Pasteurizing equipment for vegan food

More and more vegans

We all know it: in recent years there has been a dramatic drop in consumer interest in products of animal origin, mainly due to the growing concern for animal welfare, personal health and sustainability. This is one of the reason why pasteurizing equipment for vegan food and other similar technologies have become popular in the Food and Beverage Industry.

The consumption of animal protein in certain cases can be associated with raised levels of cholesterol, fats and calories, that increase the risk of heart disease, high blood sugar levels and obesity; for these reasons, people are demonstrating an inclination towards vegan sources of protein. This has created the basis for the growth in the market for tofu, vegetable burgers and all those foods that are seen as “healthy alternatives” to meat.

Following this trend, many companies have been created that offer an ever-increasing portfolio of tofu products to attract consumers, such as “premium” category tofu, tofu enriched with omega-3, vacuum-packed tofu, tofu cutlets and so on. One of the main challenges of this market is the shelf-life and food safety of tofu-based products.

Australian Eatwell and pasteurization

Australian Eatwell is a company that was founded in 1990 and specializes in the production of tofu and vegetable burgers, foods that are also becoming increasingly popular in Australia. Eatwell’s management contacted CFT Group in 2019 with a specific need: the goal was to raise its quality and safety standards during production, in particular they were looking for the most safe and effective pasteurizing equipment for vegan food, especially for tofu and veggie burgers.

Pasteurizing this type of food has the advantage of being a much less aggressive process than sterilization, it preserves the organoleptic characteristics of the product and allows the shelf life to be extended up to 45/60 days in the fridge.

Pasteurization technologies can vary. Pasteurizing ovens and tunnels fall into this category, even if sometimes, especially if not used with the right procedures, hygienic pitfalls can be hidden thus not allowing the levels of food safety to be met as required by the market. The real risk that many companies which do not dedicate the right resources to these operations run is to fail to pass quality controls and have their products rejected by customers or large-scale distributors, with consequent serious economic and image damage. In our experience, this happens more often than we think.

CFT Group pasteurizing equipment for food

The solution that we designed for Australian Eatwell goes in the opposite direction: 100% safety and quality.

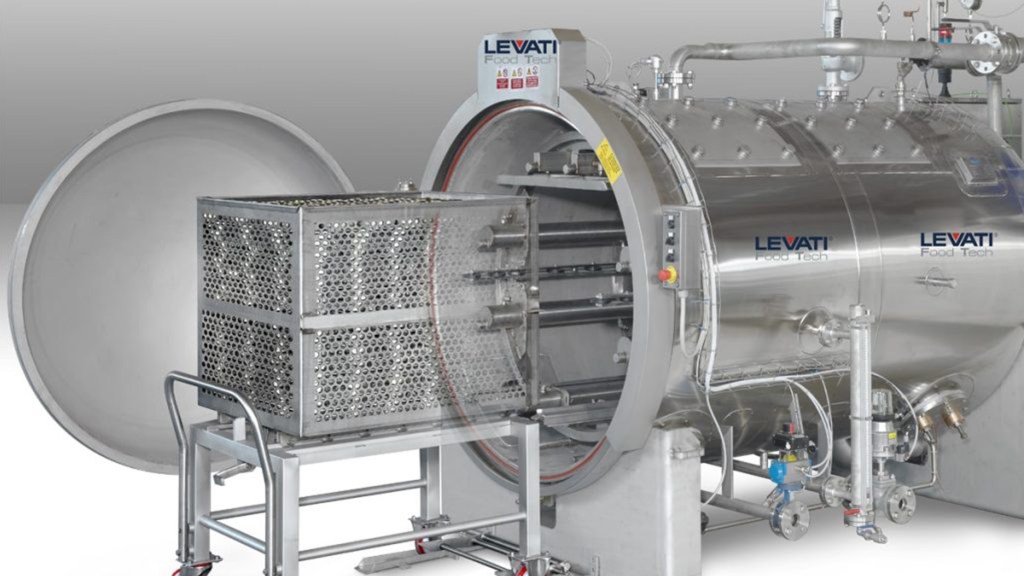

To guarantee “state-of-the-art” pasteurizing equipment for vegan food, we proposed the use of a two-cycle static autoclave. In addition to allowing safe and easily manageable processing, this type of technology has the advantage of returning the product to 6-7 degrees once the pasteurization is finished: this means that you do not have to use a blast chiller in the next stage. Other characteristics of this autoclave are a fully automated control system, energy saving, a perfect uniformity in the distribution of the internal temperature and a correct and documented recording of the thermal cycle.

Of course, we are talking about a greater investment when compared to a pasteurizing oven or tunnel. For this reason, Eatwell also considered other types of technology and different autoclave models. The goal, however, was to not take any risks with quality and safety and the decision in the end was to award our project.

Market prospects*

The global market for tofu and derivative products is expected to grow at a CAGR of + 5.1% in the 2020-2025 period.

The market is driven by a growing preference for plant-based products, with a shift of consumers towards a vegan diet. In addition, the rich nutritional profile of tofu is fuelling its demand globally.

*source: mordorintelligence.com