Flow meter fillers for Food

We manufacture a full range of premium rotary fillers equipped with flow meter technology capable of filling a variety of food products, both viscous and smooth.

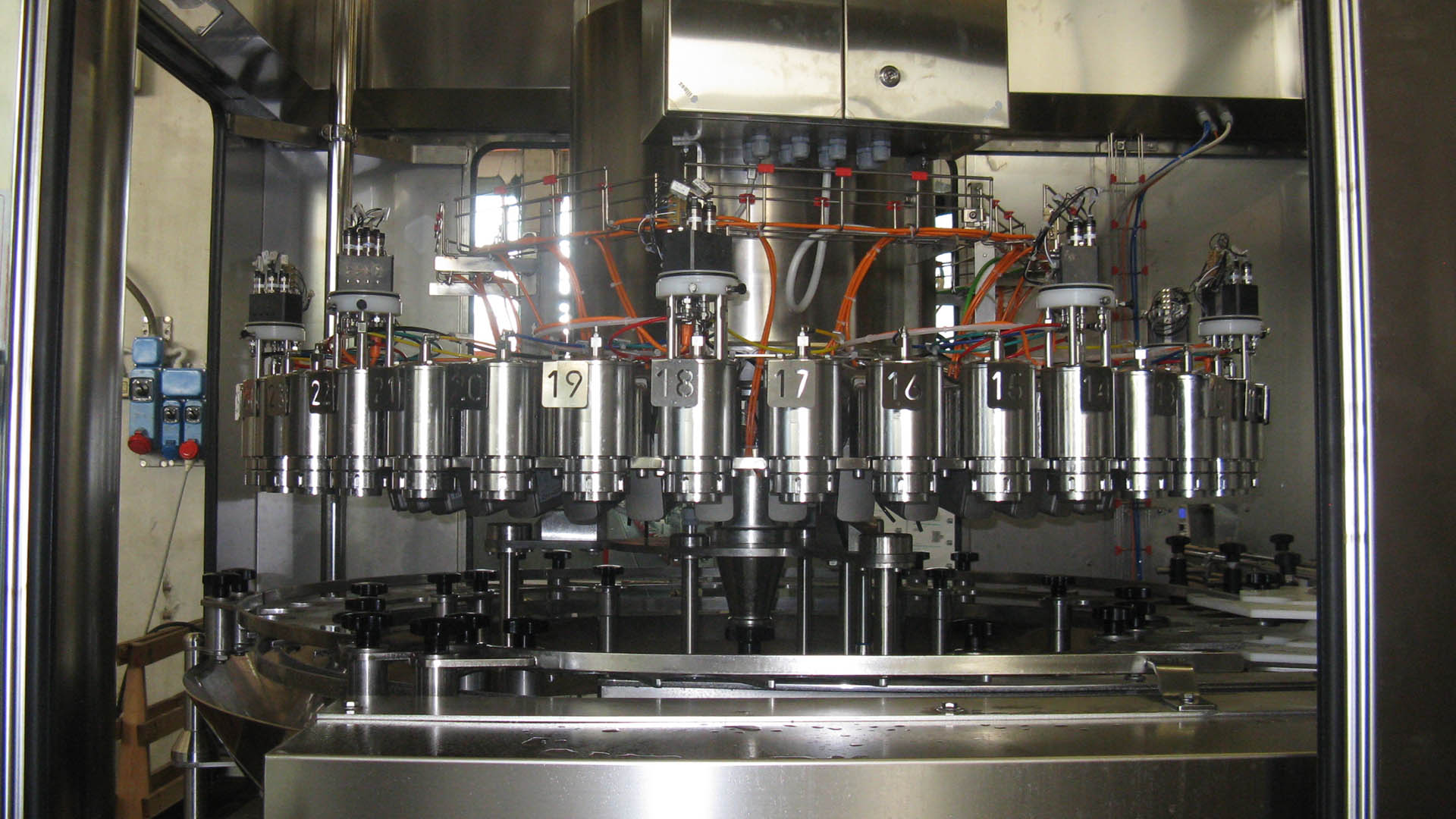

Magic Can FW

Volumetric fillers with flow meter technology, for food products. From 3.000 to 84.000 cph.

Volumetric filler with flow meter technology, suitable for formulated products. Available from 9 to 132 valves.

Products: formulated products

Formats: cans

Benefits:

- hot filling configuration as option

- high flexibility

- manual dummy cans as option

- filling valves controlled by PLC

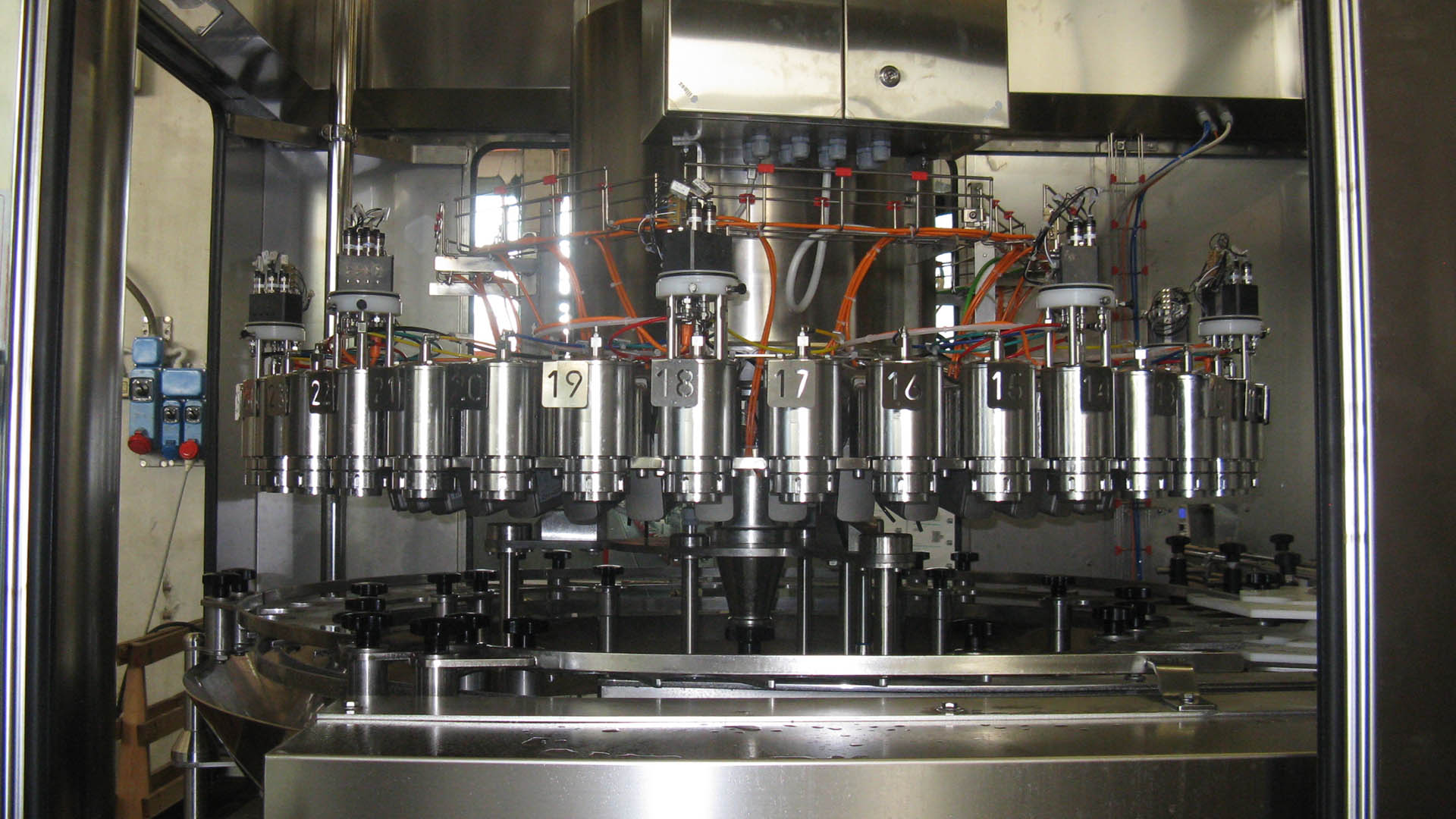

Magic FW

Speed from 5.000 up to 85.000 cph. Automatic filling machines specifically designed for hot/cold filling of viscous and smooth food products.

The filler with flow meters is an automatic machine designed for hot or cold filling of even viscous liquids if smooth.

PRODUCTS: strained baby foods, melted cheese, yogurt, tomato ketchup and paste, creams, pates, jam, honey, fruit pulp and juice

FORMATS: cans, glass jars and bottles, PET bottles

BENEFITS:

- Highly hygienic

- NO mechanical wear and consequently extremely low maintenance costs

- Constant filling accuracy whether dosing small or large volumes

- Possibility of synchronization with the seamer, in case of metal containers, or capper in case of bottles in glass or plastic

- Ability to fill even with highly aggressive products thanks to the use of flow meters in AISI 316L stainless steel

- Rapid size change-over AND Centralized lubrication system