We offer custom automation solutions and assembly lines for all process steps based on well-proven technology platforms like the SuperTrak ConveyanceTM, SuperTrak MICROTM, OmniTrakTM, DiscoveryTM, JetwingTM and our latest technology called SymphoniTM technology.

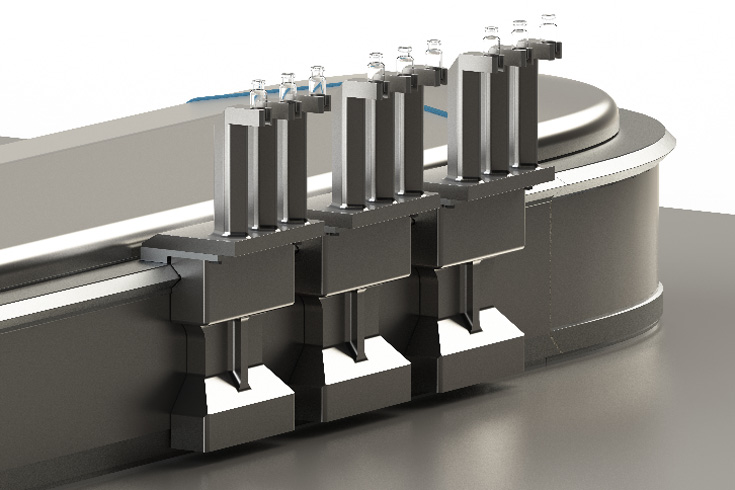

ATS SuperTrakTM – Asynchronous Linear Conveyance Platform

SuperTrak CONVEYANCE™ products include, SuperTrak GEN3™ and SuperTrak MICRO™ conveyors. SuperTrak GEN3™ and SuperTrak MICRO™ are smart enabled technologies that get machines to production faster and more effectively than traditional methods by saving significant engineering and integration time. The TrakMaster™ software included with the SuperTrak GEN3™ platform is the user interface that provides access to the track’s powerful integrated functionality.

ATS SuperTrak GEN3

- Straight Section: 1000 mm

- 180-Degree Section: Narrow – 500 mm turning radius / Wide – 800 mm turning radius

- Product Fixture Width: 155-500 mm

- Maximum Speed: 4m/s

- Acceleration: 1G with 10 kg payload / 4G with 1 kg payload

- Payload: 10+ kg per shuttle

- Process on Curve: Full control

- Carrier Options: Standard mover configuration with 2 or 3 magnet array options

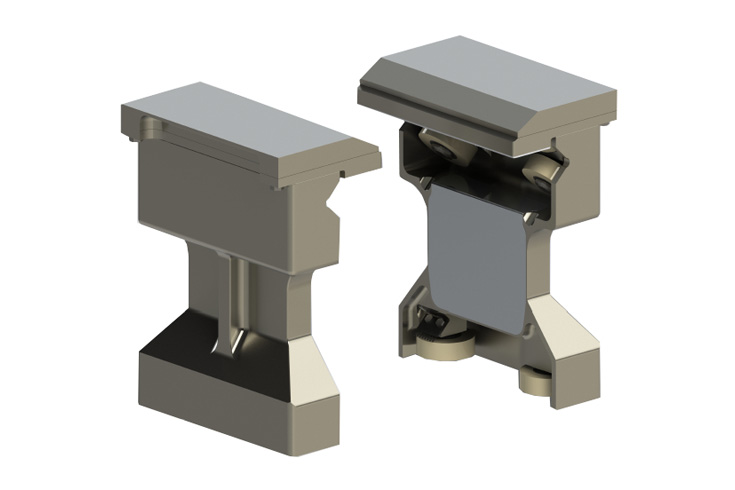

ATS SuperTrak MICRO

- Motor Length: 660 mm

- Product Fixture Width: 50-150 mm

- Maximum Speed: 3m/s

- Acceleration: 1.5 g with 1.5 kg payload 5 g with 0.25 kg payload

- Payload: 1.5kg for a 50mm shuttle and 3kg for a 100mm shuttle

- Communication: Ethernet/IP, PROFINET, discrete I/O**

- Process on Curve: Yes, full control

- Carrier Options: Standard mover configuration with 50 or 100 mm magnet array options

ATS SymphoniTM – Synchronous High Performance Digital Assembly Solution

Our ATS SymphoniTM is a digital assembly automation technology featuring an unmatched combination of speed, versatility, and precision. It delivers business value in a scalable, modular platform that merges the best features from each – the digital flexibility of robotics and linear motion conveyance, the high output, cam-driven efficiency of continuous motion, synchronous indexing machines as well as the line–balancing power of intelligent pallets.

Operating Features

- Robotic Stroke Rate: up to 200 per minute

- Operations: 1-up to 4-up with digital, friction-free radial orientation.

- Library of standard, selectable motion profiles

- Library of standard robotic end-of-arm “decks”

- Fine Adjustment of Axes through HMI: 0.01 mm increments

- Flexibility: Ability to leverage a given workstation to do multiple operations

Physical Construction

- SuperTrak™ Spine: configurable and extendable in 1 m sections

- Standard Modules: 1 m and 2 m

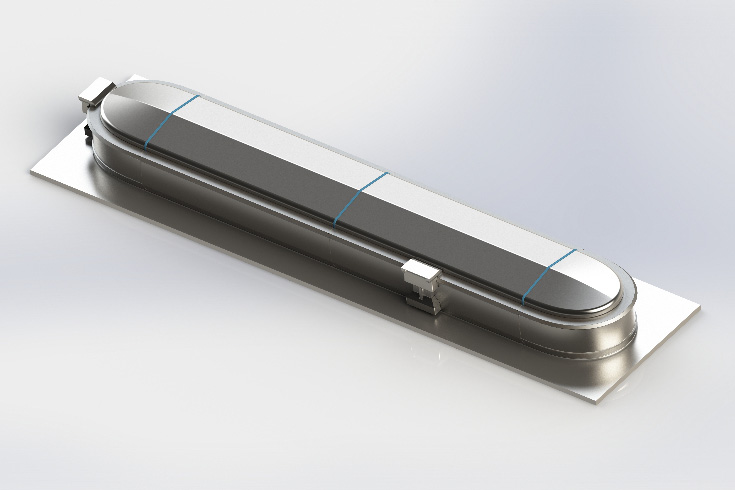

ATS OmniTrakTM – Combined Linear Assembly Solution

Our ATS OmniTrakTM is an unique assembly system technology that has been proven in production for many years. It combines the precision of cam-controlled workstations and the flexibility of linear motor-driven workpiece carriers (ATS Supertrak ConveyanceTM). This system offers high flexibility for products and processes, as well as a lower maintenance and space requirements.

- Cycle Rate: Up to 200 cycles per minute

- Number of Pallets: Fully configurable

- Pallets Size: Fully customizable

- Options: Synchronous, Asynchronous, Continuous motion

- Size: Tracks configurable in 1m segments

- Interfaces: Ethernet IP, Powerlink, Profinet, EtherCAT

ATS DiscoveryTM – Synchronous Rotary Indexing Assembly Solution

Our ATS DiscoveryTM dial machine is a standardized, cam driven platform that ATS has refined and successfully implemented throughout the industry for decades. It achieves high production performance due to the high repeatability of cam driven stations and easy maintenance. The dial movement is generated by an indexer coupled to the main drive shaft producing a synchronized machine.

- Cycle speed: Up to 150 cycles per minute

- Stations: up to 20 (standard)

- Number of tracks: up to 12

- Options: special versions such as two interlinked rotary indexing machines

- PLCs: Siemens S7 or Allen Bradley CLX

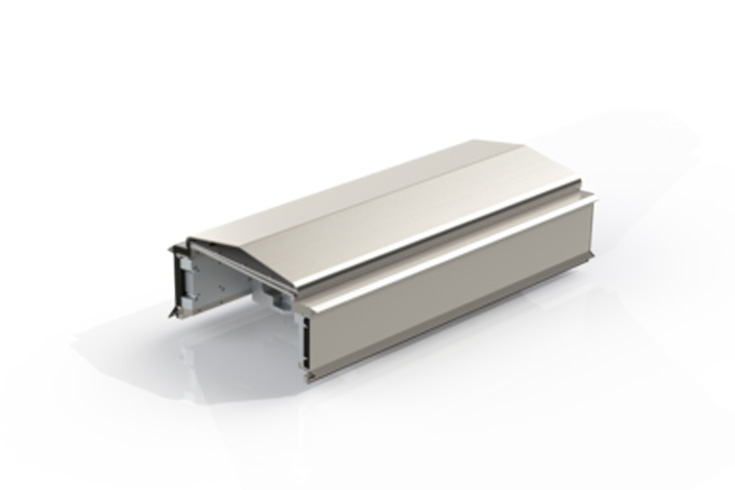

ATS JetwingTM – Synchronous Linear Assembly Solution

Our ATS JetwingTM is an exceptionally versatile, compact, linear assembly platform. It supports up to 12 stations and is ideal for the product development phase and assembling large quantities of products with short lifecycles. The system is capable of both semi- and fully-automatic assembly. Quick retools, combinations of stations via interfaces, introduction of new stations/modules or product changes are one of the greatest features of the system.

- Number of Stations: up to 12

- Number of Tracks: multiple-track assembly possible

- Cycles: infinitely variable, up to 80 cycles per minute

- Positional Accuracy: +/-0.02 mm

- Pallet Dimensions: 100×100 mm and 200×100 mm

- Indexing Time: 0.2 seconds (with 100 mm feed)

- Basic Dimensions: 1120 x 1540 x 2300 mm

- Cleanrooms: Suitable up to class 10,000 / ISO 7