- YOUR PRODUCT

- AUTOMATION SOLUTIONS

- TECHNOLOGIES

- SERVICES

- RESOURCES

- About Us

- Brands & Affiliates

- Quality

- Environment

- Locations

- Careers

- Contact

- SEGMENTS

- AUTOMATION SOLUTIONS

- CAPABILITIES

- SERVICES

- RESOURCES

Your Product

From contact lenses to mail-order pharmacies, ATS Life Sciences Systems has a long history of providing automated manufacturing solutions for the assembly and handling of a broad range of products.

Automation Solutions

We’ll custom design or help you find the right machines for your Assembly, Material Handling, Conveyance, Manufacturing, Vision Testing, Software (IIoT) needs

SERVICES

Our ability to assist you with your project begins with understanding your product and processes. Whatever the stage of your product’s life cycle—product design, product iteration, clinical trials, or full commercial production—ATS Life Sciences Systems can complement your staff with CGMP-experienced consultants, engineers, and skilled trades and service people

Resources

A deeper dive into information and details about LSS solutions, from the experts who work on them every day.

Sign up for Life Sciences News and Updates

Cam Drive Magnetic Linear Mover

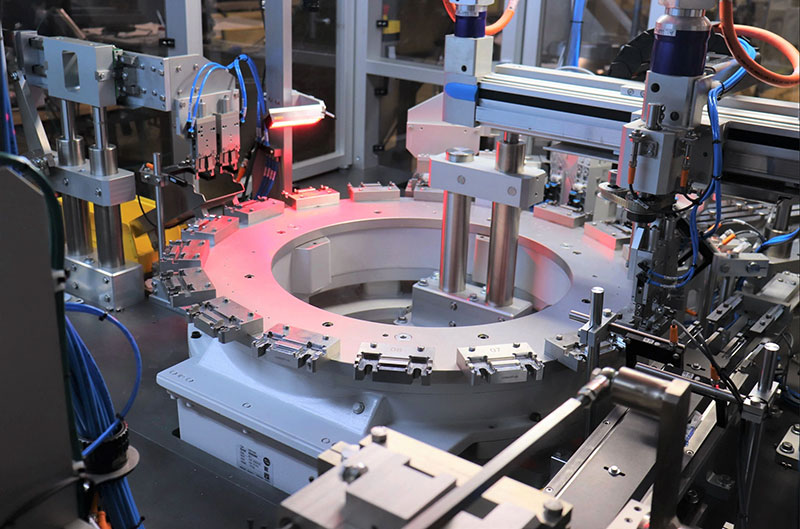

ATS OMNITRAK™

Can be designed with fully synchronous, asynchronous, or continuous motion segments within one cell. Highly customizable to almost any application—using servos, mechanical cams, or pneumatic cylinders

ATS OmniTrak

An assembly platform that combines the precision of cam-controlled workstations and the flexibility of servo-driven workpiece carriers offering high flexibility, lower maintenance

- Able to mix 1-one up stations with multi-up seamlessly on the pallet loop

- Low floor space requirement

- Low noise level down to 70dBa (process dependent)

Overview

Recommended For

Applications where many complex transformations are required in the assembly process

Glass or plastic syringes, injection pens (pen body, pen needle)

Specs

Cycle rate

Typically 30 – 60 up to 200 cycles per minute (CPM)

Pallet deck

Fully customizable

Customizable pallet design

allows pallets to carry a number of different components

Ability

to combine 1-up stations with multi-up (2, 3, 4) stations seamlessly on the pallet loop

Requirement:

Low floor space

Size:

Track configurable in 1m segments

Motion platform

Synchronous/asynchronous/continuous motion platform options

Low maintenance

cost and duration

Interfaces

Ethernet IP, Powerlink, Profinet, EtherCAT

Packages:

Service and maintenance packages available

Positional accuracy

of ± 0.01mm

Key Features & Benefits

- Fully assembled, integrated and tested platform, ready for plug-and-play operation

- Expandable I/O

- Low noise level down to 70dBa (process dependent)

- Options: Synchronous, Asynchronous, Continuous motion

Application

- Gentle product handling

- Station cam tooling can be synchronized to/from pallet motion

- Expandable at the station and module level

Key Benefits

An optimized solution that is robust, reliable, quiet, cost-efficient and easy to maintain

Fewer Moving Parts

The OmniTrak platform requires less maintenance, resulting in reduced wear on the machine and increased cost savings for your company

Cam-driven Processes

Embedded control of servo motors with support for electronic camming; combination cam-driven reliability with asynchronous programmability and flexibility

Customizable Software

The ability to run synchronous, asynchronous and continuous motion processes on the same platform. Decouple variable processes and then resynchronize at the individual station level

Configurability

Create exclusive machine layouts tailored to meet your individual needs; optimize by station (# UP), number of pallets, mode of operation, station index time

Other Assembly Solutions

An assembly platform offering high flexibility, lower maintenance

Our engineers develop customized or standard solutions based on our tried and trusted platforms. Let us help you find the ideal solution.

GET IN TOUCH

Briefly tell us about your automation needs and we’ll get back to you.

👋 Looking for something? I'm Gears and am happy to help.

Contact Us

Contact Us  Subscribe

Subscribe  LinkedIn

LinkedIn  Youtube

Youtube