A new filling valve: innovation and versatility

Progress and innovation are rarely the result of a flash of genius out of context with the world around us and the needs of the market at that precise moment in time.

We have experienced this, and experience it in practice every day while developing our technologies. The studies carried out for the development of a new filling valve are no exception.

The new CFT valve, which features a no-contact arrangement, is suitable for filling various types of still products. The special hydraulic design, combined with the superior hygiene, allows the handling of products with particularly sensitive physical characteristics, such as condensed milk, while ensuring a very high degree of integrity in terms of consistency. It can be equipped with either manual or automatic “false cups” for use during the washing phases, which guarantee high standards of hygiene and cleanliness.

Thanks to its remarkable versatility, this solution, widely used in both the food and beverage sectors, can handle a wide variety of containers and be combined seamlessly with weight or flowmeter filling technologies. This flexibility is borne out by the numerous application contexts, from cold fill / hot fill systems to ultra clean setups.

The valve in its basic configuration is fitted with a pneumatic actuator capable of single flow operation. In response to specific technological requirements, it can be fitted with a dual-stroke unit that allows it to perform at high and low flow rates. Finally, there is a third configuration, also optional, equipped with an electric motor that guarantees maximum operating flexibility with the option of varying critical parameters and modulating the filling flow rate.

Already in the design phase, the filling valve is fully configurable. The aim is to pre-determine the optimal set-up in line with the actual technical and technological requirements.

The new filling valve: a study based on sweetened condensed milk (SCM)

It all came about as a result of feedback from a customer.

The request was to develop and test a state-of-the-art, hygienic and versatile solution that would solve a problem that is always present during the filling of sweetened condensed milk: deconstruction.

Effectively, inside plants and during filling, the structure of the product undergoes such mechanical stress as to compromise its physical characteristics. Sometimes this effect is irreversible.

In these circumstances, the texture of the outgoing product is crucial as it allows it to be properly processed in the pastry and confectionery sector.

We therefore decided to develop this new valve in order to enable its application in particularly critical contexts, such as the world of condensed milk.

Development and testing of the new filling valve

A laboratory study was launched, aimed at detecting the texture parameter, which can be summarized in four main phases:

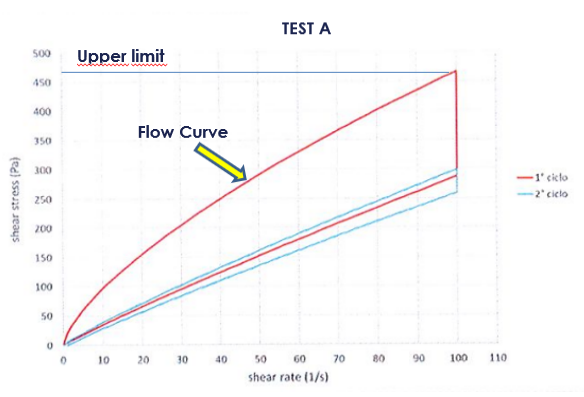

- Test A: measuring of “virgin” product samples, aimed at establishing their initial physical characteristics.

Graph 1. Virgin product flow curve

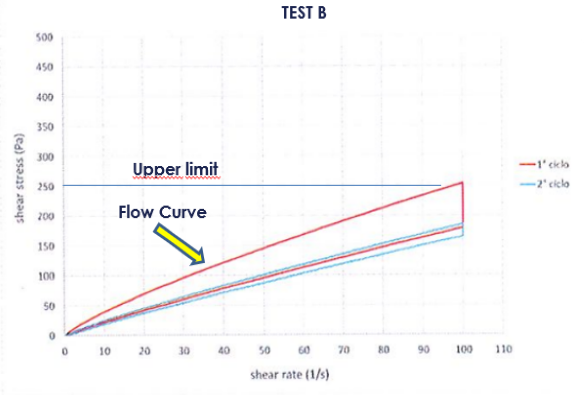

- Test B: The product undergoes an initial hydraulic stress in the feed circuit on the laboratory unit, equipped with a pump.

The intention was to replicate real system conditions. At the end of this phase called FHS (First Hydraulic Stress), a second measurement was taken. This took a snapshot (see Graph 2) of the real physical conditions of the product before filling.

Graph 2. Product flow curve after passing through the pump

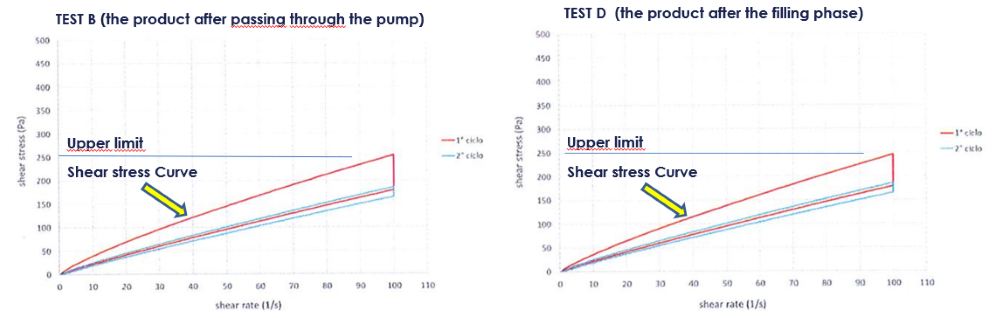

- Subsequent tests: Following the FHS phase, several filling cycles were carried out under different set-up conditions.

The aim was to identify a filling solution that would not generate further destructuring of the product. The flow curve of Test B (left graph) is caused by the passage of condensed milk through the pump. The upper limit of the curve is approximately 250 Pascal. After the filling test, Test D (graph on the right), we can observe the same result: no change in consistency was detected. This confirms that, under specific hydraulic conditions, the new valve allows ‘gentle’ filling, which perfectly preserves the texture of the product.

Graphs 3-4. Stress suffered by the product after passing through the pump vs. stress suffered by the product after filling

These results have consequently established the technical validation of the new valve, which is also ideal for handling particularly delicate products.

The above results were achieved thanks to the invaluable collaboration of the Parma Experimental Station, which generated a complete dossier on product viscosity, a fundamental characteristic for monitoring the degree of deconstruction in a variety of contexts.

Objectives achieved and future prospects

The scientific approach, supported by reliably documented data and laboratory tests, is an important competitive edge for us and allows us to continuously offer new solutions and updates for our regular and future customers. This project is an example of a new solution identified thanks to a process based on data and experimentation, which is crucial to understanding, anticipating and guiding the needs of an ever-changing market and world.

Roberto Puglia – CFT Filler Product Manager