Evaporation technologies for energy saving

Which technology should you choose to increase the energy efficiency of your evaporators? Multiple effect, MVR or TVR?

The most suitable evaporation technology for each customer’s individual needs essentially depends on three factors:

- Energy costs

- The end product

- The energy efficiency

There are basically three evaporation technologies and they can be combined in various ways to maximize the energy yield of the whole system. In this article, we will review various technological solutions, starting with the most traditional and ending with the most innovative solution.

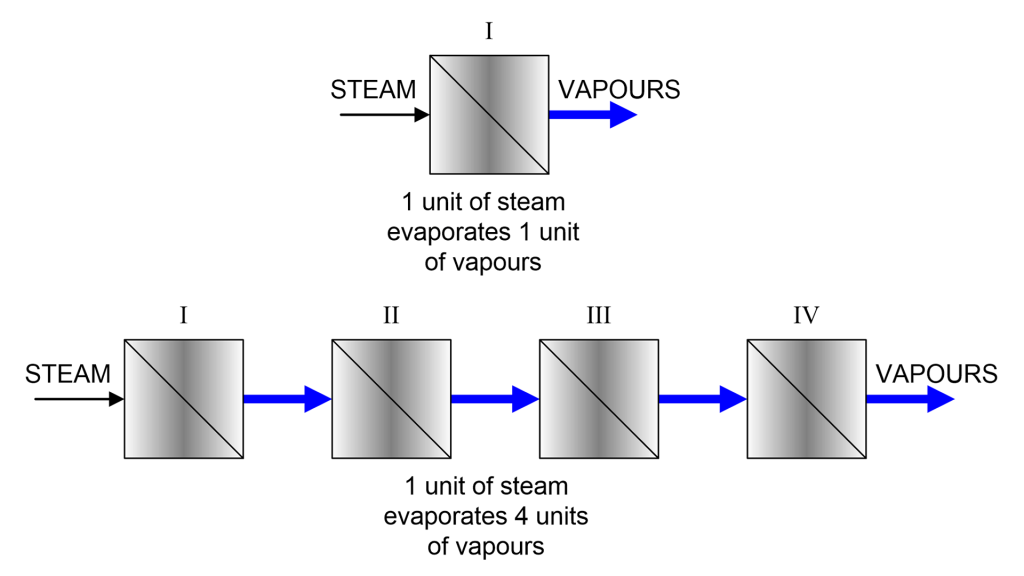

Multiple Effect evaporation technology

Multiple effect technology, as embodied in our Venus (for tomato paste), Mixflow (for fruit purees) and Poseidon (for fruit juices) evaporators, is a traditional type of evaporation. The ultimate goal is to achieve, by developing a multi-stage evaporation process, a concentrated product by subtraction of water, yielding approximately one kilogram of evaporated liquid from each stage of the system against one kilogram of vapour expended as heat energy. The efficiency of the evaporator is therefore equal to the number of effects: from single to fourfold (in the case of fruit processing, a larger number is implemented). Consequently, one unit of boiler steam evaporates one unit of product vapour in a single effect (1:1 efficiency) and four units in a quadruple effect (1:4 efficiency). In tomato paste production, the most economical solution in terms of investment and operating costs is the triple effect evaporator (1:3 efficiency).

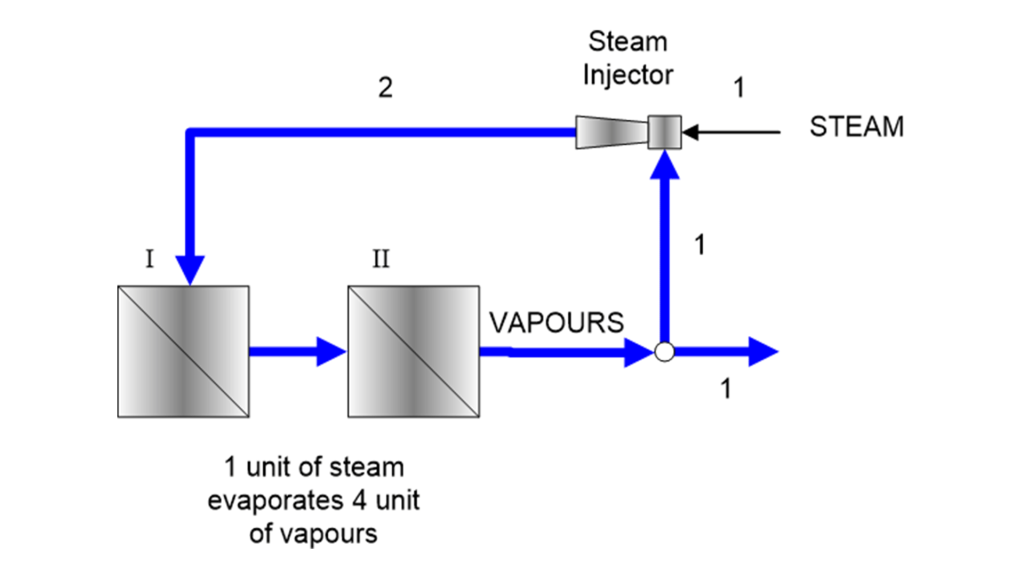

Picture 1 – Functioning of Multiple Effect Evaporation Technology

TVR evaporation technology

Thermal Vapour Recompression or TVR is a technology that uses the Venturi principle to recover low temperature product vapour by recompressing it with high pressure boiler steam. In this way, the boiler steam consumption is halved assuming a 10°C increase in temperature of the recompressed vapour.

MVR evaporation technology

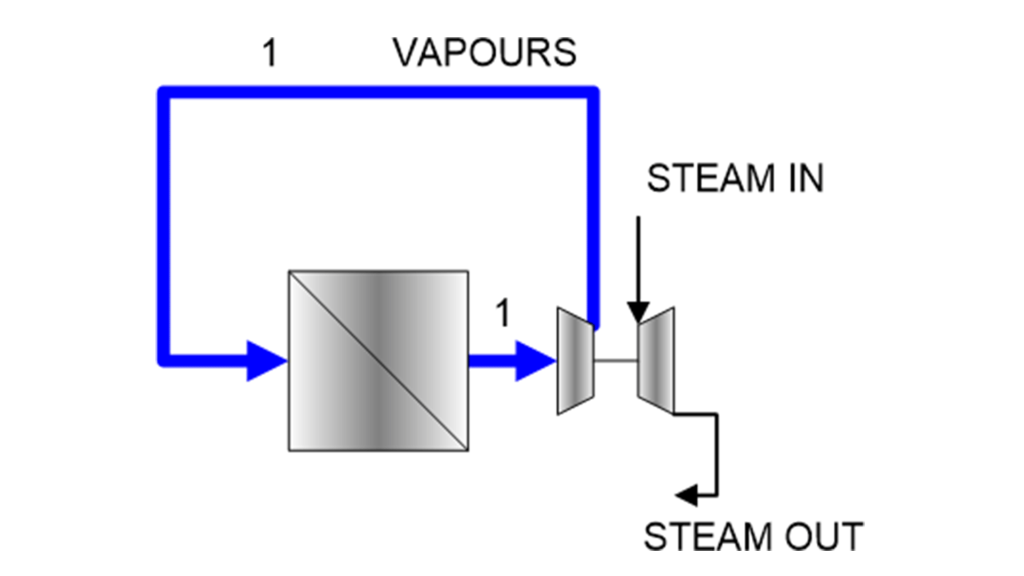

Mechanical Vapour Recompression or MVR is still the most energy-saving technology in evaporators for the food industry.

The MVR is based on the re-use of secondary vapour and its latent heat, produced by the evaporation system itself, as a heating source for the liquid undergoing evaporation. The temperature of the vapour generated in concentration is increased by its mechanical compression under saturation conditions. In this way, the recompressed vapour (by around 6-8°C) can be recycled through an exchanger, achieving a double objective:

- Zero boiler steam consumption

- Almost total reduction of the need for cooling towers to condense excess vapour

The most representative CFT solution of this energy-efficient technology is the Apollo MVR falling film evaporator.

Picture 2 – Functioning of MVR Evaporation Technology

The choice of compressor type for the MVR evaporator is the subject of a further energy-saving analysis. The MVR evaporator compressor can actually be powered by:

- An electric motor

- A steam turbine

When conditions in terms of services in the plant allow it, the turbine solution is preferred because it allows additional energy savings in electricity. It can be exploited to create a low-pressure network from the turbine’s own exhaust steam, which is recovered to feed plants downstream of the line, if present.

Combining different evaporation technologies

Different evaporation technologies can be combined to achieve further energy-saving advantages.

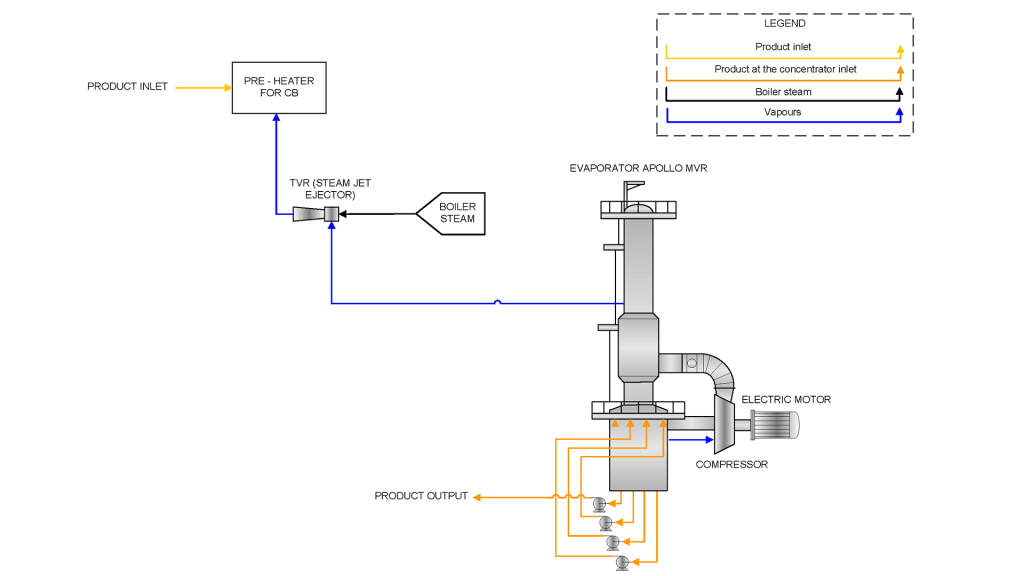

MVR and TVR as a pre-heating solution for products

To maximize the efficiency of the MVR evaporator, the incoming product must have a temperature above the internal boiling point of 75°C. This will allow the evaporation process to start from the top of the tube bundle, minimizing energy waste.

This is what happens when the product arrives at the MVR evaporator from a Hot Break (HB) heat treatment, whereas, if it arrives from a different treatment and at a temperature lower than the concentration temperature, it will have to be pre-heated. This is the case with Cold Break tomato paste, milk and fruit juices.

Picture 3 shows how two vapour recompression technologies can be combined to reduce the energy consumption required to preheat the product. This solution involves reusing part of the vapour that does not condense in the MVR evaporator calender (blue arrow on the left), to feed a TVR as it is in excess. With this configuration, the TVR increases the temperature of the incoming product with half the amount of boiler steam due to the recycling of vapour from the MVR evaporator.

Picture 3 – MVR and TVR as combined evaporation technologies for preheating

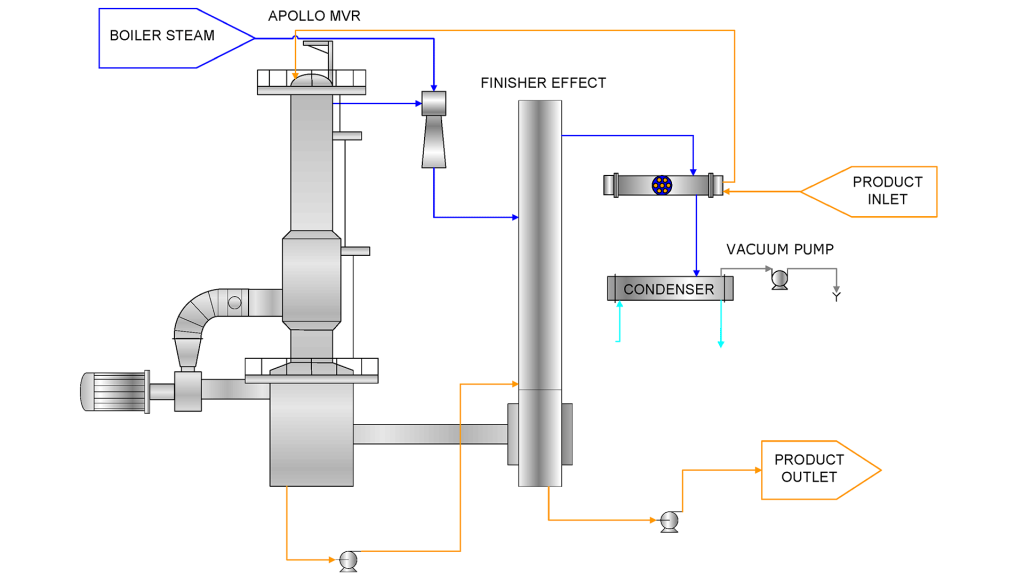

MVR and TVR as a solution for finisher efficiency

Combining MVR and TVR technology also applies when a finisher, i.e. an additional concentration column, needs to be installed.

There are many reasons why a finisher needs to be applied:

- In the case of fruit juices and liquid protein foods: these products are subject to the phenomenon of Boiling Point Elevation, abbreviated to BPE, which is the observed difference between the boiling temperature of the product and the vapour temperature of the product. The (product-vapour) temperature discrepancy erodes the Δt within the MVR evaporator, so that the addition of a finisher with a Δt higher than that of the MVR becomes necessary to finalize the concentration.

- The other case in which it becomes necessary to use a finisher occurs when the product leaving the MVR (e.g. tomato) is very viscous. To compensate for the reduction in the heat exchange coefficient, which tends to decrease with very viscous products, the temperature of the vapours to be fed into the finisher is increased. To achieve this in an energy-efficient manner, a small finisher with forced circulation is added.

In both cases, to decrease the steam consumption of the boiler needed to increase the steam temperature in the finisher (and thus the Δt), a TVR can be used and fed with a portion of product vapours from the MVR evaporator. These are recompressed with the same amount of boiler steam, which is then reduced by half.

Picture 4 – MVR and TVR as combined evaporation technologies for finisher efficiency

TVR as a solution for Multiple Effect efficiency

Thermal vapour recompression (TVR)is a technology that increases the efficiency of the multiple effect to which it is applied.

Picture 5 shows how the TVR technology works when applied to a double effect evaporator (1:2 efficiency). The vapour leaving the second effect is divided into two equal parts: one goes to the condenser, while the other is sent to the ejector to be recombined with the same amount of boiler steam, increasing its temperature by 10°C. The resulting mix of vapours returns to feed the first effect, initiating the new cycle. In this way, up to four kilos of product vapour can be evaporated with just one kilo of vapour: in other words, a double effect evaporator, to which TVR technology is applied, has the same yield as a quadruple effect, but a much lower investment cost.

Picture 5 – TVR and Multiple Effect Combined Technologies

Conclusion

The evaporation technologies considered apply to CFT evaporators, offering state-of-the-art, high-efficiency hybrid solutions. In particular, the MVR technology, applicable up to a maximum concentration of about 16°Bx corresponding to 83% of the total evaporated water, saves up to 98% of boiler steam thanks to the mechanical recompression of acidic vapours. It guarantees high quality end products due to low residence times and low Δt between product and heating vapours.

The excellent energy yield of this technology makes it possible to increase the energy yield of the entire line when used in combination with other, more energy-intensive types of evaporation such as the multi-effect option. The CFT hybrid evaporation solution is not only more efficient in terms of energy consumption than traditional evaporation, but also offers significant environmental and fiscal benefits, as well as better operating costs and production flexibility.