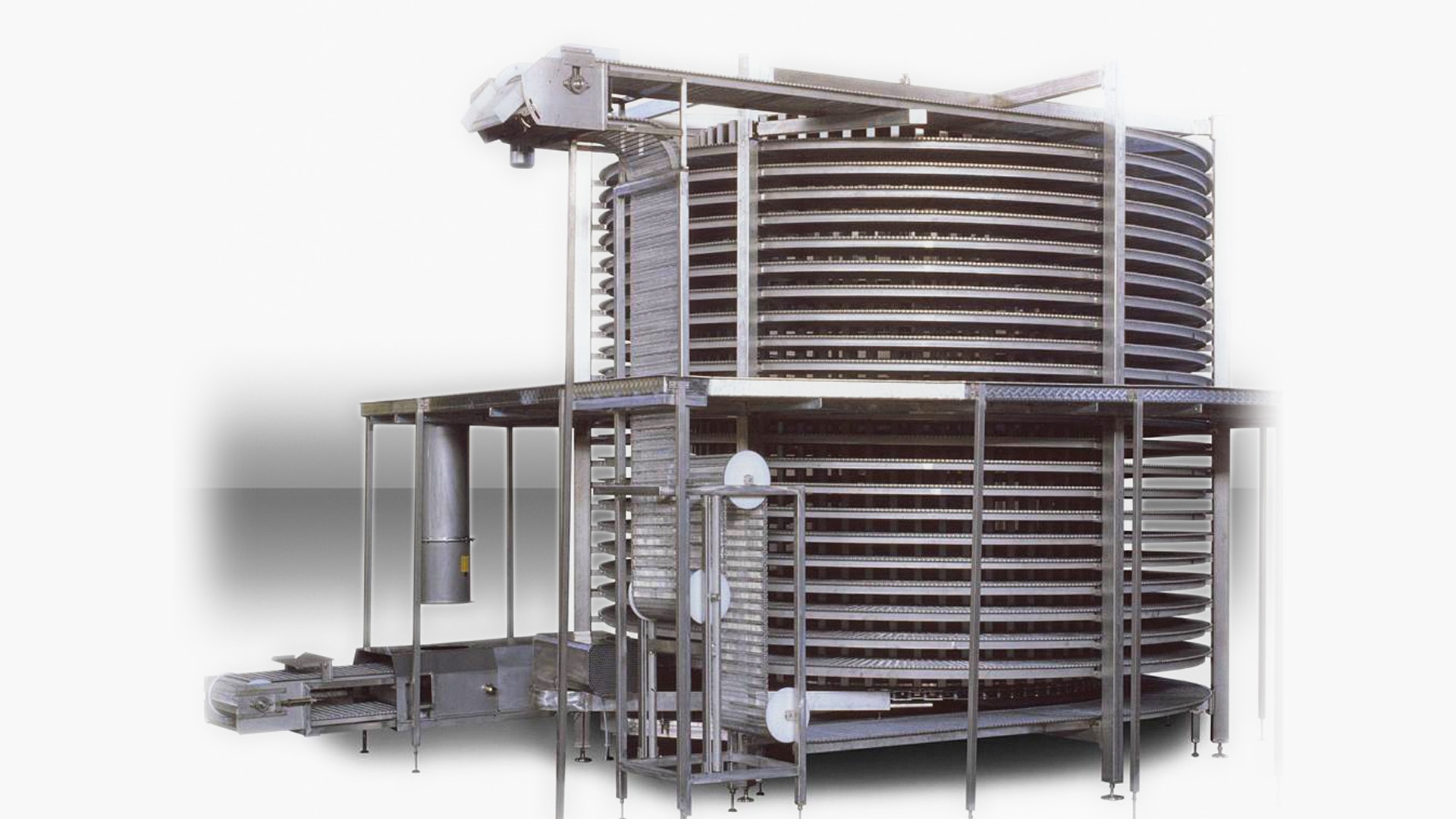

THERMAL TREATMENT

- Pasteurizers: complete range of thermal treatment tunnels for food and beverage products, containers, pasteurization and cooling.

- Spirals: complete range of thermal treatment spiral solutions, air and water flow technology, for pasteurization, cooling, refrigeration, cooking, proofing and drying for loose and packaged food products

- Drying: complete series of dryers, both batch and continuous belt type, to cover a wide range of applications.

- Sterilization/Batch Retorts: thanks to the extensive experience of our brand Levati Food Tech, we offer a wide range of sterilization/batch retort models designed to meet the highest food industry standard performances in terms of package integrity and respect of the organoleptic properties of the products.