All-in-one

Packaging machines made of premium materials and equipped with the most advanced technologies, able to handle every kind of format.

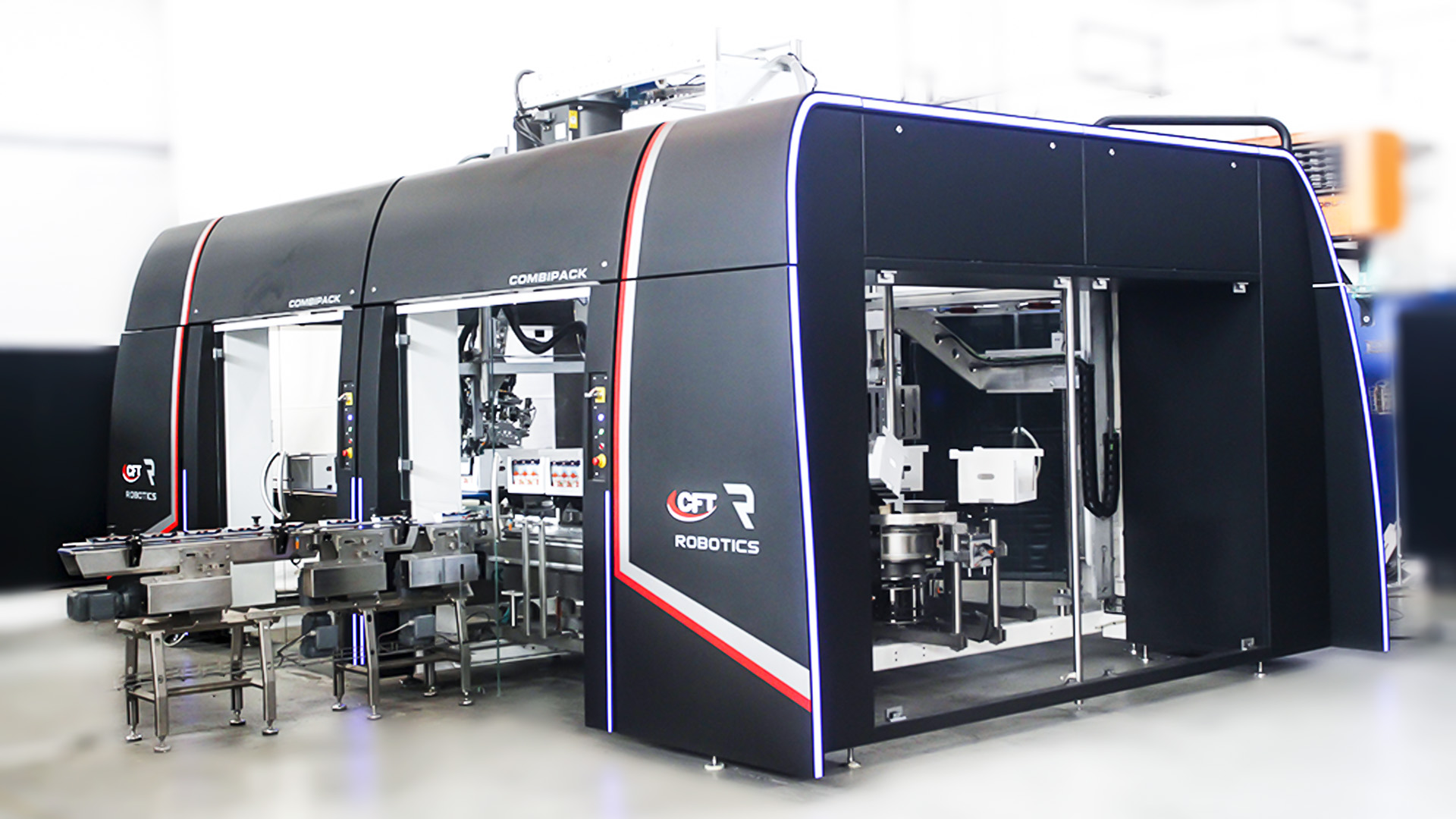

Among our range of Robotics solutions there are different models of modular systems, able to handle many formats and to reach different speeds. The all-in-one carton forming, filling and closing system Combipack is the top of this range.

Combipack 500 series

The Combipack 500 machine delivers a complete secondary packaging solution, offering multiple functions including carton erection, filling, closing and palletizing. This machine is particularly indicated for the forming and managing of small-sized cartons

FORMATS: all kinds of small-sized cartons

BENEFITS:

- FASTER PRODUCTION

- EASY CHANGEOVER

- INCREASED PRODUCTIVITY

- REDUCED COMPLEXITY

- EASY OPERATION

- FULL ACCESSIBILITY

ADV COMBIPACK

The ADV Combipack machine delivers a complete secondary packaging solution, offering multiple functions including carton erection, filling, closing and palletizing.

OVERVIEW

The machine’s frame, which can be made of coated or stainless steel, can be expanded lengthwise to incorporate different functions. Each modular body section is positioned between the two end-modules, with the number of sections being defined by the number of process steps required within the enclosed envelope of the machine.

From a control perspective, ADV Combipack is provided with a COMBI-AS solution, which comprises an Allen-Bradley® ControlLogix® programmable automation controller (PAC), which is used to deliver functionality to a number of motion axes driven by Allen-Bradley PowerFlex® 753 variable-speed drives or Allen-Bradley Kinetix® 550 servo drives.

In addition to these motion solutions, the machine is also equipped with two iTRAK® independent cart conveyor systems, called COMBI-MOVERS. They are used for product feeding and carton conveying during the forming, filling and closing operations.

Thanks to these features, the ADV Combipack is capable of handling multiple packaging formats, including American box, display box, wraparound, carton tray and combi case, with cartons being either top or side filled.

It also exploits a patented contactless technology to energize the vacuum pumps above the iTRAK® shuttles and is claimed to be the only packaging machine that forms the cartons directly above the shuttles.

FORMATS: every kind of carton format

BENEFITS:

- Faster Production

- Easy changeover

- Increased productivity

- Reduced complexity

- Easy operation

- Full accessibility